ENGLISH en

9

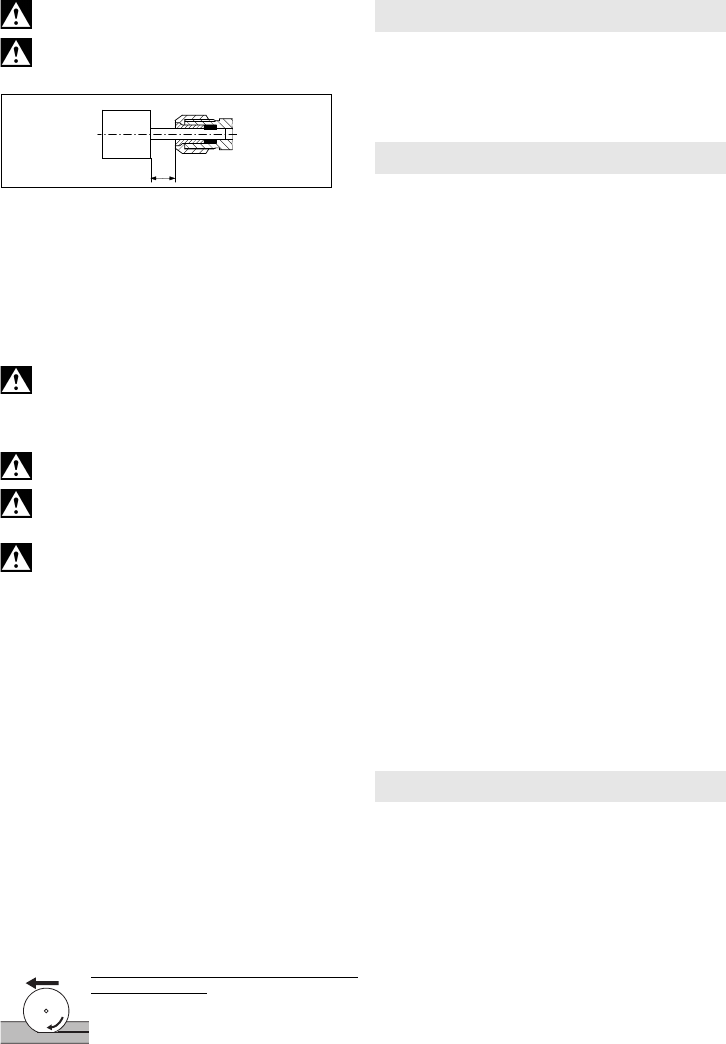

The tool's shank diameter must correspond

exactly to the collet bore of the collet chuck (1)!

For abrasive points, you must never exceed

the maximum open shank length specified by

the manufacturer l

0

.

Insert the tool (with the full length of the shank) in the

collet chuck (1).

Bring the spindle to a standstill. (For the

GE 710 Compact, use the 13-mm spanner provided

for this purpose. For the GA 18 LTX, GE 710 Plus,

GA 18 LTX G and GE 950 G Plus, press the spindle

locking button (4)).

Using the 19-mm spanner, tighten the collet chuck

nut (2).

If there is no tool inserted in the collet chuck,

you can tighten the collet chuck manually

rather than with the spanner.

6.3 Switching On and Off

Switch on first, then guide the

accessory

towards the workpiece.

Avoid inadvertent starts: always switch the

tool off when the plug is removed from the

mains socket or if there has been a power cut.

In continuous operation, the machine

continues running if it is forced out of your

hands. You must therefore always hold the machine

with both hands using the handles provided (3), (5),

(7), stand in a safe position and concentrate while

working.

Switching on: Push the slide switch (6) forward.

For continuous activation, now tilt downwards until

it engages.

Switching off: Press the rear end of the slide

switch (6) and release.

6.4 Adjusting speed (mains powered

machines only)

The speed can be preset using the setting wheel (8)

and is infinitely variable. For a list of speeds, see the

table on page 3.

6.5 Working instructions

Grinding, sanding, polishing or using wire

brushes: Press down the machine evenly and

move it from side to side over the surface.

Routing: Press down the machine evenly.

Separating:

Always work against the run of the disc

(see illustration). Otherwise there is

the danger of the machine kicking

back from the cut out of control. Guide

the machine evenly at a speed suit-

able for the material being processed. Do not tilt,

apply excessive force or sway from side to side.

7.1 Motor cleaning

To clean the motor, apply jets of compressed air

through the rear ventilation slots of the machine

regularly, frequently and thoroughly. Here, the

machine must be held firmly.

8.1 Mains powered machines:

- Overload protection: There is a MAJOR

reduction in load speed. The motor temperature

is too high! Allow the machine to run at idle speed

until it has cooled down.

- Overload protection: There is a SLIGHT

reduction in load speed. The machine is over-

loaded. Reduce the load before continuing to

work.

- Metabo S-automatic safety shutdown: The

machine was SWITCHED OFF automatically. If

the slew rate of the current is too high (for

example, if the machine suddenly seizes or kick-

back occurs), the machine switches off. Switch off

the machine at the slide switch (6). Switch it on

again and continue to work as normal. Try to

prevent the machine from seizing. See section

3.2.

- Restart protection: The machine does not

start. The restart protection is active. If the mains

plug is inserted with the machine switched on, or if

the current supply is restored following an inter-

ruption, the machine does not start up. Switch the

machine off and on again.

8.2 Cordless machines:

- The electronic signal display (10) lights up

and the load speed decreases. The tempera-

ture is too high! Run the machine in idling until the

electronics signal indicator switches off.

- The electronic signal display (10) flashes and

the machine does not start. The restart protec-

tion is active. The machine will not start if the

battery pack is inserted while the machine is on.

Switch the machine off and on again.

Use only genuine Metabo accessories.

Use only accessories which fulfil the requirements

and specifications listed in these operating instruc-

tions.

Fit accessories securely. Secure the machine if it is

operated in a bracket. Loss of control can cause

personal injury.

A Collets (including nut)

dia.

3 mm = 6.31947

dia.

1/8“ = 6.31948

dia.

6 mm = 6.31945

dia.

1/4“ = 6.31949

dia.

8 mm = 6.31946

B Clamping frame 6.27354 for clamping during

work with flexible shafts (tighten clamping

l

o

7. Cleaning

8. Troubleshooting

9. Accessories