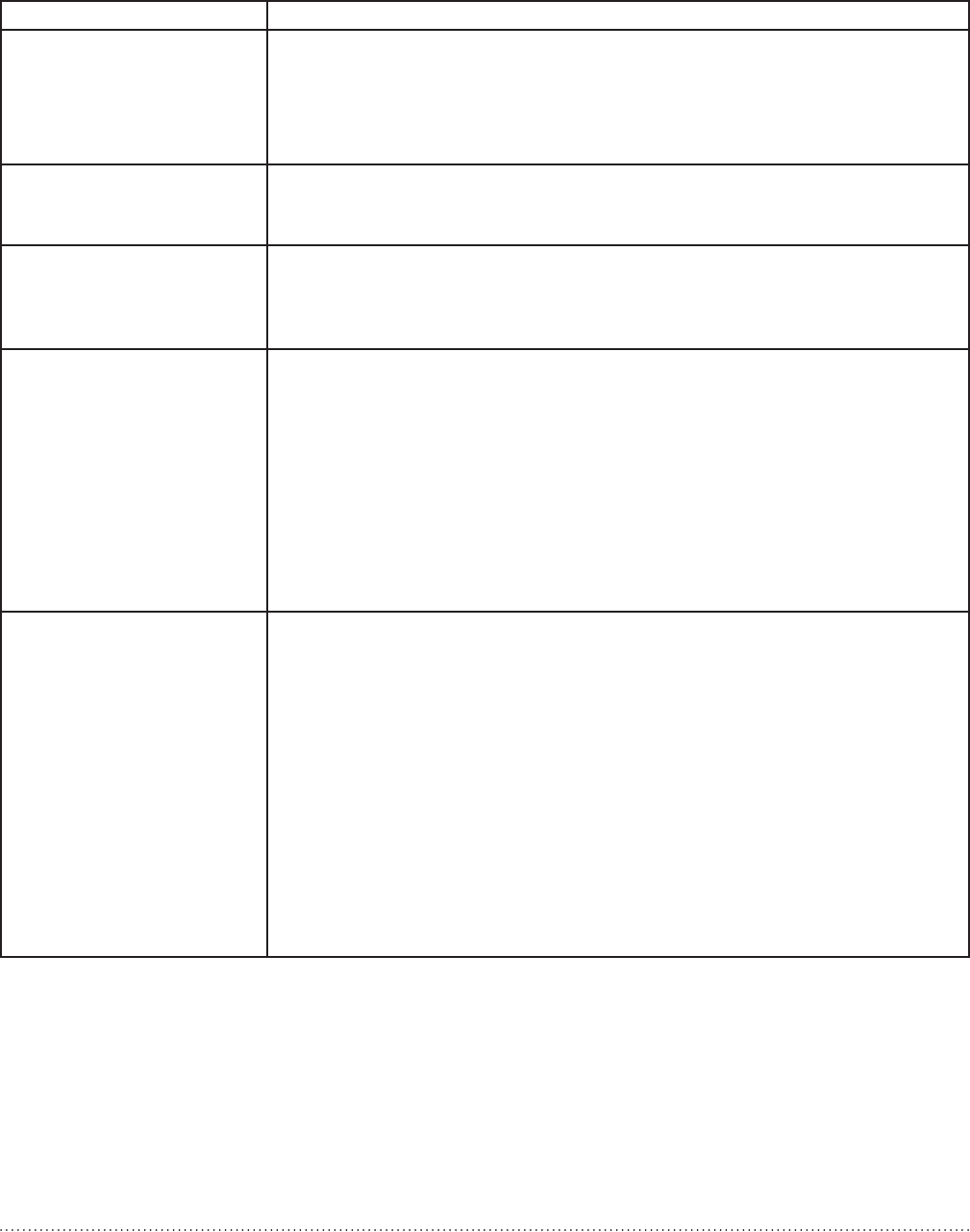

Troubleshooting (continued)

Problem Recommended Troubleshooting Steps

Fan does not run with

ventilation activated.

Compressor runs briefly

but cycles on & off with

humidity control turned to

ON.

1. Loose connection in fan circuit.

2. Obstruction prevents fan rotation.

3. Defective fan.

4. Defective fan relay.

5. Defective fan capacitor.

Evaporator coil frosted

continuously, low de-

humidifying capacity.

1. Defrost thermostat loose or defective.

2. Low refrigerant charge.

3. Dirty air filter(s) or airflow restricted.

Unit not providing

ventilation.

1. Check control wire connections (check connections at fresh air damper

also).

2. Defective fresh air damper.

3. Dirty air intake. Clean outside intake hood.

Unit removes some

water, but not as much as

expected.

1. Air temperature and/or humidity have dropped.

2. Humidity meter and or thermometer used are out of calibration.

3. Unit has entered defrost cycle.

4. Dirty air filter.

5. Defective defrost thermostat.

6. Low refrigerant charge.

7. Air leak such as loose cover or ducting leaks.

8. Defective compressor.

9. Restrictive ducting.

10. Optional Condensate Pump Safety Switch open.

Unit Test to determine

problem:

1. Detach field control wiring connections from main unit.

2. Connect the R and FAN contacts from the main unit together; only the

impeller fan should run. Disconnect the wires.

3. Connect the R and DHUM contacts from the main unit together; the

compressor and impeller fan should run.

4. If these tests work, the main unit is working properly. You should check

the control panel and field control wiring for problems next.

5. Remove the control panel from the mounting box and detach it from the

field installed control wiring. Connect the blue, yellow, and green wires

from the control panel directly to the corresponding colored pigtails on

the main unit. Leave the violet, white, and red wires disconnected!

6. Turn on the humidity control. The compressor and impeller fan should

run.

7. If these tests work, the problem is most likely in the field control wiring.

Refrigerant Charging

If the refrigerant charge is lost due to service or a leak, a new charge must be accurately weighed in. If any

of the old charge is left in the system, it must be recovered before weighing in the new charge. Refer to the

unit nameplate for the correct charge weight and refrigerant type.

Compressor/Capacitor Replacement

This compressor is equipped with a two terminal external overload and a run capacitor, but no start

capacitor or relay.

TrueDry DR65 Dehumidication System 69-2089EFS—11

14