Cobramatic

®

Owner’s Manual - page 4

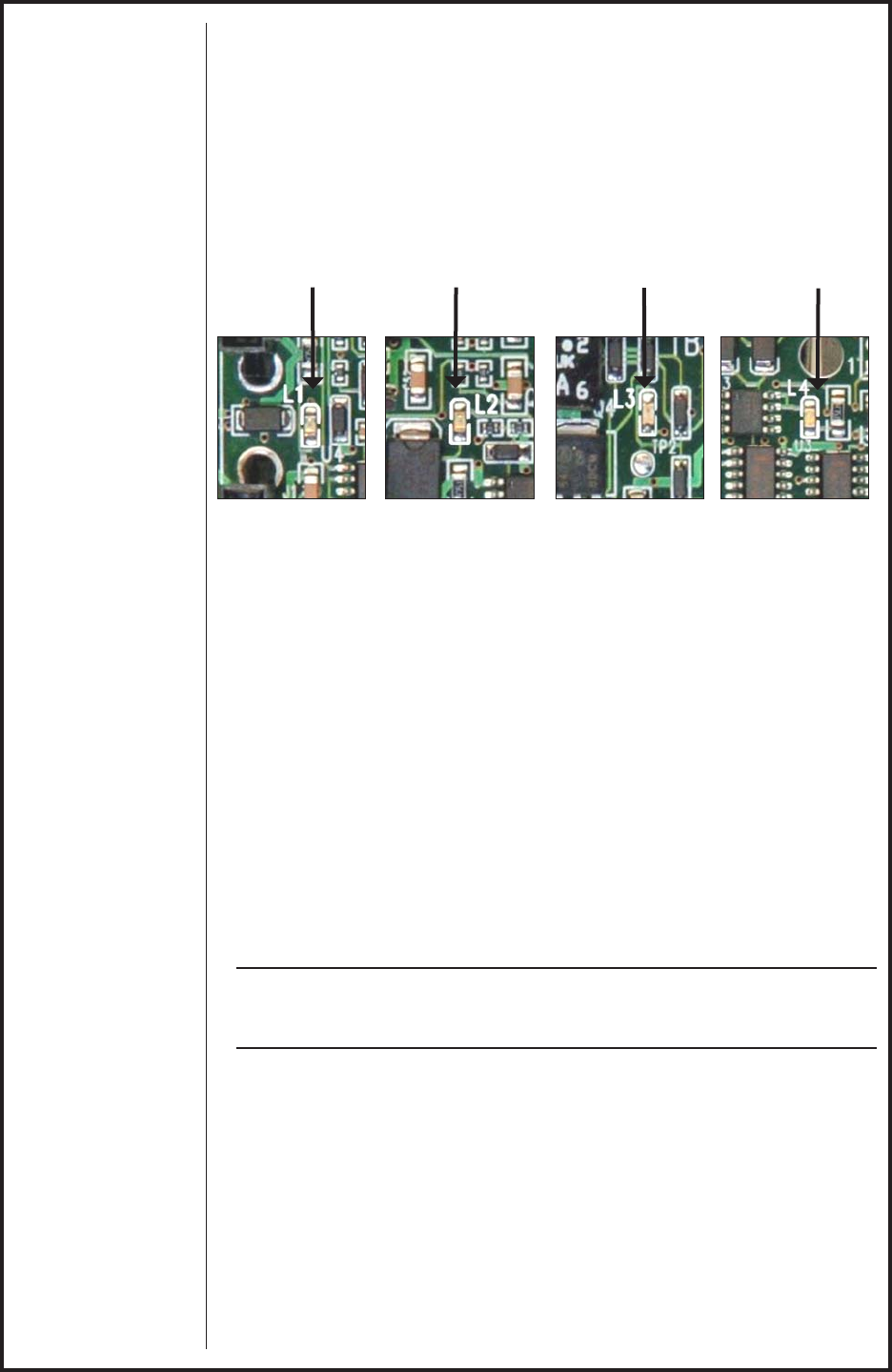

The normal operating sequence of the wire feeder can be viewed on the

board itself via sequence LED’s. When the system is triggered, the green

Trigger LED (L3) and the yellow Gas Solenoid LED (L1) illuminate simultane-

ously. The red Contactor/Wire Feed LED (L2) illuminates after the prepurge

time. The blue Arc On LED (LED) illuminates as the arc is established. When

the trigger is released the normal LED operating sequence is blue, green and

red (L4, L3, & L2) turn off simultaneously followed by the yellow (L1) after the

postpurge time has elasped (Figure 4).

Recommended Processes and Equipment

The Cobramatic

®

is recommended for use in the GMAW and FCAW weld-

ing applications. It is recommended for use with constant voltage power

sources. The Cobramatic

®

is capable of feeding wires (diameter capacity)

ranging from .030” through .045” solid/cored and .030” through 1/16” alumi-

num.

Controls and Settings

On/Off Switch

Placing the switch in the “ON” position energizes the feeder circuitry and the

power indicator light.

Wire Size Selector Switch

The wire size selector switch changes the torque of the slave motor for the

wire you are using. When in the .030” - .035” aluminum only position, the

slave motor produces approximately 1 1/2 lbs inches and approximately

4 1/2 lbs inches when in the all other wires position.

NOTE:

Operating the cabinet with the switch in the wrong

position will cause wire feed difficulties.

PosaStart Switch & Run Speed Setting

The Posa Start Run-in Speed Control, located on the front panel, provides

wire speed adjustment for slow wire run-in. This setting tracks as a percent-

age of the welding wire speed setting. Once the arc has been established,

the wire feed speed automatically changes from the slow run-in speed to the

welding wire speed set on the gun potentiometer.

PosaStart operation and configuration is explained later in this section.

Trigger Normal/Trigger Latched

This switch configures the electronic Trigger Latching mechanism. In the

Trigger Normal mode, pull and hold the trigger to start welding functions

- release to stop welding functions. In the Trigger Latched mode, pull and

Figure 4 - L1, L2, L3 & L4

Blue LED

when arc established

L4

Yellow LED

when solenoid

opens.

L1

Red LED when

wire feeds/con-

tactor closes.

L2

Green LED

when triggered.

L3

FOR REFERENCE, SEE MAIN P.C. BOARD CONNECTIONS PICTURE IN SECTION F