E-3

TROUBLESHOOTING

E-3

RANGER® 305D (CE)

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

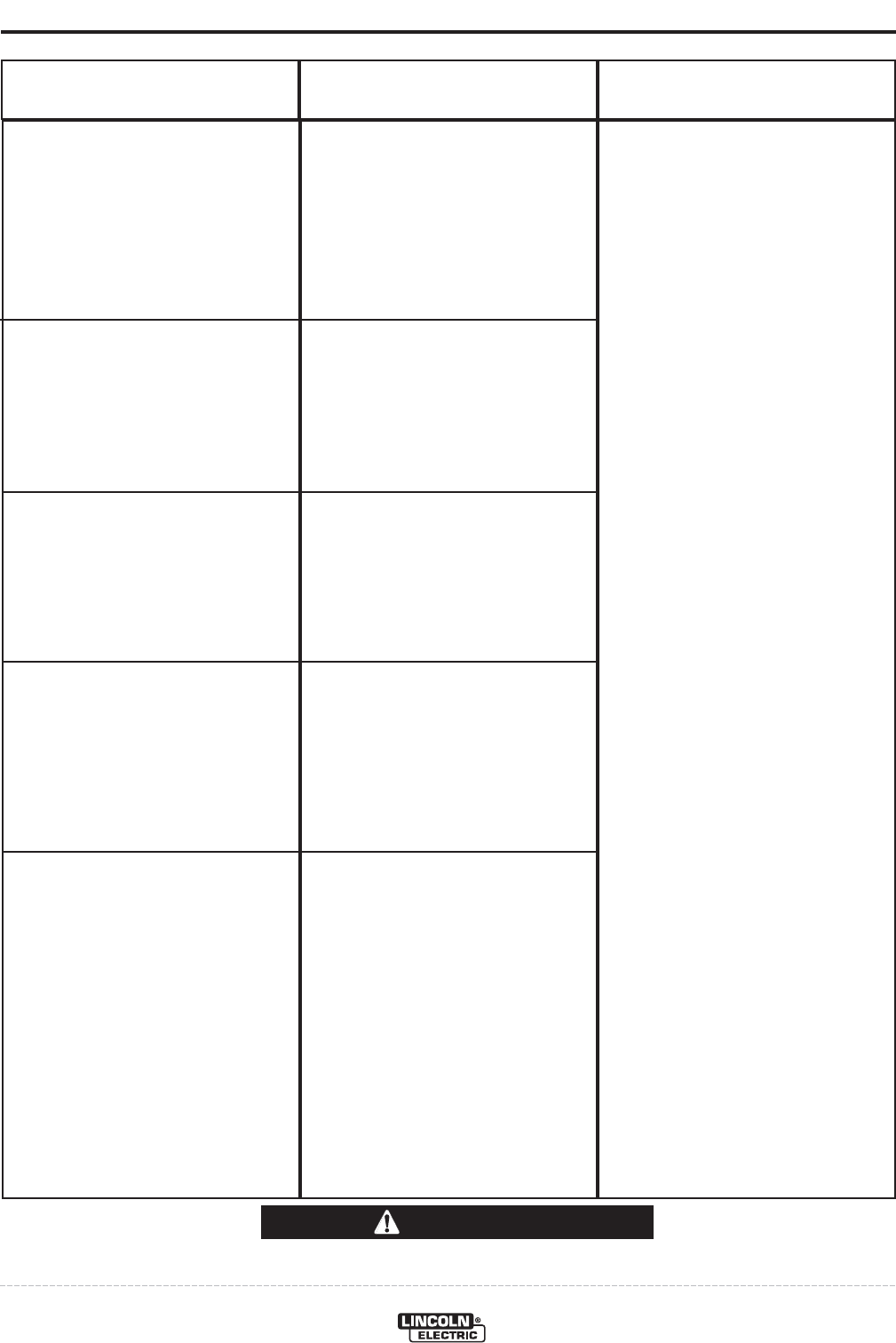

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Engine shuts down while under a

load.

Engine runs rough.

Battery does not stay charged.

Engine will not idle down to low

speed.

Engine will not go to high idle when

attempting to weld.

1. High radiator coolant tempera-

ture. Reduce load if it is exceed-

ing machine rating. Add coolant

to system if low. Clean fins on

radiator if dirty. Tighten fan belt if

loose. Remove objects blocking

or close to intake openings on

both sides of base and exhaust

end (case back).

1. Dirty fuel or air filters. Inspect and

clean/replace filters as needed.

Inspect and clean/replace filters

as needed.

2. Water in fuel. If water found in

tank. Empty fuel tank and refill

then purge fuel lines.

1. Faulty battery. Replace.

2. Loose connections at battery or

alternator. Clean and tighten con-

nections.

3. Faulty engine alternator or charg-

er module. Consult authorized

Engine Service Shop.

1. Idler switch in High idle position.

Set switch to Auto.

2. External load on welder or auxil-

iary power.

Remove all external

loads.

3. Faulty PC board or idler sole-

noid.

1. Poor work lead connection to

work. Make sure work clamp is

tightly

connected to clean base

metal.

2. "Contactor" switch is in wrong

position.

Set to "Welding On" when

welding without a control cable.

Refer to Operations chapter for prop-

er use of this switch.

3. Faulty PC board. Low idle speed

set to low.

If all recommended possible areas of

misadjustment have been checked

and the problem persists, Contact

your local Lincoln Authorized

Field Service Facility.