B-3

TROUBLESHOOTING

B-3

DEVICENET MODULE

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

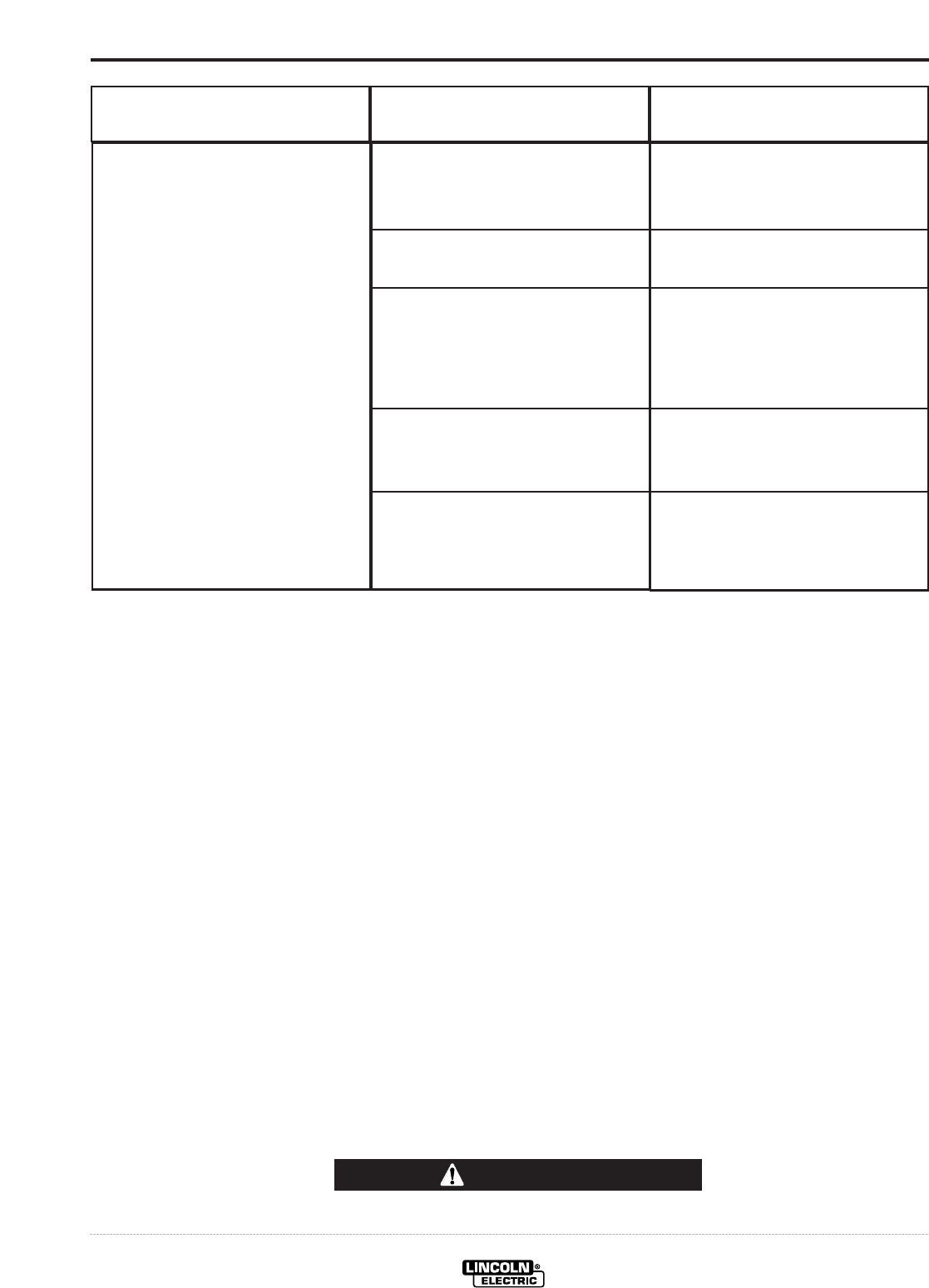

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

Device goes off line during welding

1. Current Interference

2. Termination

3. Shield

4. Power Supply

5. Expected Packet Rate

1. Verify that cables are not run

along current carrying conductors.

This would include the welding

cables.

2. Verify that the DeviceNet bus is

terminated correctly.

3. Verify that the cable shielding is

correctly grounded at the bus

power supply. The shield should

be tied into the bus ground at only

one point.

4. Verify that the power supply can

supply more than enough current

for the devices in the network.

5. Verify that 1000/(Expected Packet

Rate) ≤ (scans per seconds). The

Monitor section of the Observer

application displays these values.

For more trouble shooting of a DeviceNet network the following references should be used.

Allen-Bradley Cat. Num. DN-6.7.2

Rockwell Automation Document 8842

ODVA web site (www.odva.org)