5

ENGLISH

Explanation of general view

1 Hex wrench

2 Shaft lock

3Tighten

4Loosen

5 Saw blade

6 Outer flange

7 Inner flange

8 Outer flange

9 Hex socket head bolt

10 Saw blade

11 Setting protuberances

12 Hex socket head bolt

(For adjusting riving knife)

13 Cutting depth

14 Loosen

15 Lever

16 Thumb nut

17 For 45° bevel cuts

18 For straight cuts

19 Base plate

20 45° angle cuts

21 Straight cuts

22 Top guide

23 Base

24 60° angle cuts

25 45° angle cuts

26 30° angle cuts

27 Straight cuts

28 Blade

29 Base

30 Top guide

31 Lock-off button

32 Switch trigger

33 Vacuum cleaner

34 Limit mark

35 Brush holder cap

36 Screwdriver

SPECIFICATIONS

Model 5603R 5703R 5903R 5103R 5143R

Blade diameter ............................................... 165 mm 190 mm 235 mm 270 mm 355 mm

Max. cutting depth

At 90° .......................................................... 54 mm 66 mm 85 mm 100 mm 130 mm

At 45° .......................................................... 38 mm 46 mm 64 mm 73 mm 90 mm

No load speed (min

–1

) ................................... 5,000 4,800 4,500 3,800 2,700

Overall length ................................................ 330 mm 356 mm 400 mm 442 mm 607 mm

Net weight ...................................................... 4.2 kg 5.2 kg 7.6 kg 9.4 kg 14.5 kg

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed Safety

instructions.

SPECIFIC SAFETY RULES

GEB029-1

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to circular saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious per-

sonal injury.

Danger:

1. Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary han-

dle, or motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below the

workpiece. Do not attempt to remove cut material

when blade is moving.

CAUTION: Blades coast after turn off. Wait until

blade stops before grasping cut material.

3. Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade teeth

should be visible below the workpiece.

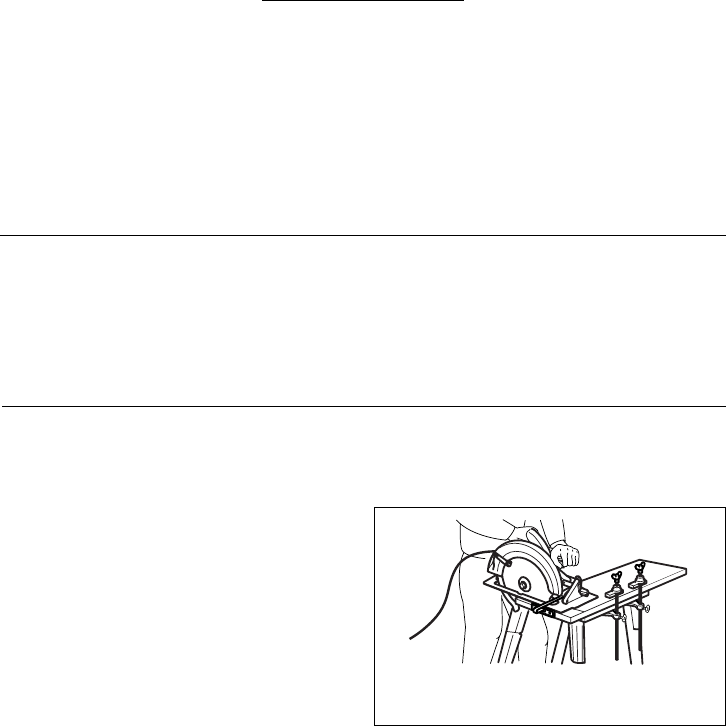

4. Never hold piece being cut in your hands or

across your leg. Secure the workpiece to stable

platform. It is important to support the work properly

to minimize body exposure, blade binding, or loss of

control. (Fig. A)

Fig. A

5. Hold power tool by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the

operator.

6. When ripping always use a rip fence or straight

edge guide. This improves the accuracy cut and

reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes. Blades

that do not match the mounting hardware of the saw

will run eccentrically, causing loss of control.

8. Never use damaged or incorrect blade washers

or bolt. The blade washers and bolt were specially

designed for your saw, for optimum performance and

safety of operation.

A typical illustration of proper hand support, work-

piece support, and supply cord routing (if applicable).