Brushes will wear with use and should be inspected periodically by qualified

personnel.

Regularly clean the ventilation slots in your tool using only a soft brush or dry cloth.

Never open the Rotary Tool case. Do not attempt to repair the Rotary Tool yourself.

Opening the case will void your warranty.

AACCCCEESSSSOORRIIEESS

UUssee oonnllyy aacccceessssoorriieess tthhaatt aarree rreeccoommmmeennddeedd bbyy tthhee mmaannuuffaaccttuurreerr ffoorr yyoouurr mmooddeell..

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

AAllwwaayyss aattttaacchh ggrroouunndde

edd ((33--pprroonngg)) eexxtteennssiioonn ccoorrddss ttoo ggrroouunnddeedd ((33--hhoollee)) oouuttlleettss..

TThhiiss pprroodduucctt sshhoouulldd bbee ggrroouunnddeedd.. IInn tthhee eev

veenntt ooff aann eelleeccttrriiccaall sshhoorrtt cciirrccuuiitt,,

ggrroouunnddiinngg rreedduucceess tthhee rriisskk ooff eelleeccttrriicc sshhoocckk bbyy pprroovviiddiinngg aann eessc

caappee wwiirree ffoorr tthhee

eelleeccttrriicc ccuurrrreenntt..

This product is equipped with a cord having a grounding wire with

an appropriate grounding plug. The plug must be plugged into an outlet that is prop-

erly installed and grounded in accordance with all local codes and ordinances.

IIff yyoouu mmuusstt uussee aann eexxtteennssiioonn ccoorrdd,, bbee ssuurree tthhaatt tthhee ggaauuggee iiss l

laarrggee eennoouugghh ttoo ccaarrrryy

tthhee aammoouunntt ooff ccuurrrreenntt nneecceessssaarryy ffoorr yyoouurr ppoowweerr ttooooll..

If not, your tool may

experience a loss of power, excessive voltage drop or overheating. The smaller the

gauge number, the heavier the cord (see table below).

RREECCOOMMMMEENNDDEEDD SSIIZZEESS OOFF EEXXT

TEENNSSIIOONN CCOORRDDSS 112200 VVOOLLTT AACC 6600 HHZZ TTOOOOLLSS

TTOOOOLL CCUURRRREENNTT RRAATTIINNGG CCOONNDDUUCCTTOORR SSIIZZEE IINN AA..WW..GG

AMPERE 10FT. 25FT. 50FT. 100FT.

