4/6

AC/DC Submerged Arc Welding

WAVEFORM CONTROL TECHNOLOGY

®

The future of welding is here.

®

Using AC/DC

Interfacing

with Power Wave AC/DC 1000

Hard Automation

For repeatable, high-deposition, quality

welds, the Power Wave AC/DC 1000

coupled with a PLC provides a reliable

hard automation welding solution. The

Power Wave AC/DC 1000 can easily

be connected to a PLC with the

standard Ethernet/DeviceNet gateway

board (which is included in the Power

Wave AC/DC 1000). The

Ethernet/DeviceNet gateway board

also allows the system to be tracked

and monitored from a remote location,

over a network.

Power Wave

®

AC/DC 1000™ multi-arc welding is

being used for:

• Longitudinal and spiral pipe mills

• Mold rebuilding

• Structural material for bridges and offshore platforms

• Pressure vessels

• Shipbuilding

The Power Wave AC/DC 1000 is designed to be

easily paralleled for welding applications that

require higher amperage. Each Power Wave

AC/DC 1000 provides 1000 amps of AC or DC

output at 100% duty cycle and can be paralleled

to any desired capacity.

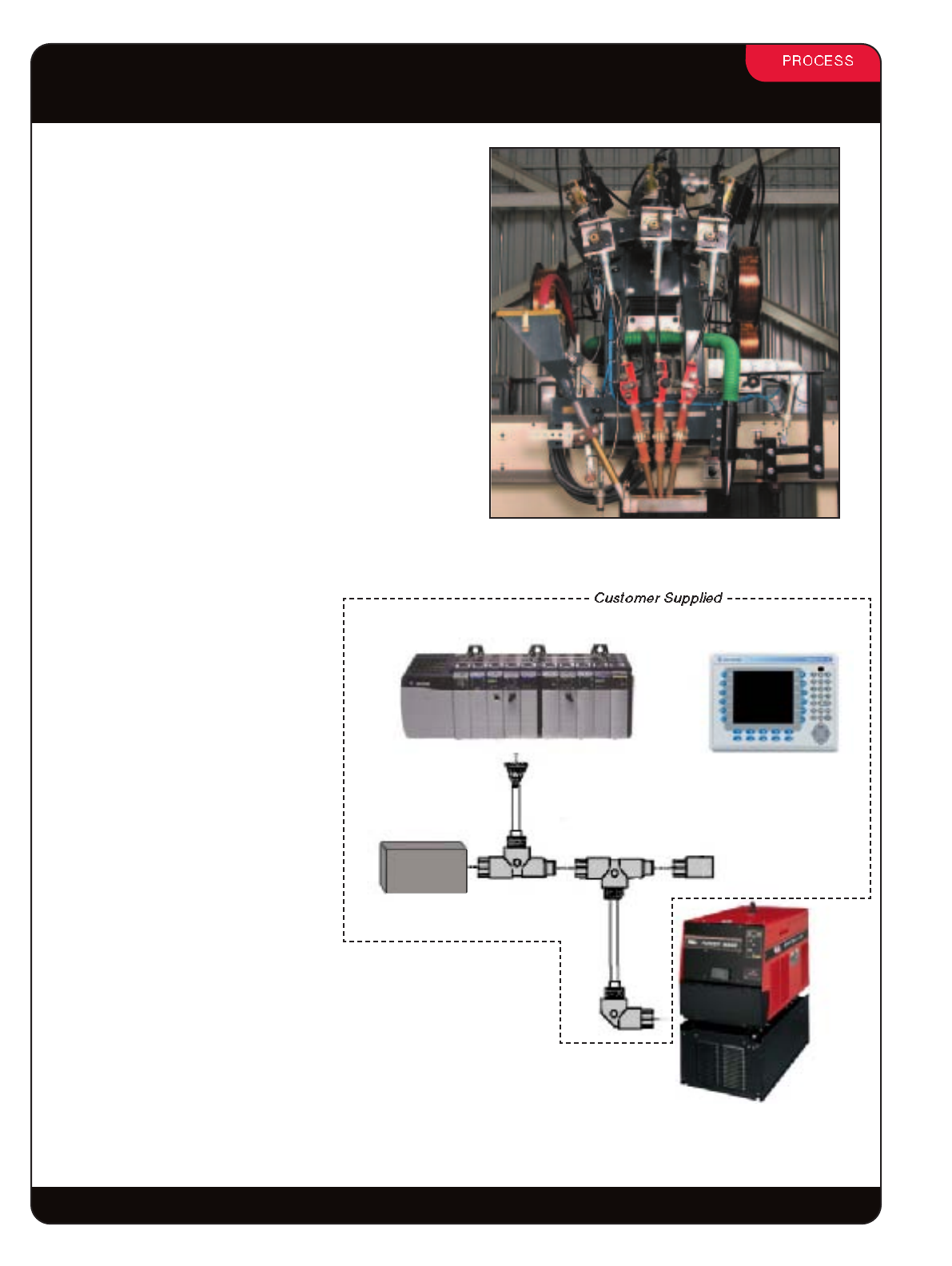

Three-Arc Power Wave AC/DC 1000 Submerged Arc

welding system controlled by a PLC

Programmable Logic Controller (PLC)

Allen-Bradley

TM

PanelView

User Interface

24 Volt Power Supply

Power Wave AC/DC 1000 with

Ethernet/DeviceNet Gateway

Typical Hard Automation Welding System Configuration

– and –