B-4

OPERATION

B-4

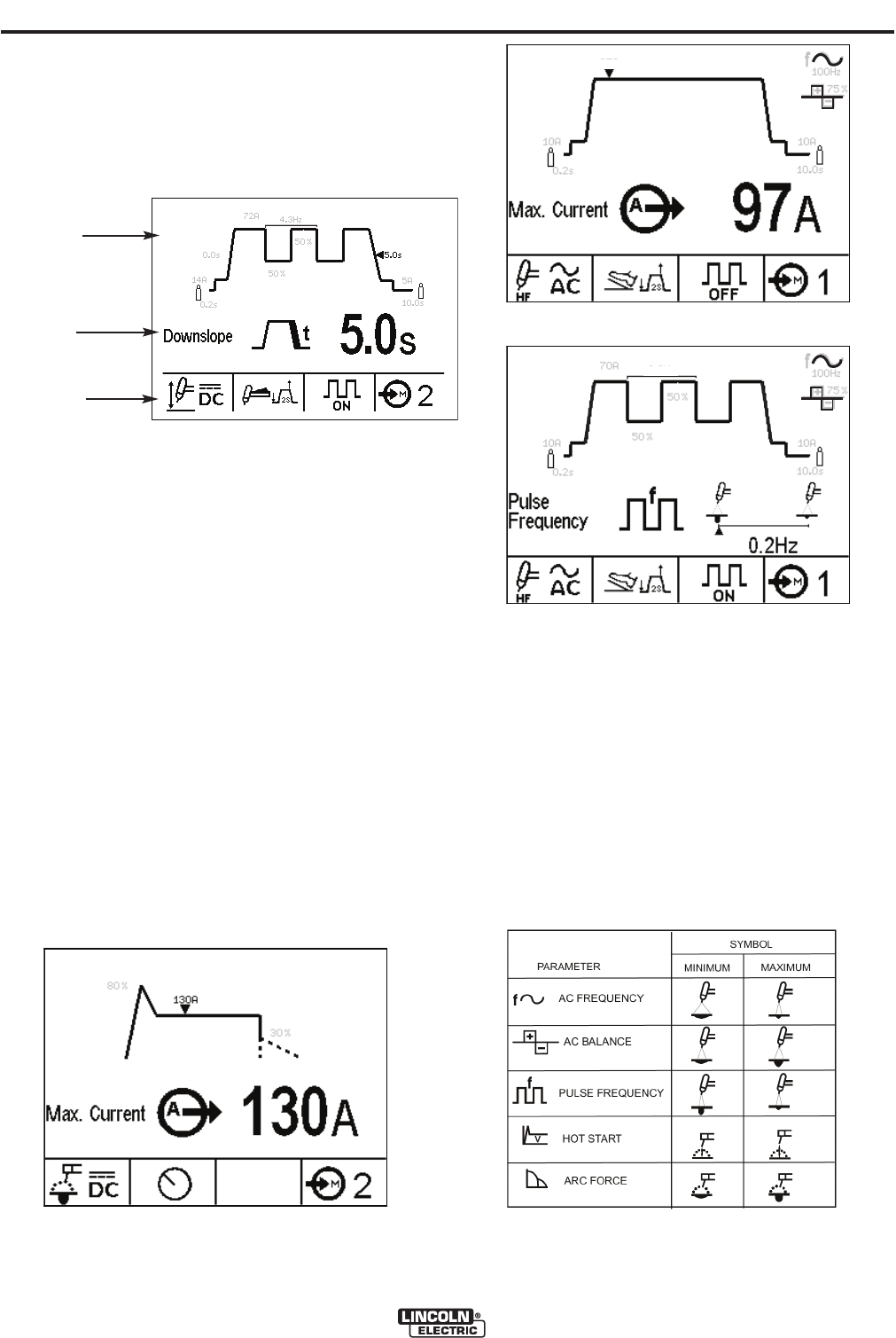

DYNAMIC LCD DISPLAY

The Dynamic display is divided into several sections

(Refer to Figure B.4):

Figure B.4

1. The Weld Sequence Diagram shows the various

parameters that can be selected and adjusted and

their preset values. As the push button/rotary

encoder is pressed a triangular shaped flashing

indicator will highlight the adjustable parameter on

the sequence diagram in bold. Each press of the

encoder will scroll to the next selected parameter

sequentially. Rotating the push button encoder will

change the selected parameter value. The display

is dynamic in that adjusting the selected parameter

dynamically changes the shape of the sequence

diagram. After 5 seconds of inactivity the selected

parameter will default back to the weld output amps

parameter. Depressing the button again will

remember the last selected parameter and begin

the sequential scroll from that parameter.

Three Sequence Diagram types exist:

• STICK (See Figure B.4a)

• TIG (See Figure B.4b)

• Pulse TIG (See Figure B.4c)

2. The Parameter Display Section shows the select-

ed parameter its display icon and preset value. To

change the value, rotate the push button/rotary

encoder. Some parameters like AC Frequency have

an Enhanced Icon Display that shows the effect of the

varying parameter on the arc and/or weld bead profile.

As these parameters are adjusted an indicator will

move between the minimum and maximum icon to

show the relative effect of that parameter. Pulse

Frequency shown in Figure B.4c is an example of the

enhanced icon display. Refer to Table B.1 for a list of

Enhanced Icons.

INVERTEC® V311-T AC/DC TIG

0

.0s

0.2s

1

4A

7

2A

4

.3Hz

5

0%

5

0%

5

.0s

5A

1

0.0s

1. Weld Sequence

Diagram

2. Parameter

Display

3. Mode Push Button

Indicators

80%

30%

1

0A

10A

100Hz

10.0s

0.2s

f

+

-

75%

97A

10A

100Hz

10.0s

0.2s

f

+

-

75%

70A

50%

50%

10A

0.2Hz

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

Figure B.4a

Figure B.4b

Figure B.4c

Table B.1