OM-303 Page 15

SECTION 6 − OPERATION

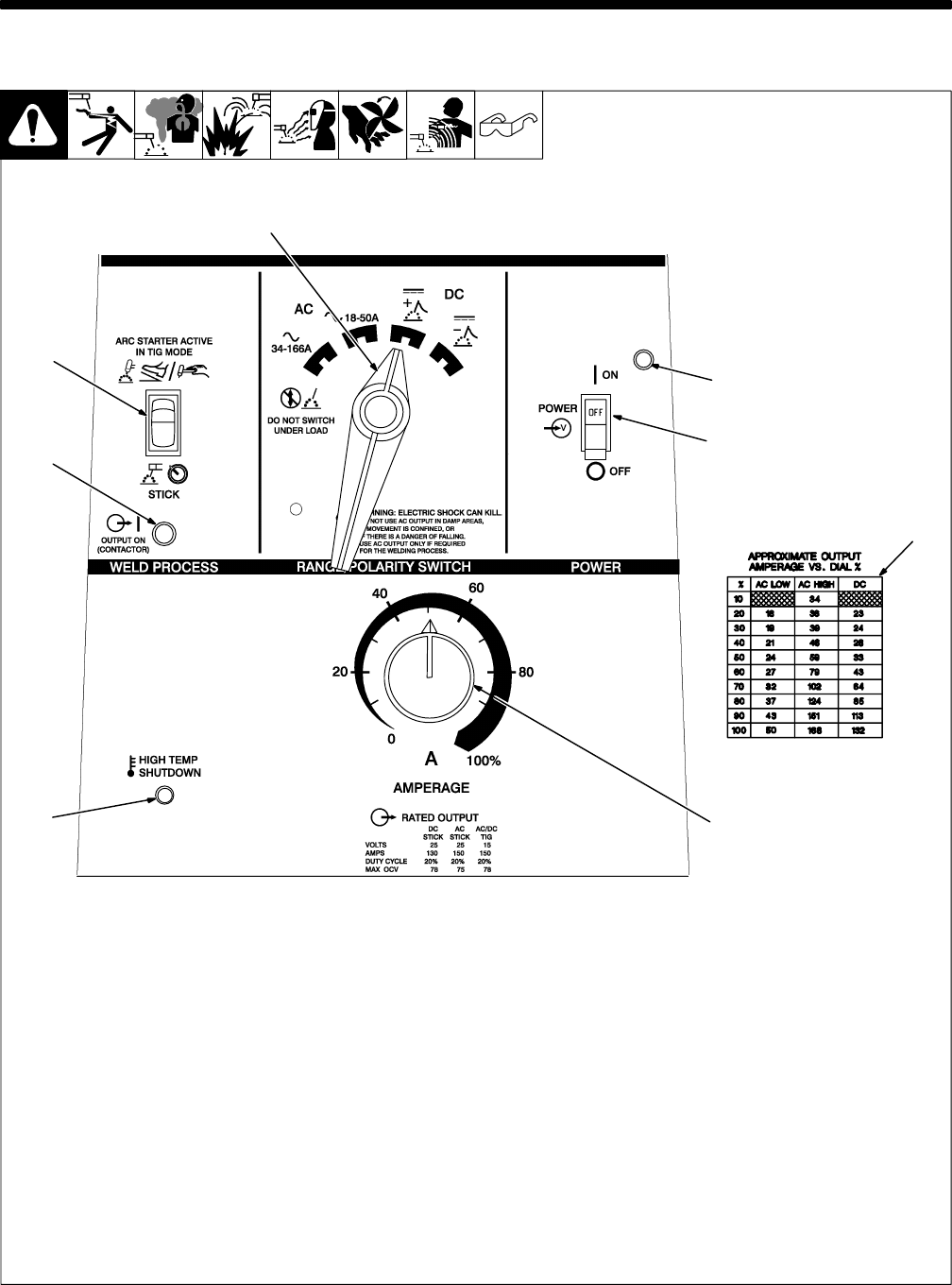

6-1. Controls

Ref. ST-155 790-F

1 Weld Process Switch

Use switch to select weld process.

In Stick position (down), weld output goes On

and Off with Power switch.

In GTAW (TIG) position (up), remote control

device turns on and adjusts weld output of unit

as limited by Amperage control. Built-in arc

starter comes on when needed to start or stabi-

lize welding arc. No adjustments needed for

arc starter.

2 Pilot Light

3 Power Switch

Use switch to turn unit, fan, and pilot light On

and Off.

4 Amperage Control

For Stick (SMAW), use control to adjust amper-

age within range selected by the Range/Polar-

ity Switch.

5 Stick (SMAW) Table

Use table to find approximate Stick amperage

output at Amperage control setting.

See Section 6-2 for example of front panel am-

perage control.

For remote amperage control used when TIG

(GTAW) welding, front panel Amperage control

setting is the maximum amperage percentage

available at the remote control device.

See Section 6-3 for example of remote amper-

age control.

6 Range/Polarity Switch

Use switch to select range and polarity of weld

output.

For Direct Current Electrode Negative

(DCEN), use Electrode Negative position.

For Direct Current Electrode Positive (DCEP),

use Electrode Positive position.

For alternating current (AC), use range needed

for welding application − AC Low or AC High

position − see Warning.

See Section 6-4 to find suggested type of weld

output for application.

7 High Temperature Shutdown Light

Lights when unit overheats and shuts down

(see Section 7-2).

8 Output On (Contactor) Light

Lights when output (contactor) and unit power

are on.

8

5

4

7

2

3

1

6