635043

PAGE2OF2

ADJUSTMENT

THE AROĆSTOP VALVE MUST BE PROPERLY ADJUSTED AND

TESTED. THE INSTALLATION SHOULD BE TESTED REGULARLY

AND ADJUSTED WHEN A CHANGE IN OPERATING CONDITIONS

OCCURS. ALL ADJUSTMENTS MUST BE MADE HOLDING THE

HOSE END OF THE AROĆSTOP VALVE IN A FIXED POSITION

WHILE TURNING THE SLEEVE.

1. Turn A" sleeve clockwise tothe maximum inward position. See arĆ

row on sleeve of AROĆSTOP valve.

2. Supply AROĆSTOP valve with desired inlet operating pressure.

3. Depress C" reset button on the AROĆSTOP valve to start the

pump. Open the pump outlet to the desired flow condition.

4. Turn A" sleeve counterclockwise slowly until the pump stops.

5. Turn A" sleeve clockwise one quarter turn and tighten B" locking

nut against body.

6. To restart pump, depress the C" reset button and hold it in for

approx. 3 seconds or untilpump primes. If the pumpdoes not reset

and run, repeat step (5).If pump operates, continue onto TestSecĆ

tion.

TEST:

7. To test installation, with the pump operating, remove the pump (or

siphon tube) fromthe material supply. If thepump shutsoff, the unit

is set properly.

8. If the pump continues to turn, resubmerge the pump (or siphon

tube) in the material supply. Loosen theB" locking nut andturn the

A" sleeve counterclockwise approx. one quarter turn, tighten B"

locking nut, and repeat step (7).

RESTART:

9. To restart: Remedy the cause of the shutdown. If the air supply is

shutĆoff, turn the air back on.

10. Depress the C" reset button and hold it in approx. 3 seconds.

TROUBLE SHOOTING

AROĆSTOP valve does not close when it should.

• Improper adjustment. Readjust and test.

• Change has occurred in operating conditions (i.e. decrease in supĆ

ply pressure). Readjust and test.

AROĆSTOP valve closes for no apparent reason.

• Change has occurred in operating conditions (i.e. increase in supĆ

ply pressure). Readjust and test.

• Material supply has been interrupted. Insure constant material supply.

• Air supply turned on too quickly. Depress reset button.

Pump continues to cycle after AROĆSTOP valve closes.

• Foreign matter on sealing surface of AROĆSTOP valve. DisasĆ

semble and clean valve as described in Service Section.

NOTE: Very slow cycling may occur even after AROĆSTOP valve

closes. This is normal.

AROĆSTOP valve does not start when reset button is depressed.

• Improper adjustment. Readjust and test.

WARNING Always disconnect and relieveair pressure from the AROĆSTOP valve before removing itfrom the system forservicing.

SERVICE INSTRUCTIONS

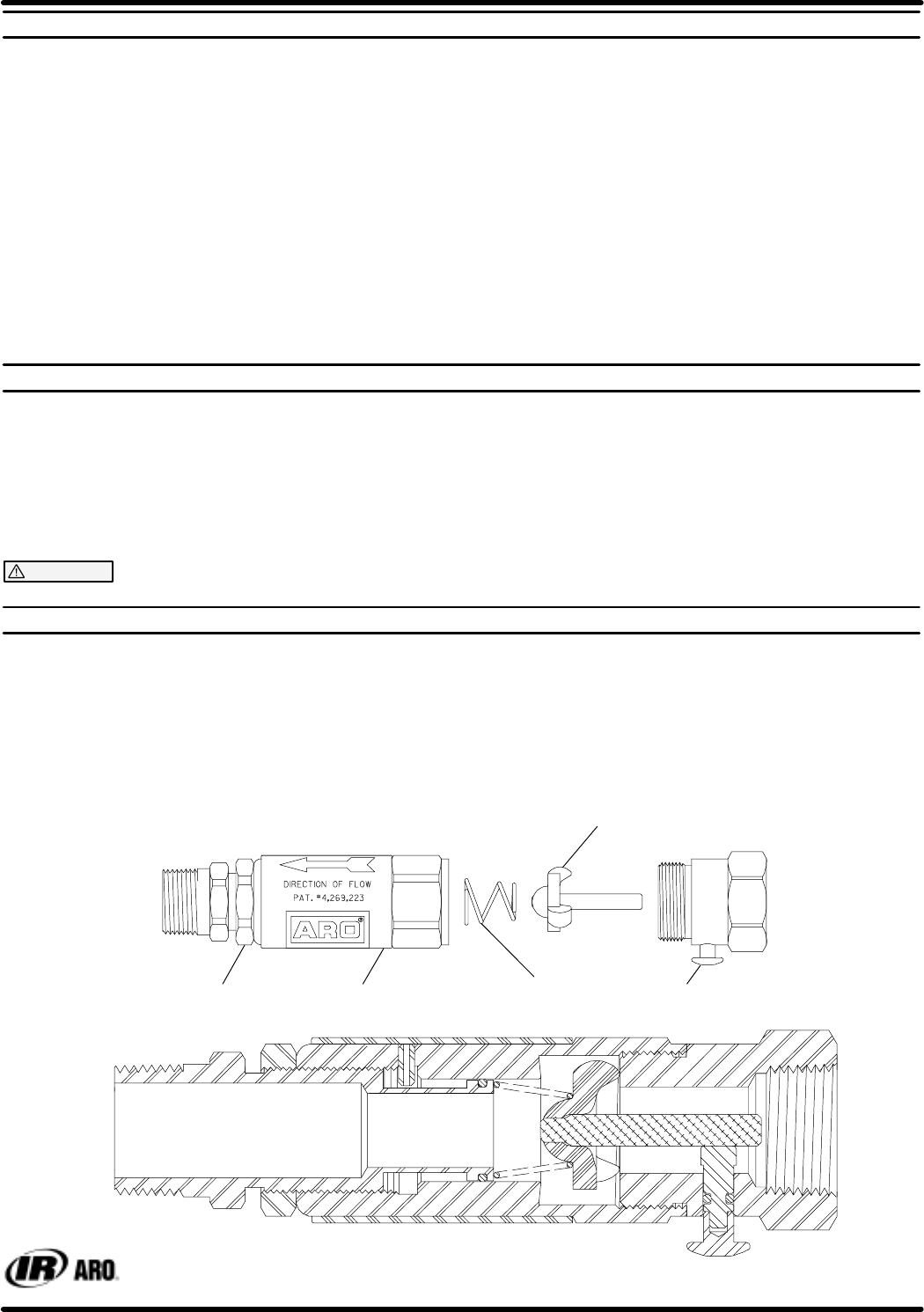

DISASSEMBLY:

1. Unscrew therear adapterassembly fromthe sleeveassembly. This

allows accessibility to the 22836 valve assembly and the 22098

spring.

2. Clean all parts andinspect for damage or wear. Replace the 22836

valve assembly or 22098 spring if necessary.

ASSEMBLY:

1. Reassemble the 22836 valve assembly and the 22098 spring as

shown in the view.

2. Apply thread locking compound to the threads of the rear adapter

assembly and tighten to the sleeve assembly using 30 Ć 40 ft lb

(40.7 Ć 54.2 Nm) torque.

NOTE: Parts other than 22836 valve assembly and 22098 spring,

are not accessible for service and should not be disassembled.

22836

22098

PN 103998

B

A

C