English - 23

Maintenance

Used correctly, the machine is an extremely low-main-

tenance and reliable.

This section covers the general maintenance items

that need attention on a periodic basis.

There are three main mechanical items to check:

1. Grinding Heads.

2. Planetary drive system.

3. Planetary seal.

Grinding heads

There are 2 different grinding head options:

11. Conventional / Demolition heads—designed for

heavy duty preparation grinding where an extremely

robust system is required.

2. Spring steel head system—designed more for fi nish-

ing or lighter grinding applications.

CONVENTIONAL/DEMOLITION HEADS

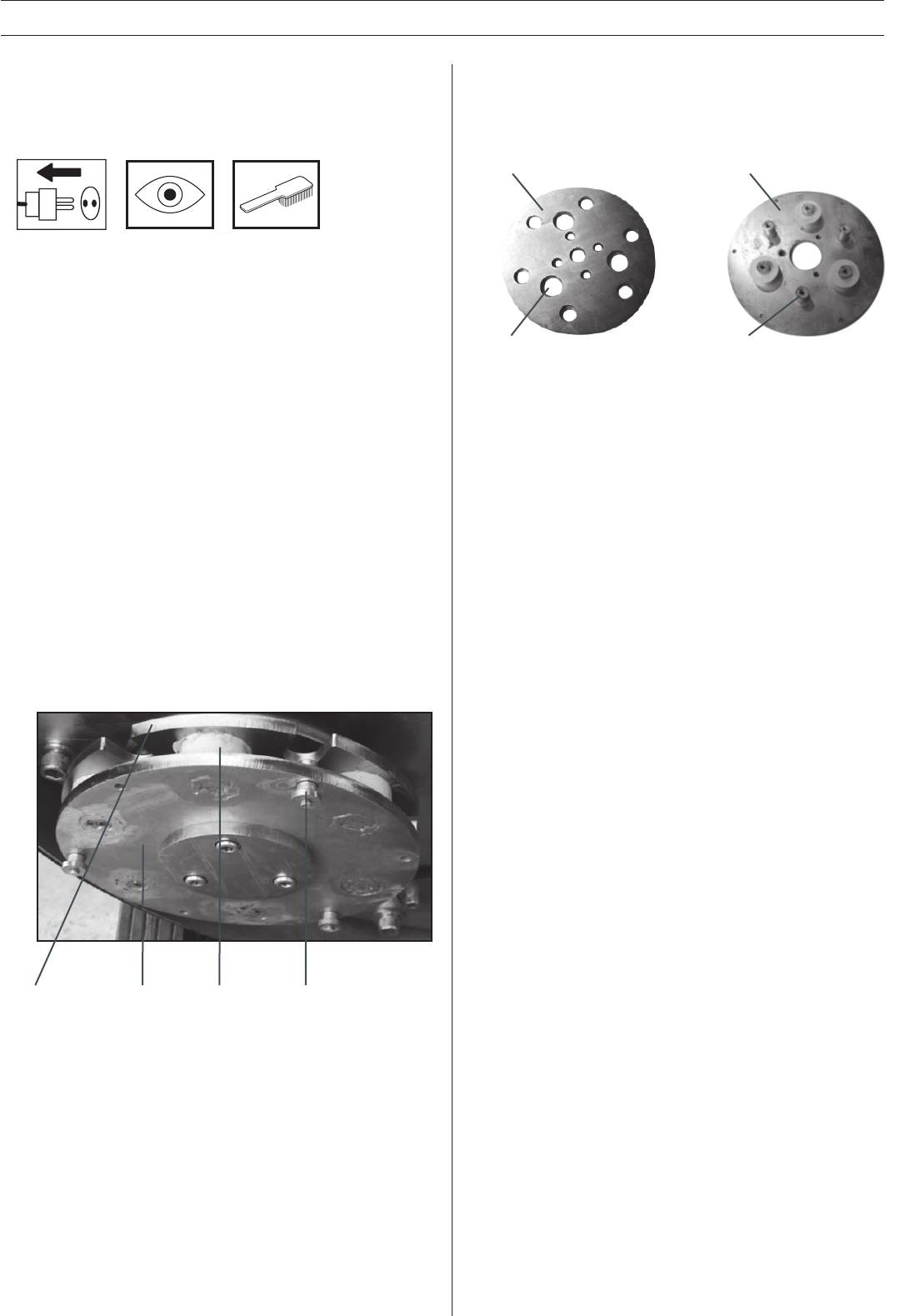

The below diagram illustrates the main parts compris-

ing this type of grinding head.

1. Head mate

2. Head plate

3. Head lock

4. Head spring

The interrelation between the above four components

enables a dynamic system which is both robust and

fl exible.

The head pins are fi xed to the head plate giving rigid-

ity and stability. The head mate is situated above the

head plate and is held in place by a series of holes

– head pin holes.

1. Head mate 1. Head plate

2. Head pin hole 2. Head pins

Between the head plate and head mate are 3 white

silicone springs which give shock absorption and fl ex-

ibility in the system.

The head pins are able to move within the head pin

holes, creating a shock absorber type system similar to

that in most motor vehicles.

Over an extended period of time, the head pin holes

wear open. Along with this, the head pins wear and

reduce in diameter. This combined wearing of the two

creates excessive movement or “slop” within the grind-

ing heads. This “slop” will eventually cause vibration

whilst the machine is operating.

Routine checks for slop in the grinding heads are

recommended. Life expectancy for grinding heads can

vary between 6 and 12 months depending on amount

of usage.

Replacement heads are available and simply bolt into

place when the old ones are removed

Maintenance

2.1. 4. 3.

2.

1.

2.

1.