CAST IRON / ALUMINUM

ADVANTAGE

LINCOLN

GUIDELINES FOR

WELDING CAST

IRON

SOFTWELD

®

55 Ni (ENiFe-CI)

A versatile, all-purpose electrode for

repairing and reclaiming gray cast iron.

It is recommended for repairing heavy

sections and phosphorous bearing

castings. Welds made with this

electrode are strong and ductile.

Multi-pass welds are typically

machinable. Operational

characteristics are excellent.

SOFTWELD

®

99 Ni (ENi-CI)

A high nickel electrode specifically

recommended for applications where

machinability is important. Even

single pass welds are machinable.

It is recommended for surfacing

applications and repairing small

casting defects when the deposit

will require machining.

FERROWELD

®

(ESt)

A low cost steel electrode for repairing

cast iron. It is recommended for

repairing pits and small cracks in

castings. The deposits are not

machinable but may be finished

by grinding.

ALUMINWELD

®

43 (E4043)

An extruded electrode for both

metallic arc and carbon arc welding

aluminum plate. The dense high

strength welds can be polished

leaving practically no discoloration.

The molten flux retards oxidation and

dissolves excess aluminum oxide to

produce high quality deposits.

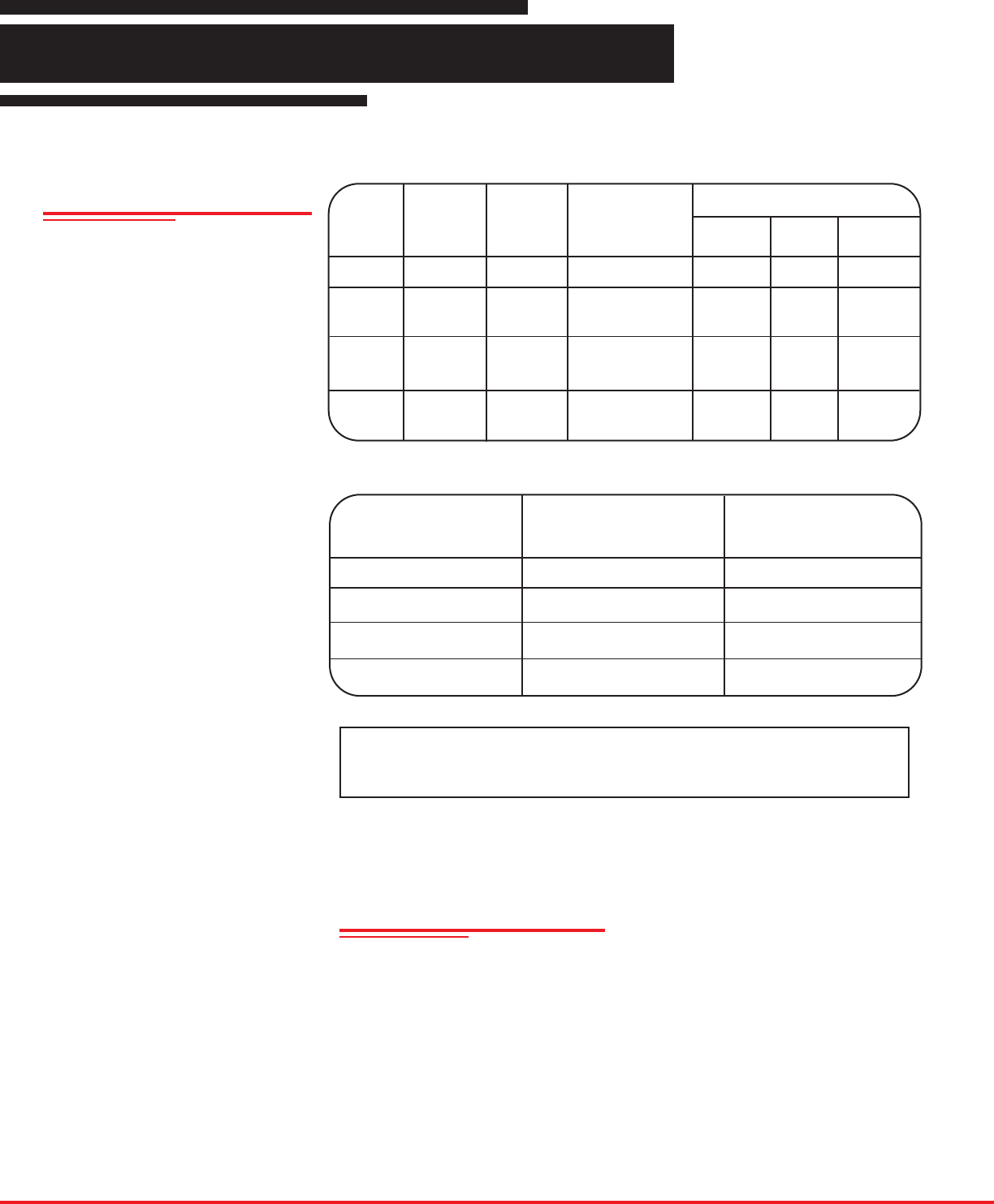

Electrode

Coating

Color

Marking

Printed on

Coating

Electrode Polar-

ity

Sizes and Current Ranges

(Amps)

3/32” Size

(2.5mm)

1/8” Size

(3.2mm)

5/32” Size

(4.0mm)

Ferroweld

Softweld

55 Ni

Softweld

99 Ni

Aluminweld

43

Black

Black

Black

White

St

NiFe-CI

Ni-CI

None

--

40-65

50-65

50-80

50-80

---

80-120

70-95

80-95

80-110

85-120

85-135

---

100-135

110-135

100-140

110-150

110-165

DC(+); AC

DC(+)

AC

DC(+)

AC

DC(+)

ELECTRODE IDENTIFICATION AND OPERATING DATA

ELECTRODE CONFORMANCES, APPROVALS & TYPICAL PROPERTIES

Electrode

Conforms to Test Re-

quirements of AWS

Specifications

Class

Ferroweld

Softweld 55 Ni

Softweld 99 Ni

Aluminweld 43

A5.15

A5.15

A5.15

A5.3

ESt

ENiFe-CI

ENi-CI

E4043

The serviceability of a product or structure utilizing this type of information is and must be the sole respon-

sibility of the builder/user. Many variables beyond the control of The Lincoln Electric Company affect the

results obtained in applying this type of information. These variables include, but are not limited to, weld-

ing procedure, plate chemistry and temperature, weldment design, fabrication methods and service re-

quirements.

The majority of cast iron parts are

gray cast iron. These guidelines

are limited to welding this material.

Because of its hard and brittle

structure, welding white cast iron is

generally impractical. Malleable,

nodular, and other heat treated types

of cast iron usually require heat treat-

ing after welding to restore the

strength and ductility requirements to

the part. Although they can be

welded, the special procedures and

heat treating required makes repair

welding these materials expensive.

How to Locate Cracks - A simple

but effective way of locating surface

cracks is to use commercial dye

penetrant methods. As an alternate,

you can swab the damaged area with

a kerosene soaked rag to remove

grease and dust. Immediately chalk

over the area with common