3-6 18 18 18 18

6-8 18 18 18 16

8-10 18 18 18 14

10-12 16 16 14 14

12-16 14 12 12 -

16-20 12 12 12 -

12

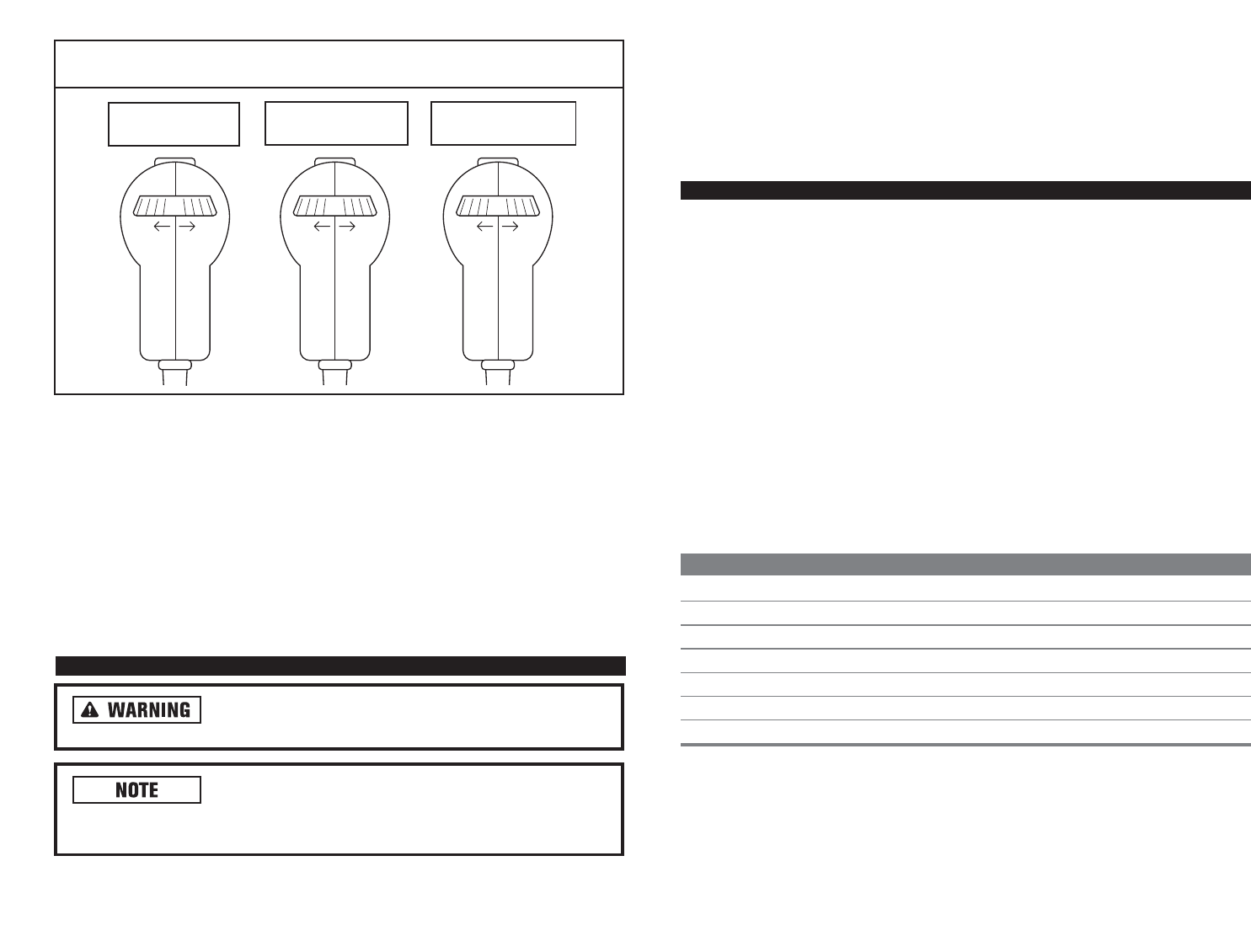

If you are doing delicate woodcarving, polishing, buffing or any use which requires

a wire brush, slow speeds of 15,000 RPM or less are best. Any material, like plas-

tic, that melts at low temperatures should also be cut at low speeds.

If you are carving, routing, shaping or cutting glass, metal or hardwoods, higher

speeds are necessary. Drilling should also be done at high speed.

Softer metals, like aluminium, copper alloys, and tin may be cut at various speeds,

depending on the type of cutting being done. A lubricant like wax should be used on

the cutter to keep the cut material from adhering to the cutter teeth.

If the tool is not performing the way you think it should, perhaps you are using the

wrong accessory. Putting pressure on the tool will not help the performance.

MMAAIINNTTEENNAANNCCEE AANNDD CCLLEEAANNIINNGG

AAllwwaayyss UUNNPPLLUUGG tthhee RRoottaarryy TTooooll ffrroomm tthhee ppoowweerr ssoouurrccee

bbeeffoorree iinnssppeeccttiinngg,, ppeerrffoorrmmiinngg aannyy mmaaiinntteennaannccee oorr c

clleeaanniinngg..

TThhiiss RRoottaarryy TTooooll iiss lluubbrriiccaatteedd bbeeffoorree iitt lleeaavveess

tthhee ffaaccttoorryy..

This lubrication should last for the life of the tool. No further

lubrication is required.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside

the casing. Never immerse any part of the tool in a liquid. Always keep the ventila-

tion openings clear.

11

S M H

Slow

8,000-12,000 RPM

Medium

20,000-25,000 RPM

High

29,000-33,000 RPM

Rotary Tool Speed Settings