8

26. Wear a dust mask and hearing protection when

use the tool.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

Removing or installing saw blade

The following blade can be used with this tool.

The thickness of the riving knife is 1.8 mm for Models

5603R and 5703R or 2.0 mm for Model 5903R and

5103R or 2.5 mm for Model 5143R.

CAUTION:

• Do not use saw blades which do not comply with the

characteristics specified in these instructions.

• Do not use saw blades the disc of which is thicker or

the set of which is smaller than the thickness of the riv-

ing knife.

To remove the saw blade, depress the shaft lock fully to

prevent shaft rotation, then use the hex wrench to loosen

the hex socket head bolt. (Fig. 1)

Now remove the outer flange, raise the safety cover as

much as possible, and remove the saw blade. (Fig. 2)

Install the saw blade using the reverse of the removal

procedure. Install the inner flange, saw blade, outer

flange and hex socket head bolt, in that order. Be sure to

secure the hex socket head bolt tightly with the shaft lock

fully depressed. (Fig. 1 & 3)

CAUTION:

• Make sure that the blade teeth point forward in the

same direction as the tool rotation (the arrow on the

blade should point in the same direction as the arrow

on the tool).

• Never depress the shaft lock while the saw is running.

• Use only the Makita socket wrench to remove or install

the blade.

Riving knife adjustment (Fig. 4)

Use the socket wrench to loosen the hex head socket

bolt for the riving knife adjustment, then raise the safety

cover. Move the riving knife up or down over the two pro-

tuberances for settings indicated in the illustration, so as

to obtain the proper clearance between the riving knife

and saw blade.

CAUTION:

Ensure that the riving knife is adjusted such that: The dis-

tance between the riving knife and the toothed rim of the

saw blade is not more than 5 mm. The toothed rim does

not extend more than 5 mm beyond the lower edge of the

riving knife.

Adjusting depth of cut (Fig. 5)

Loosen the lever on the depth guide and move the base

up or down. At a desired depth of cut, secure the base by

tightening the lever.

CAUTION:

• Use a shallow depth of cut when cutting thin workpiece

for cleaner, safer cuts.

• After adjusting the depth of cut, always tighten the lever

securely.

Adjusting for bevel cuts (Fig. 6)

Loosen the thumb nuts in front and back, and tilt the tool

to the desired angle for bevel cuts (0–45°). Secure the

thumb nuts tightly in front and back after making the

adjustment.

Sighting (5603R, 5703R) (Fig. 7)

For straight cuts, align the right notch on the front of the

base with your cutting line on the workpiece. For 45°

bevel cuts, align the left notch with it.

Top guide (5903R, 5103R) (Fig. 8)

Align your sight line with either the 0° notch for straight

cutting or the 45° notch for 45° angle cuts.

Top guide (5143R) (Fig. 9)

Align your sight line with either the 0° notch for straight

cutting or the 30° notch for 30° angle cuts or the 45°

notch for 45° angle cuts or the 60° notch for 60° angle

cuts.

Switch action (Fig. 10)

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

depress the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

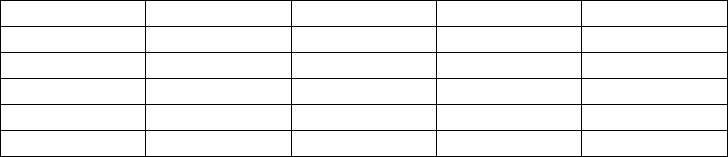

Model Max. dia. Min. dia. Blade thickness Kerf

5603R 165 mm 150 mm Less than 1.7 mm More than 1.9 mm

5703R 190 mm 170 mm Less than 1.7 mm More than 1.9 mm

5903R 235 mm 210 mm Less than 1.9 mm More than 2.1 mm

5103R 270 mm 260 mm Less than 1.8 mm More than 2.2 mm

5143R 355 mm 350 mm Less than 2.3 mm More than 2.7 mm