English – 17

MAINTENANCE

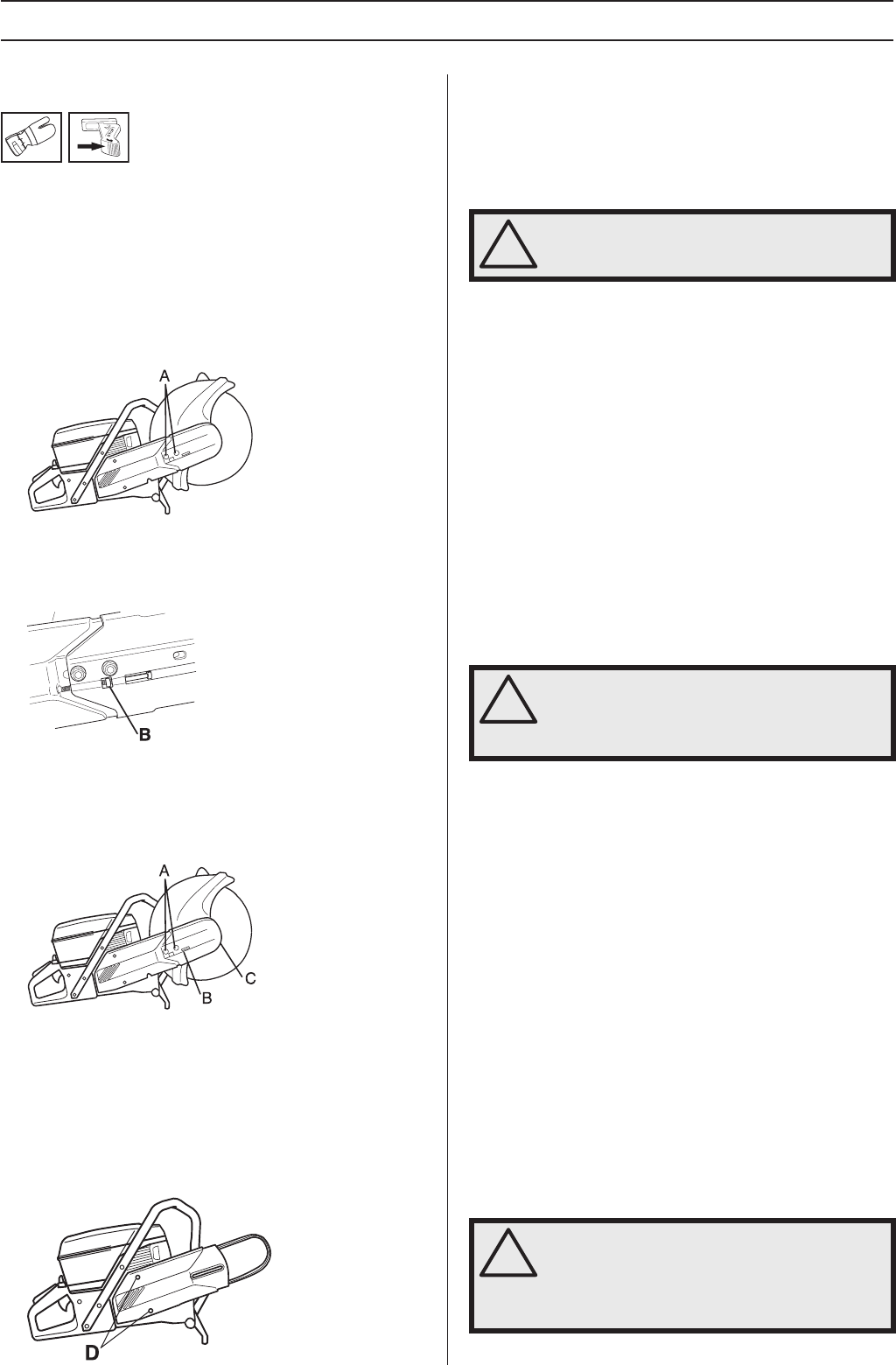

Tensioning the drive belt

• When the machine is equipped with a friction retarder, a

scraping sound can be heard from the bearing housing

when the blade is turned by hand. This is quite normal.

Please contact an accredited Husqvarna workshop if you

have any questions.

• The drive belt is fully enclosed and well protected from

dust and dirt.

• When tensioning the drive belt, slightly loosen the nuts (A)

holding the cutting head and belt guard.

• Turn the tension screw so that the nut (B) aligns with the

arrow on the guard. Shake the head to ensure the spring

can tension the belt. The belt now automatically has the

right tension.

• Tighten the nuts holding the cutting head.

Replacing the drive belt

• Loosen the two screws (A).

• Turn the tension screw (B) until tensioning stops.

• Remove the two screws (A).

• Remove the front belt guard (C)

• Remove the belt from the belt pulley.

• Remove the cutting head.

• Remove the screw (D). Remove the side cover.

• Replace the drive belt.

• Assemble in the reverse order as set out for dismantling.

• Check that the blade guard over the cutting blade is not

cracked or damaged in any other way. Replace when

damaged.

Belt pulley and clutch

Never start the engine when the belt pulley and clutch are

removed for maintenance.

Carburetor

Your Husqvarna product has been designed and

manufactured to specifications that reduce harmful

emissions. After the engine has used 8-10 tanks of fuel the

engine will be run-in. To ensure that it continues to run at peak

performance and to minimise harmful exhaust emissions

after the running-in period, ask your dealer/service workshop

(who will have a rev counter at their disposal) to adjust your

carburettor.

Function

• The carburettor governs the engine speed via the throttle.

Air and fuel are mixed in the carburettor.

Needles

The carburettor is equipped with fixed needles to ensure the

machine always receives the correct mixture of fuel and air.

When the engine lacks power or accelerates poorly, do the

following:

• Check the air filter and replace if necessary.

• When this does not help, contact an authorised service

workshop.

Fine adjustment of the idle speed T

Adjust the idle speed using the T screw. When an adjustment

is necessary, first turn the screw clockwise until the blade

starts to rotate. Now turn the screw anti-clockwise until the

blade stops rotating. A correctly adjusted idle speed is set

when the engine accelerates without hesitation.

Rec. idle speed: 2700 rpm

!

WARNING! Never use the power cutter

without a blade guard over the cutting blade.

!

WARNING! Do not start the machine without

the cutting arm or cutting head fitted.

Otherwise the clutch could come loose and

cause personal injuries.

!

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

stops, contact your dealer/service

workshop. Do not use the machine until it

has been correctly adjusted or repaired.