5 Operation

The welding machines Invert 130/40 and 130/60 are primary clocked inverters, suitable for manual arc welding with

coated stick electrodes and for direct current TIG welding (optional).

The electrode diameter and the required welding current are selected according to the material to be welded.

3 Commissioning

Caution:

This product is assembled with great care and thoroughly checked. All units undergo a computerised check before

leaving the factory. Please check your machine for transport damage after unpacking. In case such damage is

detected please notify your supplier immediately.

Ensure that mains voltage matches the machine's rated voltage as shown on its name plate. Connect to 230/240 V

AC circuit. The supply circuit need to be protected by a 16 amp time-lag fuse. Operation of other electrical equipment

on the same circuit while welding is limited.

Pure argon (of at least 99.998 % purity) is preferably used for TIG welding. Connection of the TIG torch to the gas

cylinder must be by means of a suitable pressure reducing device (max. 10 bar). The earth cable must have a

minimum lead cross section of 16 mm

2

. After setting the main switch [1] to ON the machine is ready to operate.

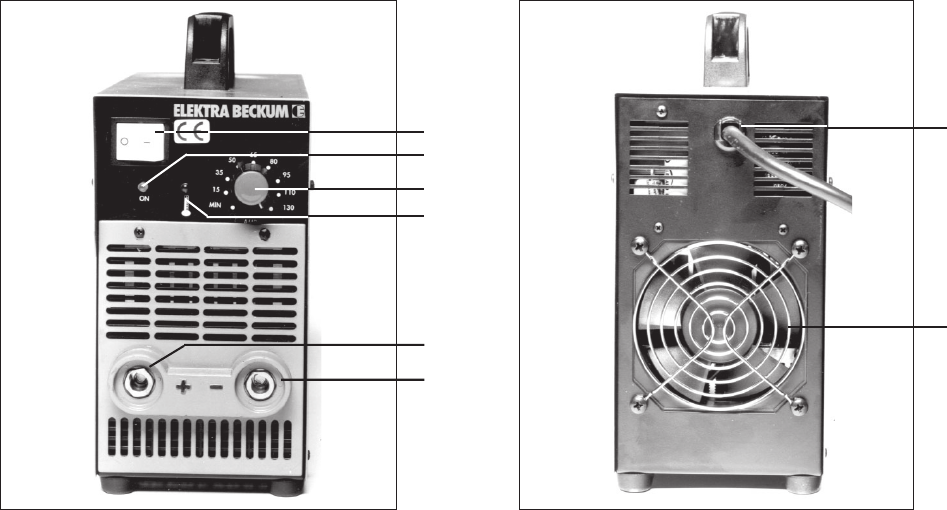

1 Mains ON/OFF switch

2 Welding current setting 5 - 130 A; with integrated automatic hot start

3 Neon control light; indicates thermal overloads or short circuits

4 ON/OFF control light

5 Socket for positive (+) pole; electrode holder, TIG: earth cable

6 Socket for negative (-) pole; earth cable, TIG: torch

7 Power cable

8 Cooling fan

Figure 1: Front panel

4Description

Controls

Figure 2: Rear view

8

7

1

4

2

3

5

6