9

Figure 4

6. Plug the planishing hammer into the power

supply.

7. With the workpiece between the hammer

and anvil (Figure 5), press the foot switch to

begin planishing.

Note: Planishing blows-per-minute can be adjusted

by turning adjustment knob (see Figure 2).

Figure 5

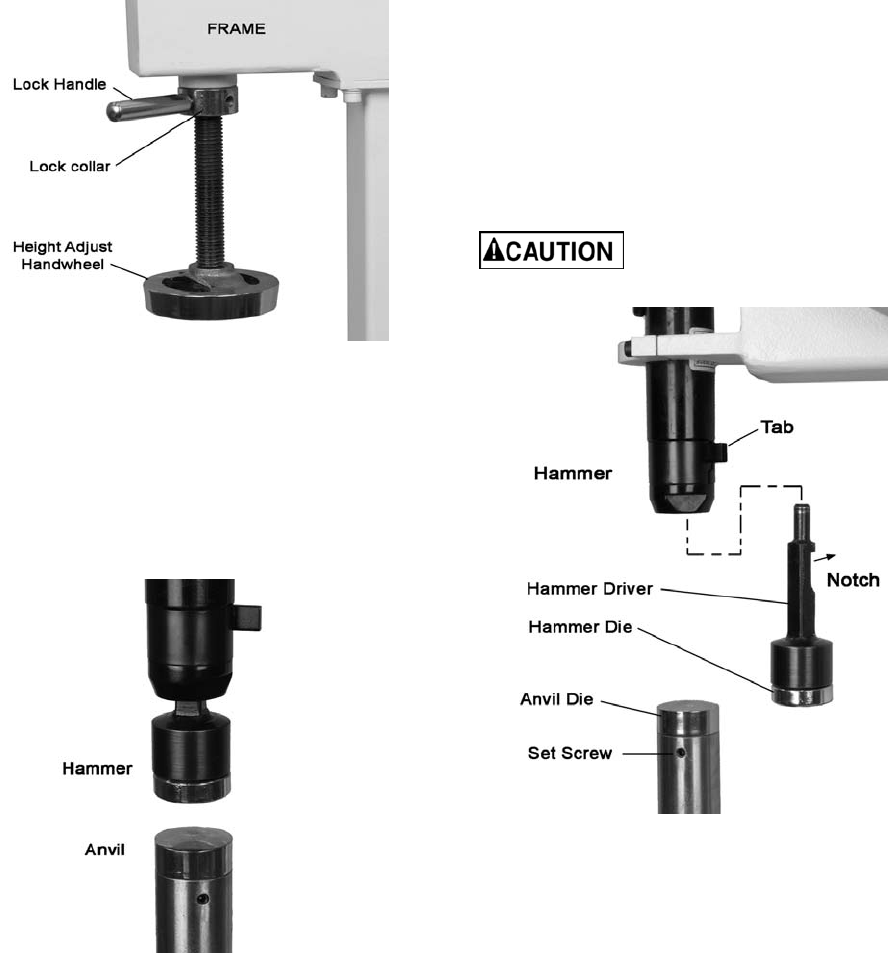

Changing Dies

Referring to Figure 6:

The PH-24T is shipped with one crowned anvil

(or lower) die, and one flat hammer (or upper)

die, which is already installed in the driver.

To remove an anvil die, loosen the set screw

and pull straight up on the anvil die. Install a new

anvil die and tighten set screw. The anvil post

accepts dies with a standard 0.79” insert end.

To remove a hammer die from the driver, use a

tool to separate them. When the die is removed,

check the condition of the o-ring inside the

driver. To reinstall a hammer die, insert it into

the driver and raise the anvil post up until it

contacts and pushes the die in.

To remove the entire driver from the hammer

barrel, push the tab on the air hammer housing

and pull down on the driver. To reinstall the

hammer drive, orient the notch toward the

general direction of the tab, and push driver

upward while still pushing back on the tab.

When the driver is properly inserted, the tab will

snap back into place.

Make sure driver and dies are

properly inserted before operating machine.

Figure 6

Maintenance

Check the following before every use:

Oil level in the lubricator; refill as needed

with ISO 32/SAE 10W non-detergent, non-

additive oil. Remove oil plug with a

screwdriver to fill.

All mounting and component hardware and

fasteners; adjust/tighten as necessary.

All air connections; replace leaking or

defective connections.

Worn or shorted wiring; replace as

necessary.

Periodically check the filter/regulator bowl for

fluids or sediment accumulation, and empty it if

needed. To remove a bowl, shut off air supply

and bleed excess air; then press the tab, rotate

bowl to the left, and pull down. Reverse

procedure to reinstall bowl. Make sure bowl is

locked in position before applying air to the

system!