10

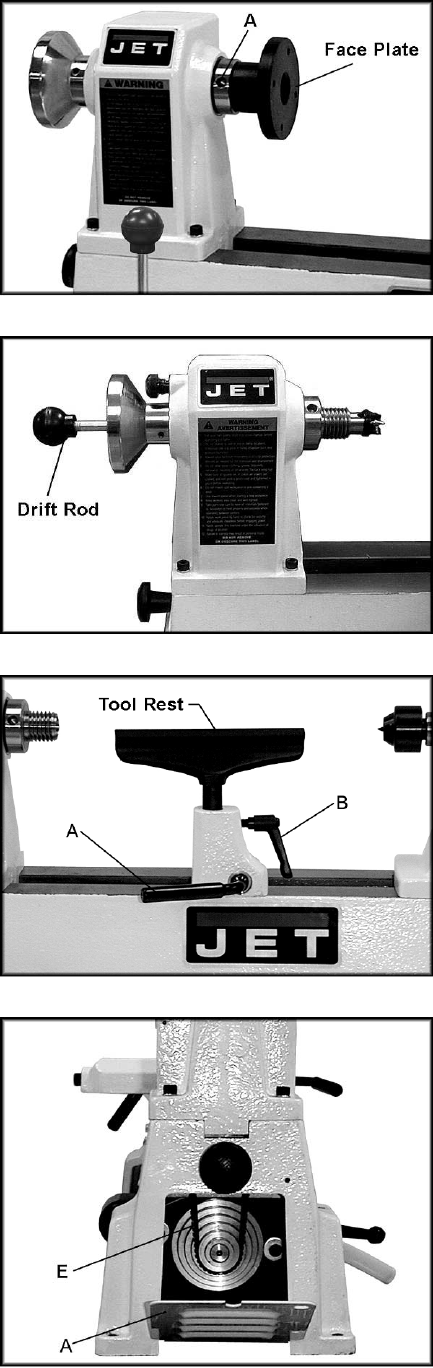

Face Plate

(Figure 6) – Screws on to the

headstock and is used in face plate turning

operations. Mount your workpiece onto the

faceplate with brass screws (not provided).

Make sure the screws are not so long that they

will enter the area of the workpiece where the

material is to be removed.

To remove the face plate from the spindle, place

the drift rod into hole (A, Figure 6) and let the

drift rod contact the bed of the lathe for

leverage. Then unscrew the face plate.

Drift Rod

(Figure 7) – Slides into the

headstock to tap the spur center free. Stored in

the hole in the base below the headstock (JML-

1014I) or in the tool caddy (JWL-1220).

NOTE: Always hold on to the spur center while

tapping it free, to prevent it from falling.

Tool Rest

(Figure 8) – Attaches to the bed.

Used to steady the cutting tool during spindle

turning or face plate operations.

Adjusting the Tool Rest

Position the tool rest (Figure 8) as close to the

workpiece as possible. It should be 1/8” above

the centerline of the workpiece.

Position the tool rest base on the bed by

releasing the locking rod (A, Figure 8) and

sliding base to the desired position. Tighten

locking rod to fix the position of the tool rest

base.

Adjust the height of the tool rest by loosening

the handle (B, Figure 8) and raising or lowering

tool rest.

Should adjustment of the tool rest clamping

device become necessary, turn off the machine,

reach under the bed, and adjust the clamping

nut.

NOTE: The lock handles (B, Figure 2 and B,

Figure 8 for example) are adjustable. Simply pull

up on the handle, rotate it on the pin, and then

release. Make sure the handle seats itself

properly upon the pin.

Changing Spindle Speeds

1. Disconnect the machine from the power

source (unplug).

2. Open the access doors at the left side of the

base (A, Figure 9) and at the back side of

the headstock (B, Figure 10).

3. Loosen the motor plate lock handle (C,

Figure 11). Lift up the motor plate handle (D,

Figure 11) to take tension off the belt.

Figure 6

Figure 7

Figure 8

Figure 9