Adjusting blade gauge

itself

t

,

Constant use of

a

blade gauge leads to wear

on the inside flank, resulting in improper

settings.

To

compensate for this, the blade

gauge itself must be adjusted. If, for ex-

ample, you notice

that

the

blade

is

below

the

level

of

the rear shoe, you probably are

not able to actually plane

-

so

the blade

must protrude more. But, if turning the

depth knob

all

the way fails to make the

blade protrude sufficinetly for planing,

n

/

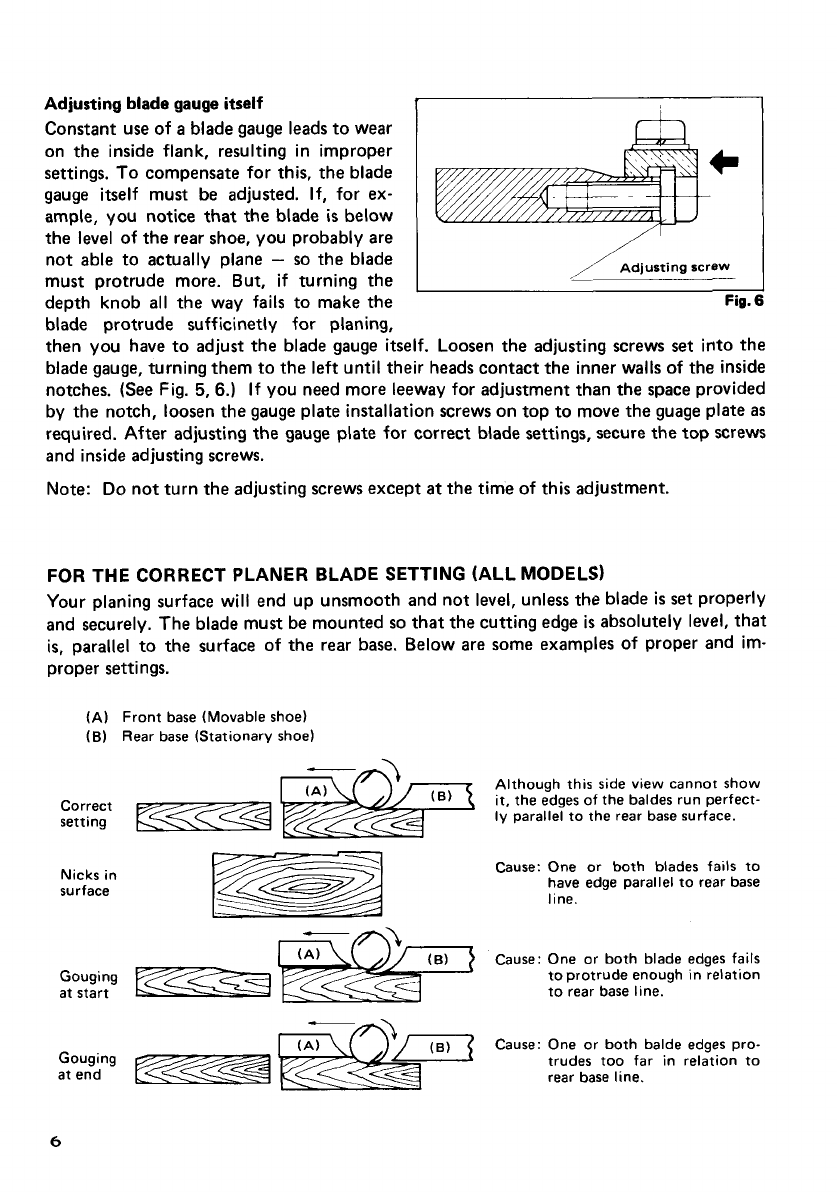

Adjusting screw

Fig.

then you have to adjust the blade gauge itself. Loosen the adjusting screws

set

into the

blade gauge, turning them to the left until their heads contact the inner walls of the inside

notches.

(See

Fig.

5,6.)

If

you need more leeway for adjustment than the space provided

by the notch, loosen the gauge plate installation screws on top to move the guage plate

as

required. After adjusting the gauge

plate

for correct blade settings, secure the

top

screws

and inside adjusting screws.

Note:

Do

not turn the adjusting screws except

at

the time of this adjustment.

FOR

THE CORRECT PLANER BLADE SETTING (ALL MODELS)

Your planing surface will end up unsmooth and not

level,

unless the blade

is

set

properly

and securely. The blade must be mounted

so

that the cutting edge

is

absolutely

level,

that

is,

parallel to the surface

of

the rear base. Below are some examples of proper and im-

proper settings.

(A) Front base (Movable shoe)

(B)

Rear base (Stationary shoe)

setting

Correct

=

m

Although

this

side view cannot show

it,

the edges of the baldes run perfect-

ly

parallel to the rear base surface.

Cause: One or both blades fails to

have edge parallel to rear base

line.

m?)

Cause: One or both blade edges fails

to protrude enough

in

relation

to rear base line.

at start

-

Gouging

~~

E2aT(

Cause: One or both balde edges pro-

trudes too far

in

relation to

at end rear base line.

6