SCREWDRIVING

WHEN DRIVING FASTENERS:

• Always start slowly and gradually increase the speed of the Drill.

• Release the trigger when you feel the clutch slip.

• Always keep the driver bit straight to prevent damage to the screw.

• Hold the Drill with both hands to ensure control if the bit should stick or slip.

• To prevent wood from splitting, drill pilot holes into the wood before driving

in the screws.

DRILLING METAL

WHEN DRILLING HARD METALS:

• Apply a lubricant, such as cutting oil, to the tip of the bit.

• Start with a small hole then enlarge to the required size. Make sure the bit is

actually cutting and not spinning in the hole as this will dull the edges of the bit.

• Keep enough pressure on the bit to keep it drilling through the material.

DRILLING MASONRY

WHEN DRILLING MASONRY:

• Masonry can be brittle so be careful not to apply too much pressure and crack

the material.

• Apply enough pressure to keep the bit cutting and not spinning in the hole as this

will dull the edges of the bit.

• Bricks and similar soft materials will require less pressure, concrete will require

much more.

DRILLING WOOD

Use twist bits to drill holes in wood. Make sure the bits are sharp. Pull the bits

out of the hole frequently to clear chips from the flutes as an overburdened bit

may overheat.

HINTS FOR OPTIMUM USE

DRILLING:

• Keep the right amount of pressure in a straight line with the drill bit. Too little and

the bit will spin without cutting, too much and the motor may stall.

16

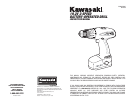

TORQUE SETTINGS

To prevent damaging the tool or driving screw too deep

into work piece, release the trigger when you feel the clutch slip.

THE CONTROL RING ADJUSTS THE LEVEL OF TORQUE:

• For light duty work, use lower settings.

• For heavy duty work, use higher settings.

PROPER SETTING FOR DRIVING SCREWS:

1. Set the ring on the lowest

setting to begin.

2. Try tightening the first screw.

If the drill drives smoothly,

proceed with the next screw.

3. If the Drill’s clutch slips,

increase the torque setting

and try again until the Drill

drives the screw without incident.

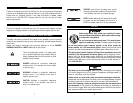

HIGH/LOW SPEED (GEAR) SHIFTING

FOR LOW SPEED SETTING:

• Slide the switch on top of the

Drill to Position 1 for high

torque applications and driv-

ing screws.

FOR HIGH SPEED SETTING:

• Slide the switch to Position 2

for light duty projects.

15

CONTROL RING

HIGH SPEEDLOW SPEED