Cordless Impact Wrench Operator's Manual 17

Operation

OPERATION (CONTINUED):

5. Selecting the socket matched to the bolt:

a. Be sure to use a socket which is matched to the bolt

to be tightened. Using an improper socket will not

only result in insufficient tightening but also in

damage to the socket or nut.

b. A worn or deformed hex or square-holed socket will

not give an adequate tightness for fitting to the nut or

anvil, consequently resulting in loss of tightening

torque.

c. Pay attention to wear of socket hole, and replace

before further wear has developed.

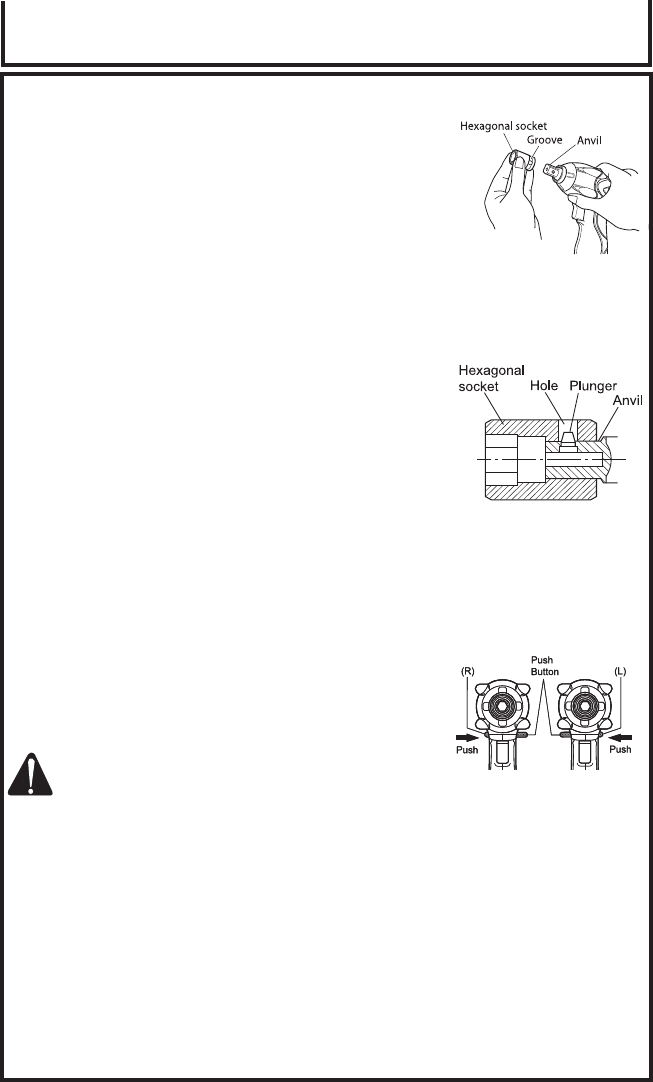

6. Installing a socket (Fig. 13, 14):

Align the plunger located in the square part of the

anvil with the hole in the hex. socket. Then push the

plunger, and mount the hex. socket on the anvil.

Check that the plunger is fully engaged in the hole.

When removing the socket, reverse the sequence.

7. Removing the socket:

Please do the opposite point on the method of installing

socket.

8. Confirm that the battery is mounted correctly.

9. Check the rotational direction:

The bit rotates clockwise (viewed from the rear side) by

pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise. (See Fig. 15). (The (L) and (R) marks

are engraved on the body.)

(Fig. 13)

(Fig. 14)

(Fig. 15)

CAUTION: THE PUSH BUTTON CAN NOT BE

SWITCHED WHILE THE IMPACT

DRIVER IS TURNING. TO SWITCH

THE PUSH BUTTON, STOP THE

IMPACT DRIVER, THEN SET THE

PUSH BUTTON.

10. Switch operation:

a. When the trigger switch is depressed, the tool rotates. When the trigger is

released, the tool stops.

b. The rotational speed can be controlled by varying the amount that the trigger

switch is pulled. Speed is low when the trigger switch is pulled slightly and

increases as the trigger switch is pulled more.

NOTE: A buzzing noise is produced when the motor is about to rotate; this is only a

noise, not a machine failure.