5/6

AC/DC Submerged Arc Welding

WAVEFORM CONTROL TECHNOLOGY

®

The future of welding is here.

®

Fill

Productivity

Process Current

(Amps)

Voltage

(Volts)

Travel

Speed

(IPM)

Total

Kj/in.

Wire Feed

Speed

(IPM)

Electrode

Diameter

(in.)

Deposit

Rate

(Lbs/Hr)

Total

Lbs/Hr

Area/pass

(sq. in.)

100% DC/AC 650/650 30/34 31 80.5 45/55 5/32 15/18 32.66 0.0620

109% AC

Balanced

650/650 30/34 31 80.5 54/55 5/32 17.5/18 35.59 0.0676

130% AC

25% DCEP

Balanced

650/650 30/34 31 80.5 64.5/65.7 5/32 21/21.4 42.39 0.0805

135% AC 25%

DCEP 25%

DC Offset

650/650 30/34 31 80.5 68/67 5/32 22/22 44 0.0836

Productivity

of Dual Arc SAW

Benefits

of Power Wave

®

AC/DC 1000™

Power Electronics

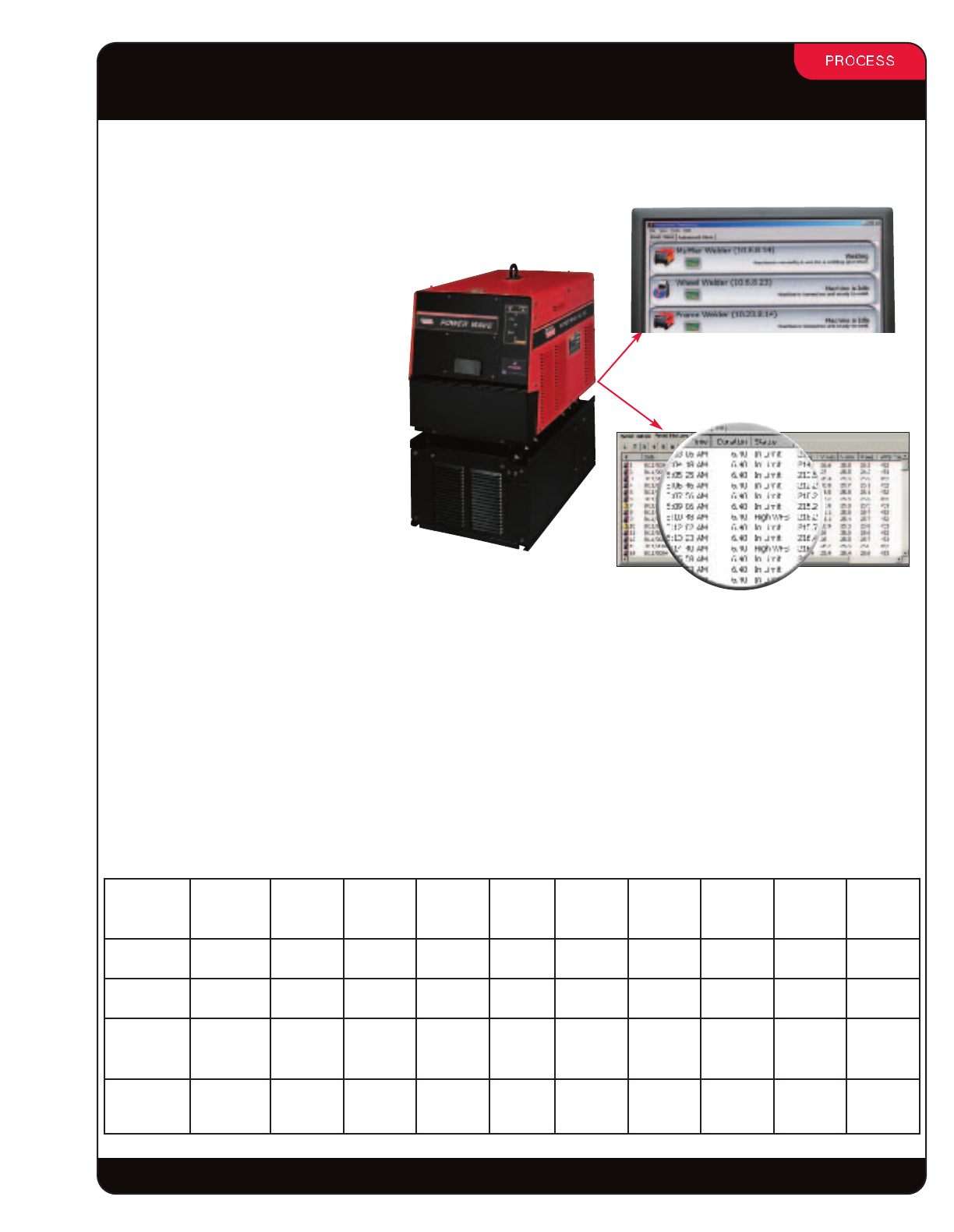

Power Wave AC/DC 1000 uses

inverter technology, not SCR or

cyclo-conversion, which limits

control options.

Control

Choice of AC frequency (from 10 Hz to

100 Hz) standard, balance of positive

and negative half-cycles, and

amplitudes.

Efficiency

Inverter power sources operate

at 87% efficiency and a power

factor of 95%.

Stability

Increased stability of phase-shifting of

multiple arcs due to the capability of

any degree of shift to create equal ratios

of magnetic push and pull.

Waveform Control

Waveform Control and infinite phase

shifting stabilize imbalanced waveforms.

The operator achieves full control of

penetration and deposition without

changing heat input levels.

Communications between ArcLink and

Ethernet enable equipment tracking via

Lincoln Electric's Production Monitoring™

software utility.

Power Wave AC/DC 1000