14 – English

ASSEMBLY

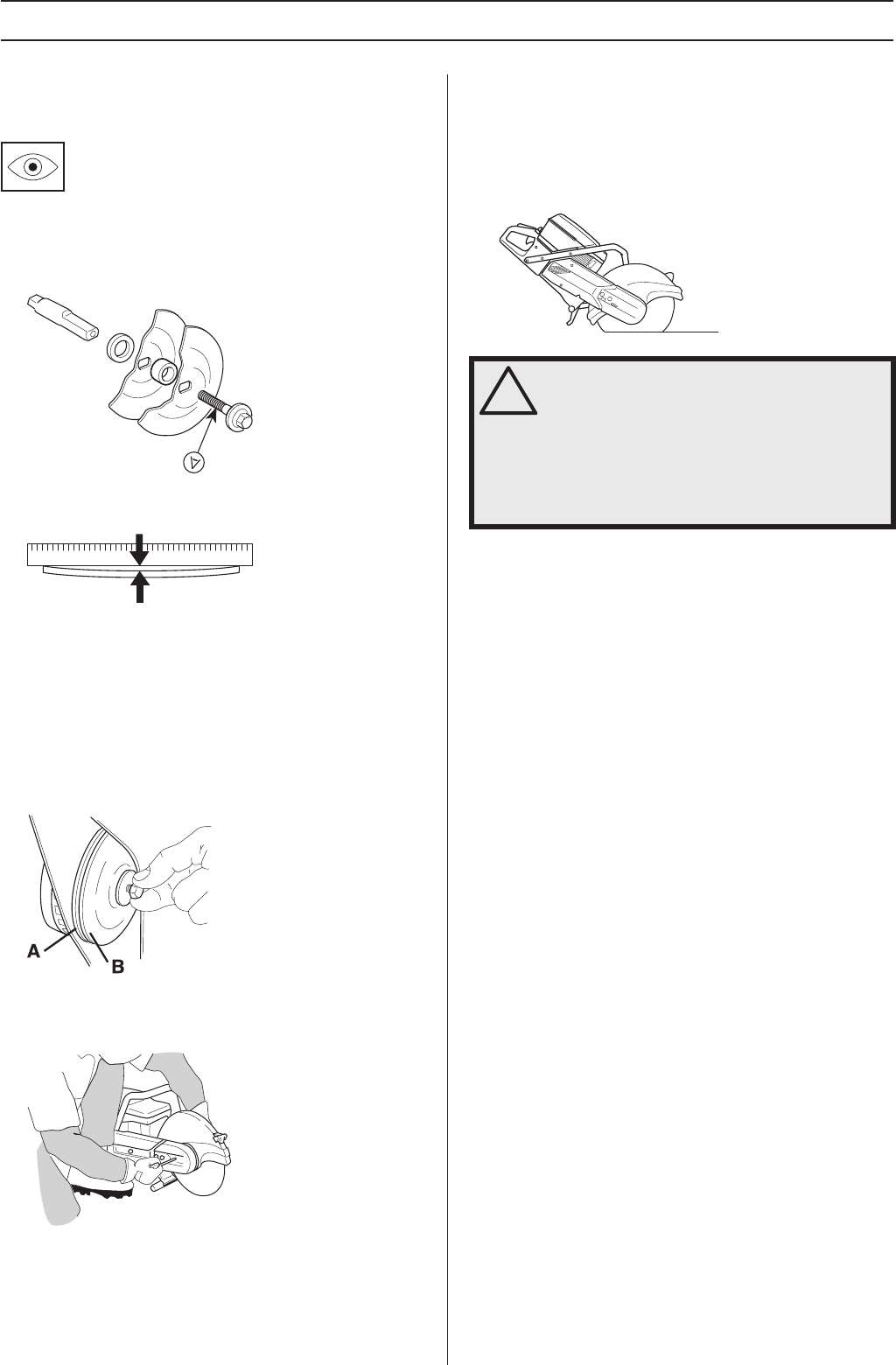

Checking the drive axle and flange

washers

Check that the threads on the drive shaft are undamaged.

Check that the contact surfaces of the cutting blade and

flanges are flat, run correctly on the spindle and are free from

foreign objects.

Do not use warped, notched, indented or dirty flange

washers. Do not use different dimensions of flange washers.

Fitting the cutting blade

Husqvarna cutting blades are manufactured and approved for

freehand cutting. The paper labels on each side of the blade

are there to distribute the pressure from the flange washer

and prevent the blade from slipping.

The blade is placed on the bushing between the inner flange

washer (A) and the flange washer (B). The flange washer is

turned so that it fits on the axle.

The shaft can be locked using a screwdriver, steel pin or the

like. This is slid in as far as possible. The blade is tightened

clockwise.

Tightening torque for the bolt holding the blade is: 15-25 Nm

(130-215 in.lb).

Guard for the blade

The guard must always be fitted on the machine. The guard

for the cutting equipment should be adjusted so that the rear

section is flush with the work piece. Spatter and sparks from

the material being cut are then collected up by the guard and

led away from the user.

!

WARNING! A 16 inch blade guard should

only be used on power cutters initially

equipped with a 16 inch blade guard. If a

guard obtained as a spare part is fitted on a

power cutter which is equipped with a 12 or

14 inch guard, a 16 inch blade will run too

fast. A cutting blade running at a too high

speed can break or cause serious damage.