B-2

OPERATION

B-2

DESIGN FEATURES AND ADVANTAGES

FOR STICK WELDING

• Excellent DC constant current output for stick weld-

ing applications.

• Continuous adjustment of both voltage and current

for unsurpassed welds on demanding jobs.

• Remote control capability standard.

FOR AUXILIARY POWER

• 3,000 watts of 115/230 VAC, 60 Hz auxiliary power.

• One 20 amp 115 VAC duplex receptacle for up to 26

amps of 115 VAC power.

• One 15 amp, 230 VAC duplex receptacle for up to 13

amps of 230 VAC power.

• Weld and AC auxiliary power at the same time (with-

in the limits shown on the chart below).

OTHER FEATURES

• Perkins 4-cylinder, water cooled diesel engine.

Designed for long life, easy maintenance and excel-

lent fuel economy.

• Engine protection system shuts the engine down for

low engine oil pressure or high coolant temperature.

• Electronic Engine Idler. Engine automatically goes to

low idle in 10 to 14 seconds after welding or use of

auxiliary power stops. Includes high idle switch.

• Gauges for engine oil pressure, coolant temperature

and battery charging ammeter.

• Engine hour meter standard.

• Extended range 22.5 gallon (85.1 L) fuel tank.

DUTY CYCLE

Duty cycle is based on a ten minute period and opera-

tion in an ambient temperature of 104°F(40°C).

The SAE-400 SEVERE DUTY IS NEMA rated at 60%

duty cycle. Duty cycle is based on a ten minute period.

Therefore, a 60% duty cycle welder can be operated at

nameplate rated output for 6 minutes out of every 10

minute period without overheating.

The auxiliary power can be used continuously (100%

duty cycle) within its rated current capacities.

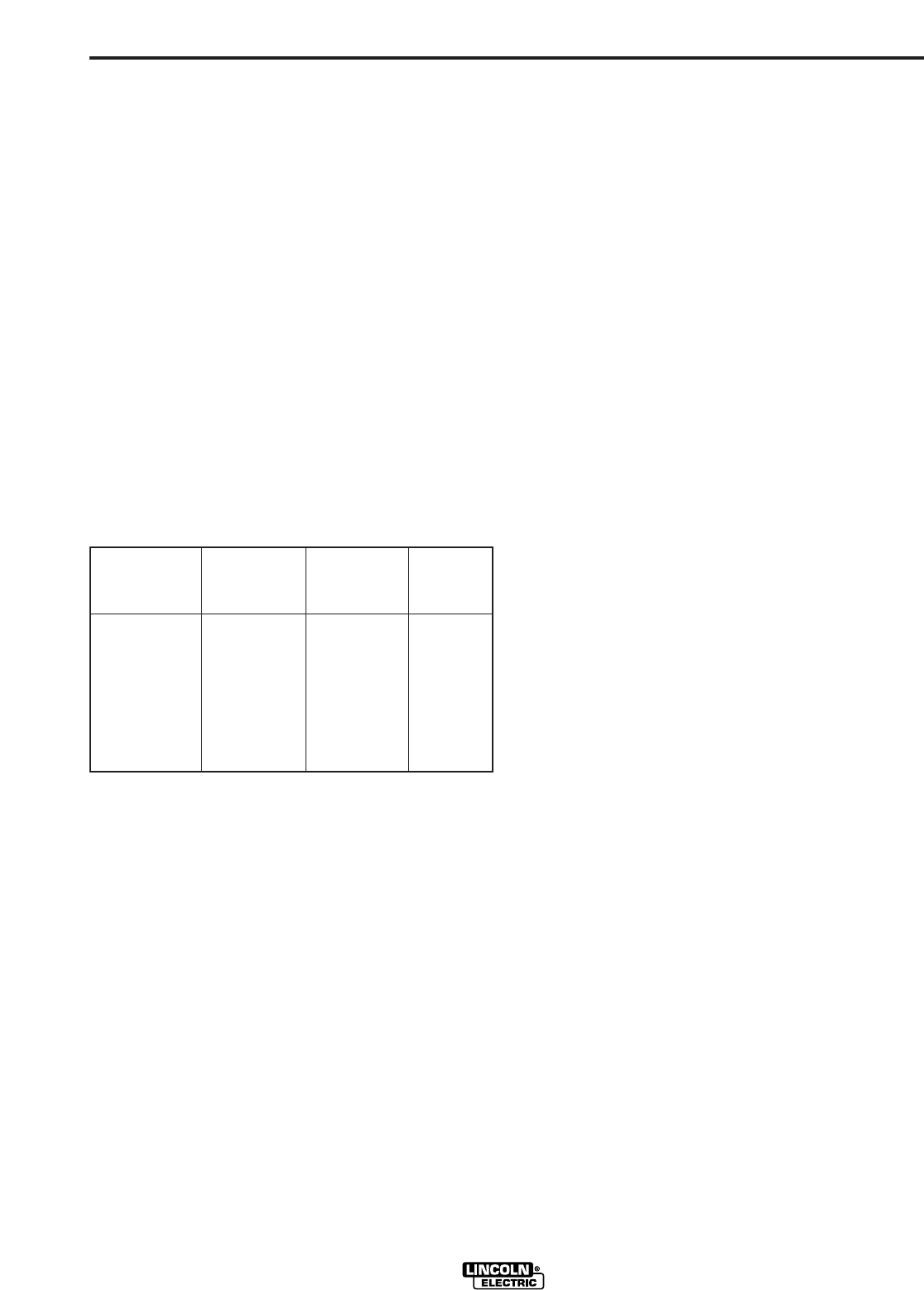

SAE-400 SEVERE DUTY

Welding Using Only Using Only Total

Current, Amps 115V Circuit, 230V Circuit, Aux.

@ NEMA Arc Amps Amps kVA

Volts

0 26 13 3.0

100 19.5 9.75 2.25

200 13 6.5 1.5

300 6.5 3.25 0.75

400 0 0 0