11

• Hold the tool pointed straight at the screw.

• If you tighten the screw for a time longer than shown in

the figures, the screw or the point of the driver bit may be

overstressed, stripped, damaged, etc. Before starting

your job, always perform a test operation to determine

the proper fastening time for your screw.

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

The fastening torque is affected by a wide variety of factors

including the following. After fastening, always check the

torque with a torque wrench.

1. When the battery cartridge is discharged almost com-

pletely, voltage will drop and the fastening torque will be

reduced.

2. Driver bit or socket bit

Failure to use the correct size driver bit or socket bit will

cause a reduction in the fastening torque.

3. Bolt

• Even though the torque coefficient and the class of

bolt are the same, the proper fastening torque will

differ according to the diameter of bolt.

• Even though the diameters of bolts are the same, the

proper fastening torque will differ according to the

torque coefficient, the class of bolt and the bolt

length.

4. The manner of holding the tool or the material of driving

position to be fastened will affect the torque.

5. Operating the tool at low speed will cause a reduction in

the fastening torque.

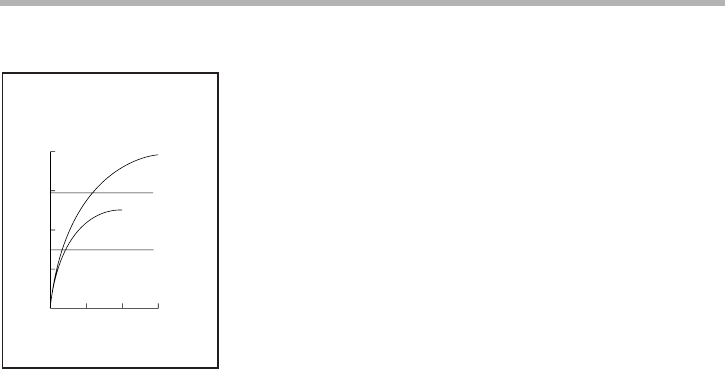

M10(3/8”)

M8(5/16”)

80

60

40

20

0

(14)

(29)

(58)

(43)

1.0 2.0 3.0

N.m

(ft.lbs)

High tensile bolt

(s)

M10(3/8”)

M8(5/16”)

Fatening time

Fastening torque

Proper fastening torque

002796