In a closed system use a

,/thermal expansion tank

_r Cold Water I]Pressure Reducing

inlet Valve HValve with Bypass

Hot Water,.._

Outlet =:_ [_ _Cold Water Supply/_

H_H to Fixture SupplyMain_Water

Metal Drain-..,

Pan 1-3/4"

Depth Max.

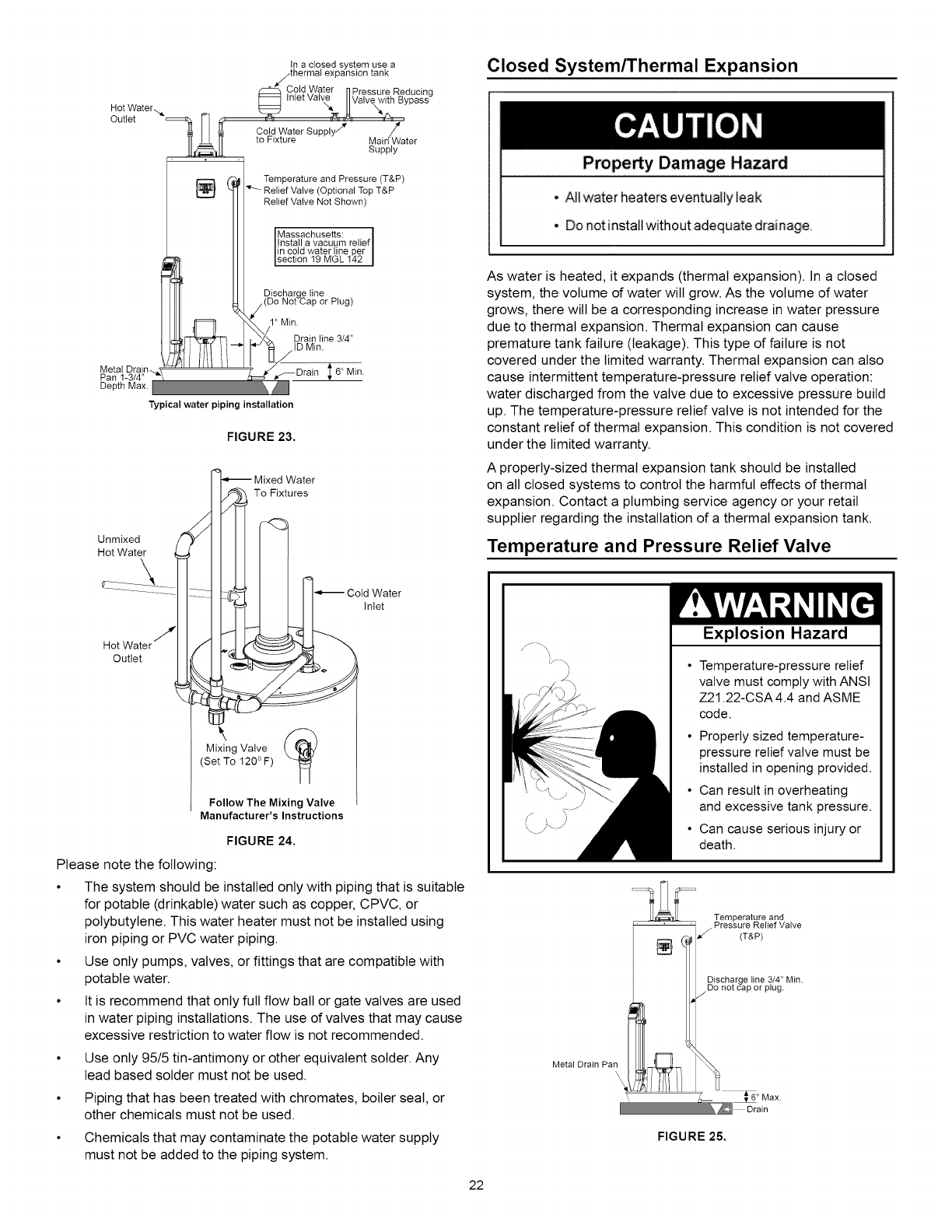

Typical water piping installation

FIGURE 23.

Unmixed

Hot Water

Hot

Outlet

_,_ Mixed Water

To Fixtures

_]_,_ Cold Water

_ Inlet

Mixing Valve

(Set To 120oF)

Follow The Mixing Valve

Manufacturer's Instructions

FIGURE 24.

Please note the following:

• The system should be installed only with piping that is suitable

for potable (drinkable) water such as copper, CPVC, or

polybutylene. This water heater must not be installed using

iron piping or PVC water piping.

• Use only pumps, valves, or fittings that are compatible with

potable water.

• It is recommend that only full flow ball or gate valves are used

in water piping installations. The use of valves that may cause

excessive restriction to water flow is not recommended.

• Use only 95/5 tin-antimony or other equivalent solder. Any

lead based solder must not be used.

• Piping that has been treated with chromates, boiler seal, or

other chemicals must not be used.

• Chemicals that may contaminate the potable water supply

must not be added to the piping system.

Closed System/Thermal Expansion

Pmpe_y Damage Hazard

• All water heaters eventually leak

• Do notinstallwithoutadequate drainage.

As water is heated, it expands (thermal expansion). In a closed

system, the volume of water will grow. As the volume of water

grows, there will be a corresponding increase in water pressure

due to thermal expansion. Thermal expansion can cause

premature tank failure (leakage). This type of failure is not

covered under the limited warranty. Thermal expansion can also

cause intermittent temperature-pressure relief valve operation:

water discharged from the valve due to excessive pressure build

up. The temperature-pressure relief valve is not intended for the

constant relief of thermal expansion. This condition is not covered

under the limited warranty.

A properly-sized thermal expansion tank should be installed

on all closed systems to control the harmful effects of thermal

expansion. Contact a plumbing service agency or your retail

supplier regarding the installation of a thermal expansion tank.

Temperature and Pressure Relief Valve

Explosion Hazard

Temperature-pressure relief

valve must comply with ANSI

Z21.22-CSA 4.4 and ASME

code.

• Properly sized temperature-

pressure relief valve must be

installed in opening provided.

• Can result in overheating

and excessive tank pressure.

• Can cause serious injury or

death.

Temperature and

Pressure Relief Valve

(T&P)

Discharge line 3/4" Min.

Do not cap or plug.

Metal Drain Pan

FIGURE 25.

22