8

7.0 Unpacking

Open shipping container, and any secondary

boxes. Check for shipping damage; report any

damage immediately to your distributor and

shipping agent. Do not discard any shipping

material until the Cold Saw is assembled and

running properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor. Read the instruction manual thoroughly

for assembly, maintenance and safety instructions.

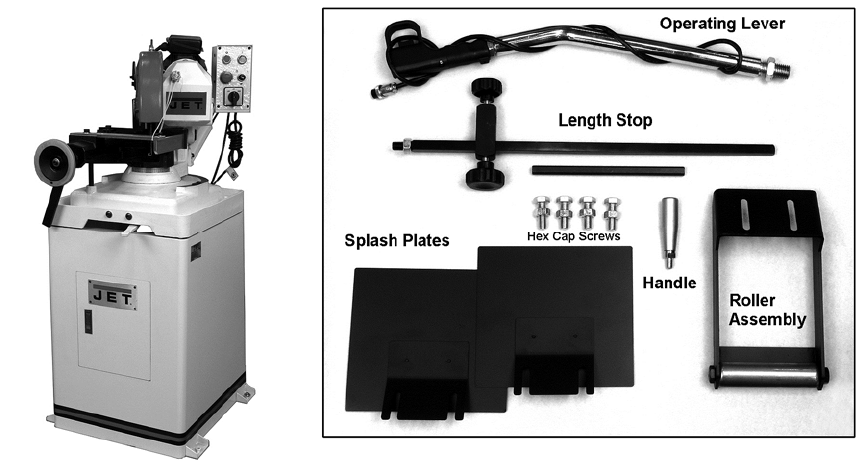

7.1 Contents of shipping container

1 Cold Saw

1 Operating Lever

1 Work Stop Assembly

4 Hex Cap Screws with Nuts

1 Handle

1 Roller Assembly

2 Splash Plates

1 Coolant Tank w/ Pump (inside base)

1 Operating Instructions and Parts Manual

(not shown)

1 Warranty Card (not shown)

Figure 2

8.0 Installation and assembly

Tools required for assembly (not provided):

6mm hex key (Allen wrench)

12mm and 19mm open-end wrenches

Remove all packing material from around the

machine. Remove screws holding the saw to the

skid. Lift the machine off the skid using straps

around the cast iron portions of the head (keep

straps away from blade, levers, etc.).

The location should have sufficient lighting to

prevent shadows around the work area. Leave

enough room on all sides of the machine for

movement of stock and for general maintenance

work.

The base of the machine must be anchored to the

floor by two lag bolts or studs properly anchored

into concrete.

After positioning the machine, remove any cords

that were used to secure the head in lowered

position during shipping.

Exposed metal surfaces have been coated with a

rust-protectant from the factory. Remove this using

a soft cloth dampened with a good

cleaner/degreaser. Do not use gasoline, paint

thinner, acetone, or other highly flammable

substances, and avoid using an abrasive pad as it

may scratch metal surfaces.