11

Conveyor Belt Tracking

Belt tracking adjustment may be necessary

during the break-in period and normal operation

to compensate for belt stretching.

Abrasive belt tension must be properly adjusted

before adjusting the tracking. Adjust the belt

tracking while the conveyor belt is running at its

fastest speed.

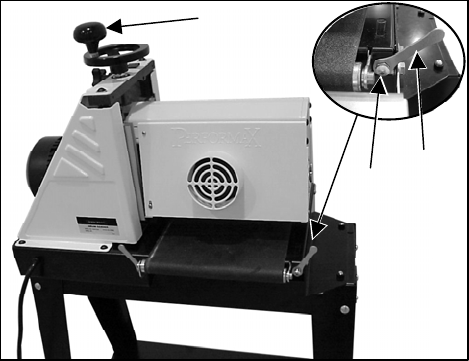

Tighten the hex nut (Figure 5, Item B) on the

side the belt is drifting towards, and loosen the

hex nut on the opposite side. Use the attached

wrenches (Figure 5, Item C) to adjust the hex

nuts.

Note: Adjustment should be made in 1/4 turns of

the hex nut. Allow time for the belt to react to the

adjustment. Do not over adjust.

Conveyor Belt Tension

Conveyor belt tension adjustment may be

necessary during the break in period to

compensate for belt stretching.

If the conveyor belt can be stopped by hand

pressure applied directly to the top of the

conveyor bed, the belt is too loose. Insufficient

belt tension will cause slippage of the conveyor

belt on the drive roller during sanding

operations.

Excessive belt tension can cause tracking

problems and result in bent rollers, bent take-up

brackets and premature conveyor belt wear.

Adjust the hex nuts (Figure 5, Item B) on both

sides of the conveyor to obtain a tight, and

equally tensioned, conveyor belt. Use the

attached wrenches (Figure 5, Item C) to adjust

the hex nuts.

Drum Height Control

Drum height is controlled by the height

adjustment handle (Figure 5, Item A). Turning

the handwheel in a counterclockwise direction

lowers the drum.

Turning the height adjustment handwheel one

revolution lowers the drum approximately 1/16”.

Figure 5

A

B

C