QTY

1

1

5

6

1

1

1

2

1

PART

NUMBER

31092

31093

31363

36317

41795

41799

41954

42911

45474

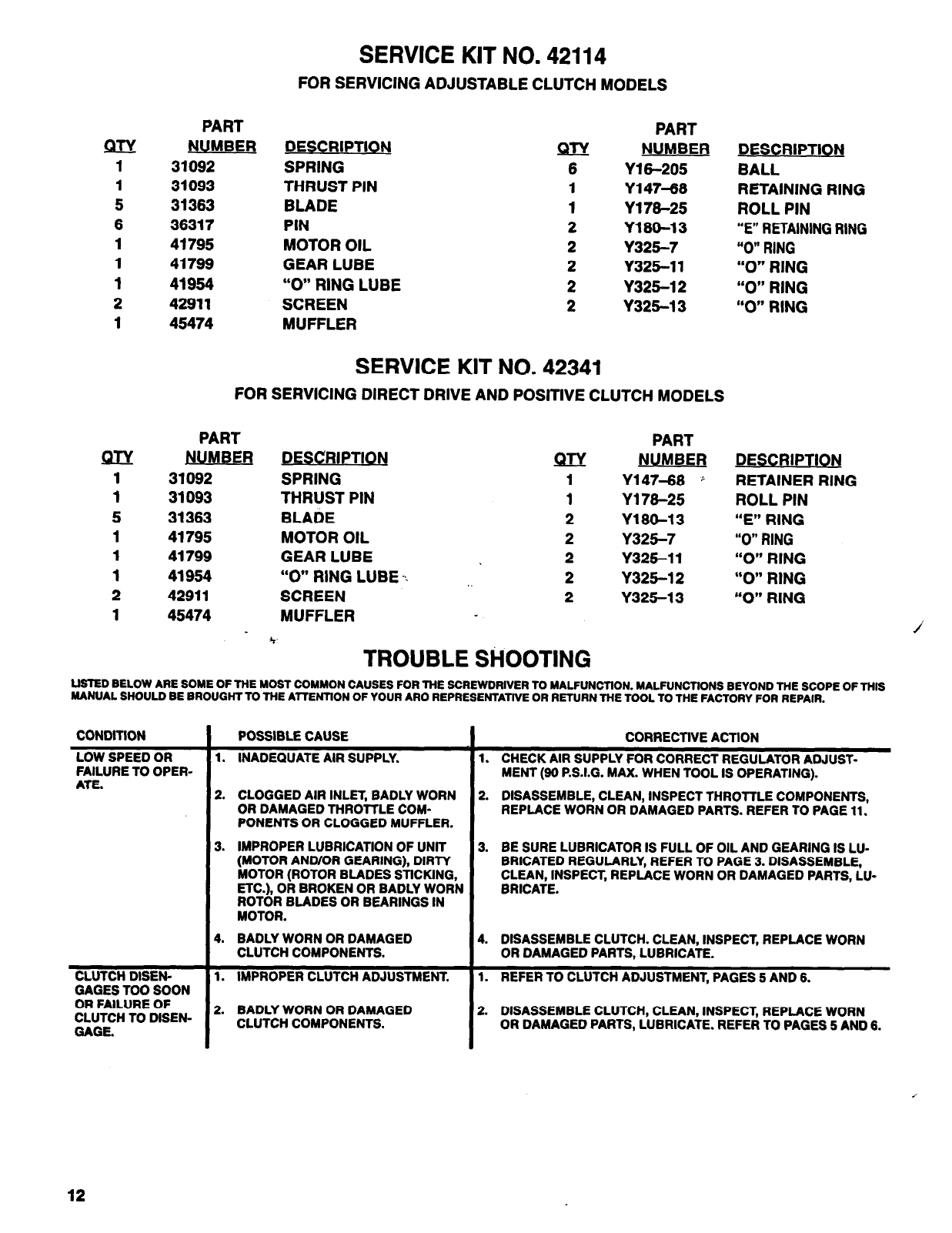

SERVICE KIT NO. 42114

FOR SERVICING ADJUSTABLE CLUTCH MODELS

DESCRIPTION

SPRING

THRUST PIN

BLADE

PIN

MOTOR OIL

GEAR LUBE

“O” RING LUBE

SCREEN

MUFFLER

PART

QTY

NUMBER

6 Y16-205

1

Y147-68

1 Y178-25

2 Y180-13

2

Y325-7

2 Y325-11

2 Y325-12

2 Y325-13

SERVICE KIT NO. 42341

FOR SERVICING DIRECT DRIVE AND POSITIVE CLUTCH MODELS

PART PART

NUMBER

DESCRIPTION

31092 SPRING

31093 THRUST PIN

31363 BLADE

41795

MOTOR OIL

41799

GEAR LUBE

41954 “O” RING LUBE

42911 SCREEN

45474

MUFFLER

QTY

NUMBER DESCRIPTION

1 Y147-68 RETAINER RING

1 Y178-25 ROLL PIN

2

Y180-13

“E” RING

2 Y325-7 “O” RING

2 Y325-11 “0” RING

2 Y325-12 “0” RING

2

Y325-13 “0” RING

TROUBLE SHOOTING

DESCRIPTION

BALL

RETAINING RING

ROLL PIN

“E” RETAINING RING

“O” RING

“0” RING

“0” RING

“0” RING

LlSTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE SCREWDRIVER TO MALFUNCTION. MALFUNCTlONS BEYOND THE SCOPE OF THIS

MANUAL SHOULD BE BROUGHTTO THE ATTENTlON OF YOUR ARO REPRESENTATlVE OR RETURN THE TOOL TO THE FACTORY FOR REPAIR.

CONDITION

LOW SPEED OR

FAILURE TO OPER-

ATE.

CLUTCH DISEN-

GAGES TOO SOON

OR FAILURE OF

CLUTCH TO DISEN-

GAGE.

POSSIBLE CAUSE

I. INADEQUATE AIR SUPPLY.

2. CLOGGED AIR INLET, BADLY WORN

OR DAMAGED THROTTLE COM-

PONENTS OR CLOGGED MUFFLER.

2.

DISASSEMBLE, CLEAN, INSPECT THROTTLE COMPONENTS,

REPLACE WORN OR DAMAGED PARTS. REFER TO PAGE 11.

3. IMPROPER LUBRICATION OF UNIT

(MOTOR AND/OR GEARING), DIRTY

MOTOR (ROTOR BLADES STICKING,

ETC.), OR BROKEN OR BADLY WORN

ROTOR BLADES OR BEARINGS IN

MOTOR.

3.

BE SURE LUBRICATOR IS FULL OF OIL AND GEARING IS LU-

BRICATED REGULARLY, REFER TO PAGE 3. DISASSEMBLE,

CLEAN, INSPECT, REPLACE WORN OR DAMAGED PARTS, LU-

BRICATE.

4. BADLY WORN OR DAMAGED

4.

DISASSEMBLE CLUTCH. CLEAN, INSPECT, REPLACE WORN

CLUTCH COMPONENTS.

OR DAMAGED PARTS, LUBRICATE.

1. IMPROPER CLUTCH ADJUSTMENT.

1.

REFER TO CLUTCH ADJUSTMENT, PAGES 5 AND 6.

2. BADLY WORN OR DAMAGED 2.

CLUTCH COMPONENTS.

DISASSEMBLE CLUTCH, CLEAN, INSPECT, REPLACE WORN

OR DAMAGED PARTS, LUBRICATE. REFER TO PAGES 6 AND 6.

CORRECTIVE ACTION

I.

CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUST-

MENT (90 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

12