Be sure to read and understand the warnings on this welding machine and the section on ARC WELDING SAFETY PRECAUTIONS in

the Operating Manual. Because design, fabrication, assembly and welding variables affect the results obtained in applying this type

of information, the serviceability of a product or assembly is the responsibility of the builder/user.

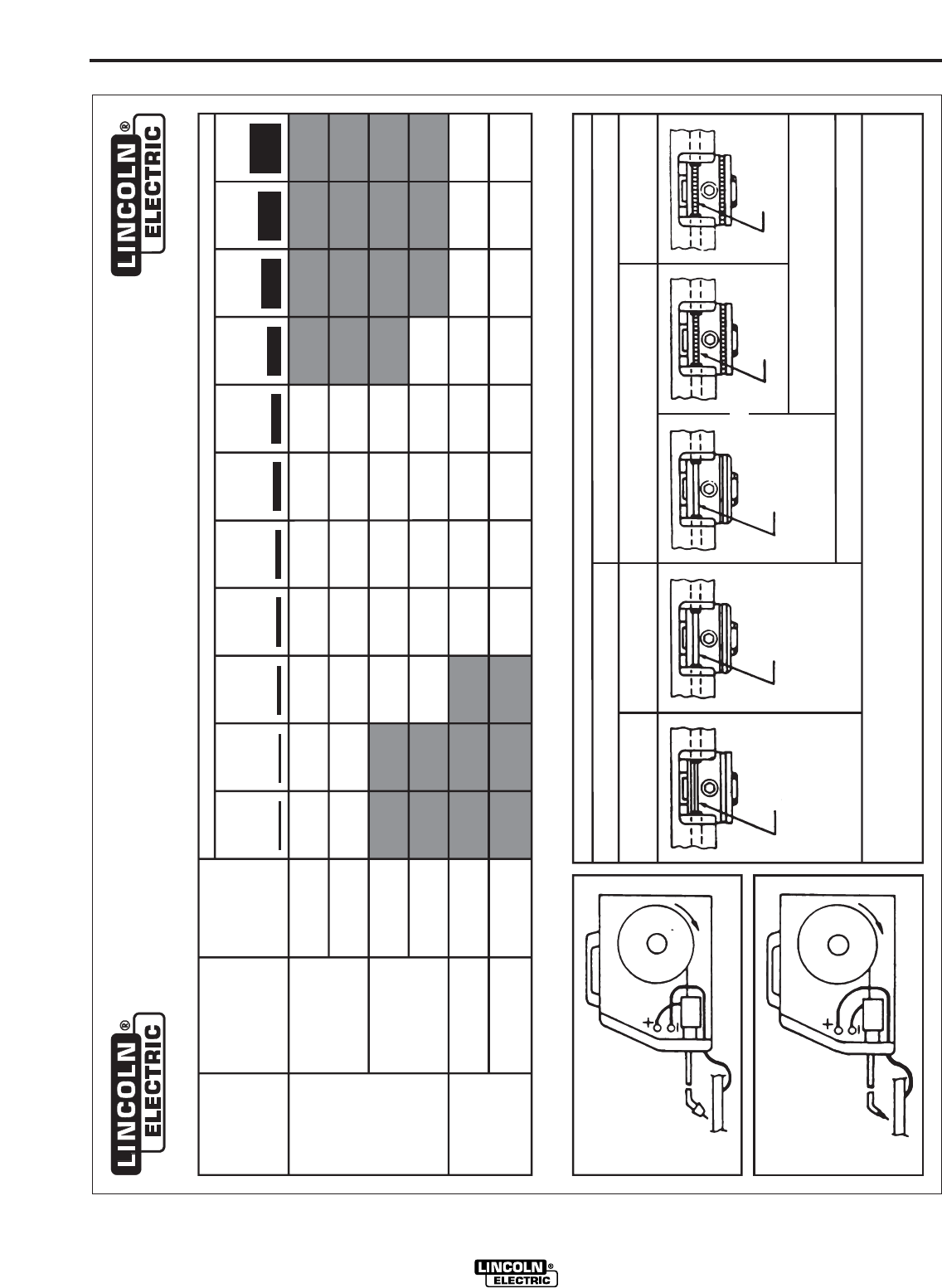

SUGGESTED SETTINGS FOR WELDING

ADJUST FOR OPTIMUM WELDING

FOR STAINLESS STEEL AND ALUMINUM SETTINGS - SEE MANUAL

STEEL THICKNESS

PROCESS

WELDING WIRE

SHIELDING

GAS

MIG

DC(+)

.025 in. (0.6 mm) DIA.

SOLID STEEL WIRE

.030 in. (0.8 mm) DIA.

SOLID STEEL WIRE

GASLESS

FLUX-CORED

DC(-)

.035 in. (0.9 mm) DIA.

INNERSHIELD

NR

®

-211-MP

CO2

C20 or C25

(

75-80% Argon,

25-20% CO

)

2

CO2

NONE

.024 in.

0.60 mm

.135 in.

3.5 mm

.030 in.

0.80 mm

.036 in.

1.0 mm

.048 in.

1.2 mm

.060 in.

1.6 mm

.075 in.

2.0 mm

.105 in.

2.5 mm

3/16 in.

5.0 mm

1/4 in.

6.0 mm

B-2B-2B-2C-3C-3D-5

A-2 A-2 B-3

B-4 C-5

B-2C-3C-3D-4

B-3B-3C-3D-5

A-1 A-1 B-2 B-2 C-2.5

D-2

E-2*

* Multiple passes required

OUTPUT POLARITY DRIVE ROLL ORIENTATION

MIG

DC(+)

ALIGN GROOVE WITH CENTER OF GUIDE TUBES, SECURE DRIVE ROLL WITH SET SCREW CENTERED ON FLAT

MIG DC(+)

.025 (0.6 mm) DIA.

SOLID STEEL WIRE

.030 (0.8 mm) DIA.

SOLID STEEL WIRE

.035 (0.9 mm) DIA.

INNERSHIELD NR

®

-211-MP

.035/.045 liner and appropriate tip must be installed in gun - see manual.

L10732 SP170-I

GASLESS FLUX-CORED DC(-)

.045 in. (1.2 mm) DIA.

INNERSHIELD

NR

®

-211-MP

NONE

E-7.5

D-6

E-6.5

E-8 E-8

E-2.5*

A-1 B-1

B-1

C-1.5

C-1.5

5/16

8.0 mm

.045 (1.2 mm) DIA.

INNERSHIELD NR -211-MP

®

-- OR --

Optional knurled drive roll for .035 and .045 wire

included in the .045 (1.2 mm) Innershield Kit.

SMALL

GROOVE

(BEVEL SIDE)

LARGE

GROOVE

LARGE

GROOVE

EITHER

GROOVE

GASLESS

FLUX-CORED

DC(-)

EITHER

GROOVE

A-2

D-2.5 D-2.5* D-2.5*

C20 or C25

(

75-80% Argon,

25-20% CO

)

2

B-7

SP-170-I

B-7

APPLICATION CHART