MODEL IDENTIFICATION

The grinder models listed in the model identification table above are furnished with a collet as standard equipment and are intended for

use with mounted wheels and shall not be used with other type grinding wheels. Other size collet inserts or other collet assemblies listed

on page 10 can be furnished with the above listed models.

OPERATION

Safe and efficient operation of your ARO grinder can best be attained by observing proper operating, inspection and maintenance proce-

dures. Allow only competent and qualified people to operate grinder and subject each grinder to a regular inspection and maintenance

procedure. The qualified grinder operator must be carefully instructed in the safe operation and use of the grinder, including a study of the

manufacturer’s literature. The grinder operator should have a good attitude regarding safety.

Operator Safety Equipment. The grinder operator shall wear safe-

ty goggles or face shield at all times the grinder is turned on. Other

protective clothing shall be worn if necessary for spark deflection.

Respirators shall be used in poorly ventilated areas. Adjacent per-

sonnel shall be protected from grinding sparks and wheel frag-

ments by protective barriers.

Starting and Stopping. Before starting a grinder, the operator shall

make sure that no one is in the unguarded plane of wheel rotation.

Upon mounting a new wheel, grinder shall be run at operating

speed with the safety guard in place or in a protected enclosure for

at least one minute before applying the wheel to the work. Check

speed and balance of wheel.

Before a grinder is put down, the throttle shall be released and the

wheel shall come to a stop. Tool rests, hangers or balancers are

recommended.

Use only wheels with adequate speed ratings. The maximum op-

erating speed marked on the wheel, blotters or packaging, shall

equal or exceed the rated speed stamped on the grinder.

At each wheel change, Aro recommends the free speed be

checked by competent authorized personnel, using a good reli-

able tachometer, to assure that the maximum tool speed is lower

than manufacturers rated speed for the wheel to be used. A speed

check shall never be made with grinding wheel on the grinder.

Grinders shall not be operated at a speed exceeding its rated

speed.

If a wire brush should ever be used with this tool; insure the speed

rating of the brush is greater than the speed of the tool the brush is

to be used with and insure the brush conforms to applicable safety

standards. Be certain the brush is compatible with mounting of the

tool. Always use a wheel guard.

MOUNTING INSTRUCTIONS FOR MOUNTED WHEELS

The collet shall be checked to assure it to be in good condition and

properly affixed to the grinder spindle.

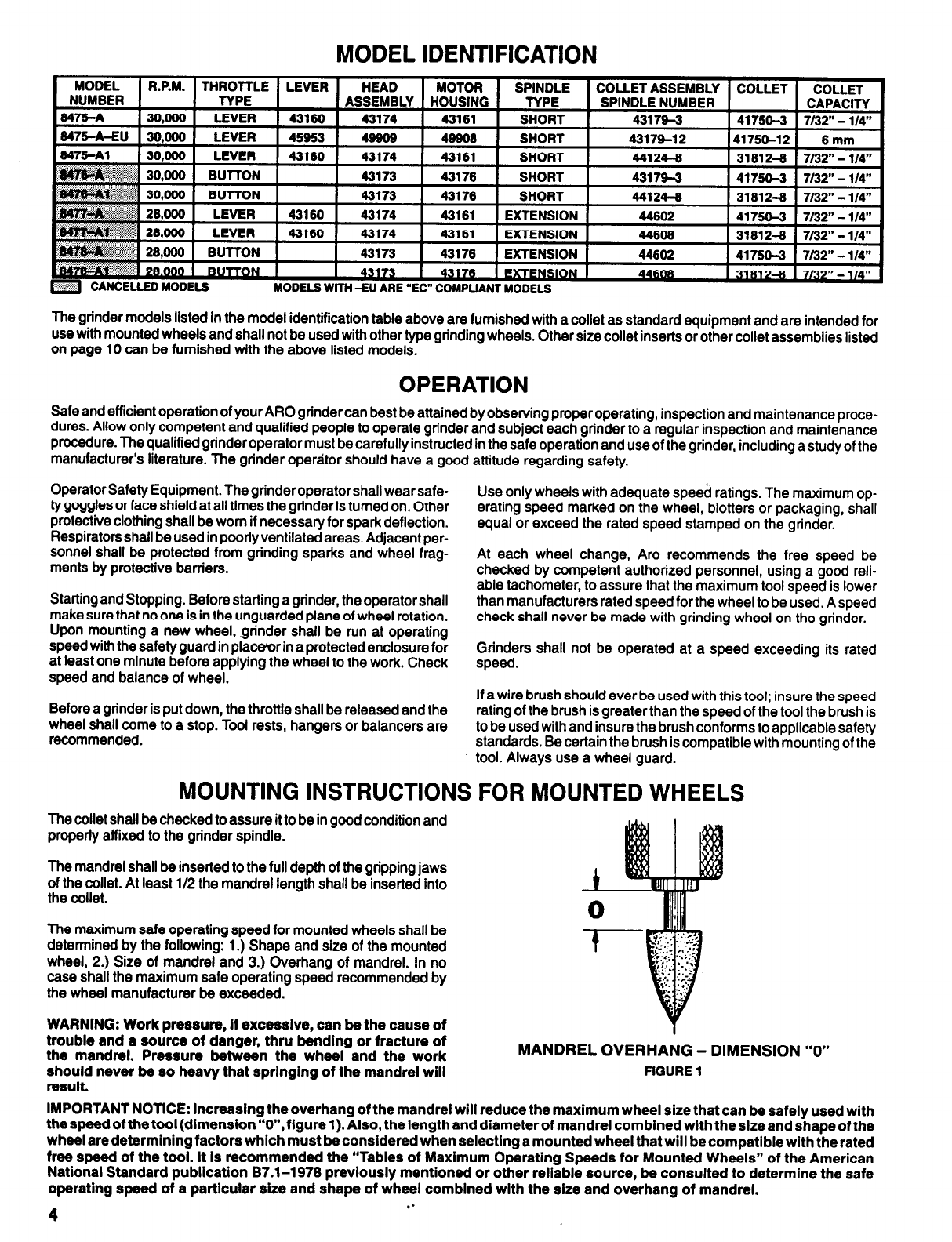

The mandrel shall be inserted to the full depth of the gripping jaws

of the Collet. At least 1/2 the mandrel length shall be inserted into

the Collet.

The maximum safe operating speed for mounted wheels shall be

determined by the following: 1.) Shape and size of the mounted

wheel, 2.) Size of mandrel and 3.) Overhang of mandrel. In no

case shall the maximum safe operating speed recommended by

the wheel manufacturer be exceeded.

WARNING: Work pressure, if excessive, can be the cause of

trouble and a source of danger, thru bending or fracture of

the mandrel. Pressure between the wheel and the work

MANDREL OVERHANG - DIMENSION “O”

should never be so heavy that springing of the mandrel will

result.

FIGURE 1

IMPORTANT NOTICE: Increasing the overhang of the mandrel will reduce the maximum wheel size that can be safely used with

the speed of the tool (dimension “O”, figure 1). Also, the length and diameter of mandrel combined with the size and shape of the

wheel are determining factors which must beconsidered when selecting a mounted wheel that will be compatible with the rated

free speed of the tool. It is recommended the “Tables of Maximum Operating Speeds for Mounted Wheels” of the American

National Standard publication B7.1-1978 previously mentioned or other reliable source, be consulted to determine the safe

operating speed of a particular size and shape of wheel combined with the size and overhang of mandrel.