1

3

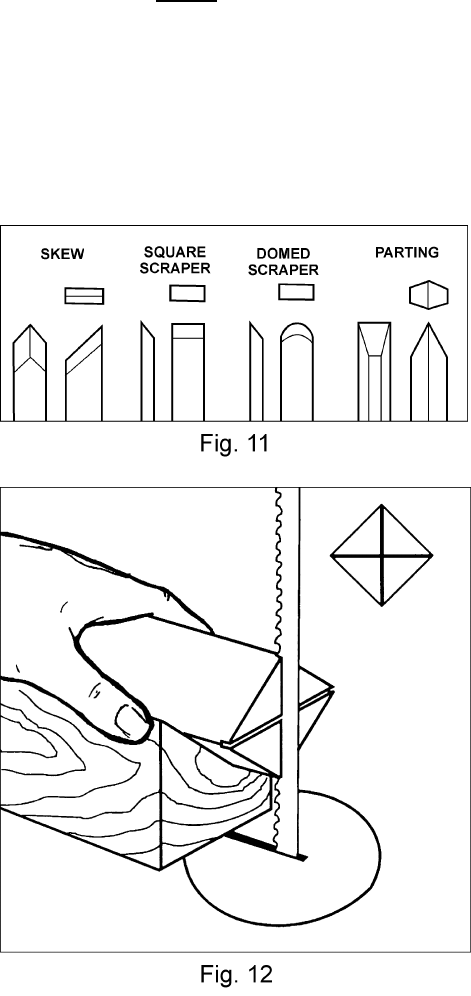

Lathe Tools (continued)

Skew — used to make vees, beads, etc., see

Figure 11.

Square Scraper — used for diameter scraping

and featureless scraping, etc, see Figure 11.

Large Domed Scraper — used to reduce ridges

on the interior of bowls, round edges of bowls,

etc, see Figure 11.

Parting Tool — used to cut directly into the

material, or to make a cut off. Also used for

scraping and to set diameters, see Figure 11.

For safety and best performance, keep tools

sharp. If a tool stops cutting, or requires

excessive pressure to make a cut, it needs to be

sharpened. A number of brand name sharpening

jigs and fixtures are available, however, a

woodturner should learn to sharpen tools

freehand.

Mounting Workpiece Between Centers

Spindle turning takes place between the centers

of the lathe. It requires a spur center in the

headstock and a live center in the tailstock.

1. With a ruler locate and mark the center on

each end by going corner to corner, see

Figure 12. Accuracy is not critical on full

rounds but extremely important on stock

where square sections are to remain. Put a

dimple in each end of the stock with an awl

or nail.

2. Extremely hard woods may require kerfs cut

into the spur drive end of stock, see Figure

12. You may need to drive the spur center

into the stock with a wood mallet. Note:

Never drive stock onto spur while it is

mounted in the lathe spindle.

3. Install workpiece by inserting the attached

spur center into the spindle taper on the

headstock.

4. Bring tailstock into position, lock it to the

bed, and advance quill with the handwheel

in order to seat the live center into the

workpiece. Lock the quill in place. Make

sure the live center point is centered on your

mark.

5. Move tool rest into position. It should be

parallel to workpiece, approximately at the

centerline, and approximately 1/8" from the

closest part of the workpiece. Lock tool rest

body and tool rest in place.

6. Rotate workpiece by hand to check for

proper clearance from tool rest. Note: You

may want to trim off the corners of a square

workpiece to make turning a little easier.

7. Start lathe at lowest

speed and bring it up to

the appropriate RPM for the size of stock,

see Figure 6 page 11.

The position of the tool rest can be varied to suit

the work and operator. After you become

experienced with setting tool rest changing the

position will become second nature for the

workpiece and comfort of the user.