MOTOR SECTION

DISASSEMBLY

Remove motor assembly from housing as outlined on page 6.

Remove retaining nut (33694). Grasp cylinder in one hand and

tap threaded end of rotor with a soft face hammer; motor will come

apart.

ASSEMBLY

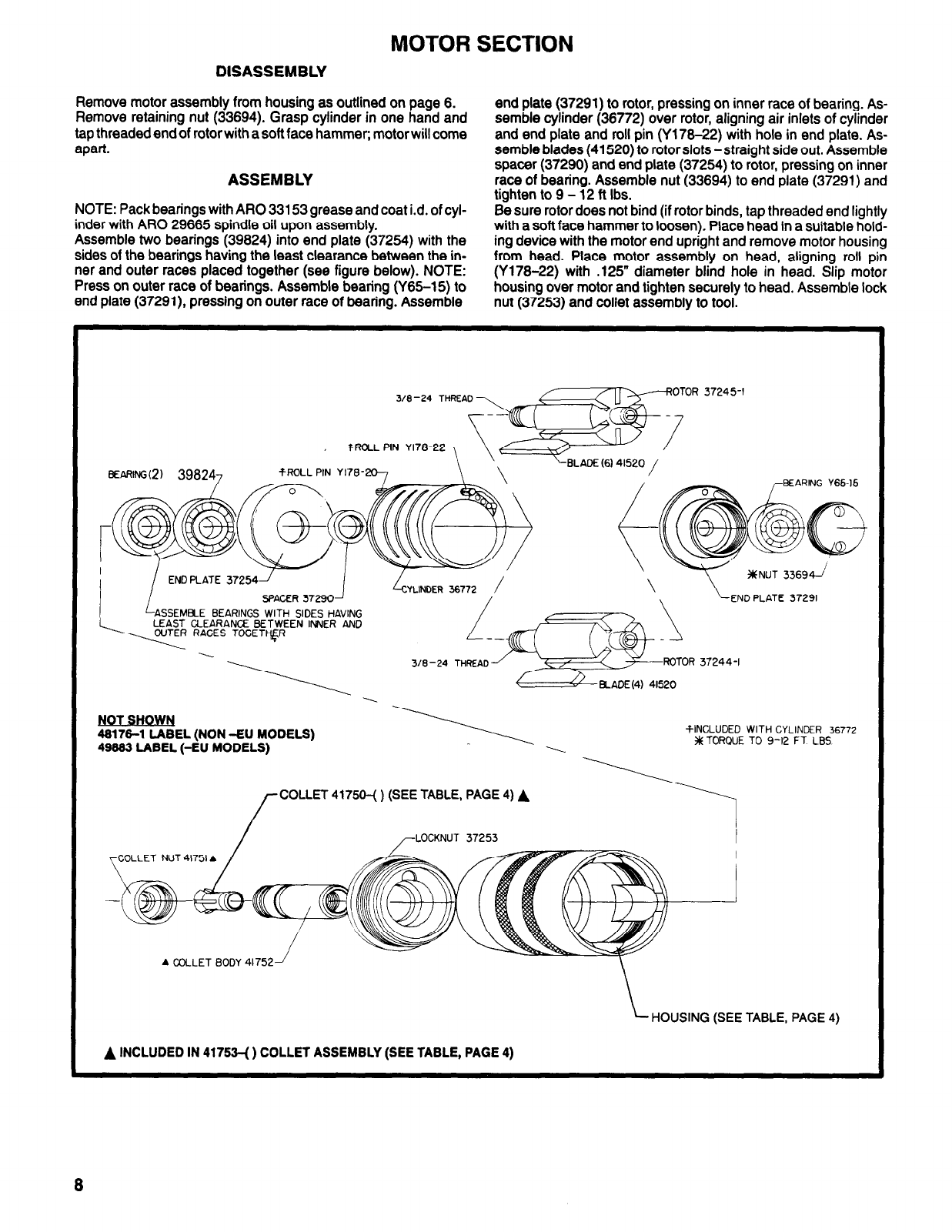

NOTE: Pack bearings with ARO 33153 grease and coat i.d. of cyl-

inder with ARO 29665 spindle oil upon assembly.

Assemble two bearings (39624) into end plate (37254) with the

sides of the bearings having the least clearance between the in-

ner and outer races placed together (see figure below). NOTE:

Press on outer race of bearings. Assemble bearing (Y65-15) to

end plate (37291), pressing on outer race of bearing. Assemble

end plate (37291) to rotor, pressing on inner race of bearing. As-

semble cylinder (36772) over rotor, aligning air inlets of cylinder

and end plate and roll pin (Y176-22) with hole in end plate. As-

semble blades (41520) to rotor slots -straight side out. Assemble

spacer (37290) and end plate (37254) to rotor, pressing on inner

race of bearing. Assemble nut (33694) to end plate (37291) and

tighten to 9 - 12 ft Ibs.

Be sure rotor does not bind (if rotor binds, tap threaded end lightly

with a soft face hammer to loosen). Place head in a suitable hold-

ing device with the motor end upright and remove motor housing

from head. Place motor assembly on head, aligning roll pin

(Y176-22) with .125” diameter blind hole in head. Slip motor

housing over motor and tighten securely to head. Assemble lock

nut (37253) and Collet assembly to tool.

TROLL

PIN Yl78-22~

3/8-24

THREA

37245-l

TROLL PIN

Yl76-

END PLATE

37254

SPACER 37290

-BLADE (6141520 /

:

EARING Y65-15

\

kND PLATE 37291

LASSEMEi..E

I\_

BEARINGS WITH SIDES HAVING

LEAST CLEARANCE BETWEEN IMUER AND

CUTER RACES TOGETqR

-\

318 -24 THREAD

i!%i%tiEL (NON -EU MODELS)

-t-INCLUDED WITH CYLINDER 36772

49999 LABEL (-EU MODELS)

$X TORQUE TO 9-12 FT LBS

/-

COLLET 41750-( ) (SEE TABLE, PAGE 4) A

I

OCKNUT 37253

COLLET NUT 41751 A

A COLLET BODY 41752

HOUSING (SEE TABLE, PAGE 4)

A INCLUDED IN 41753-( ) COLLET ASSEMBLY (SEE TABLE, PAGE 4)

8