5

ENGLISH

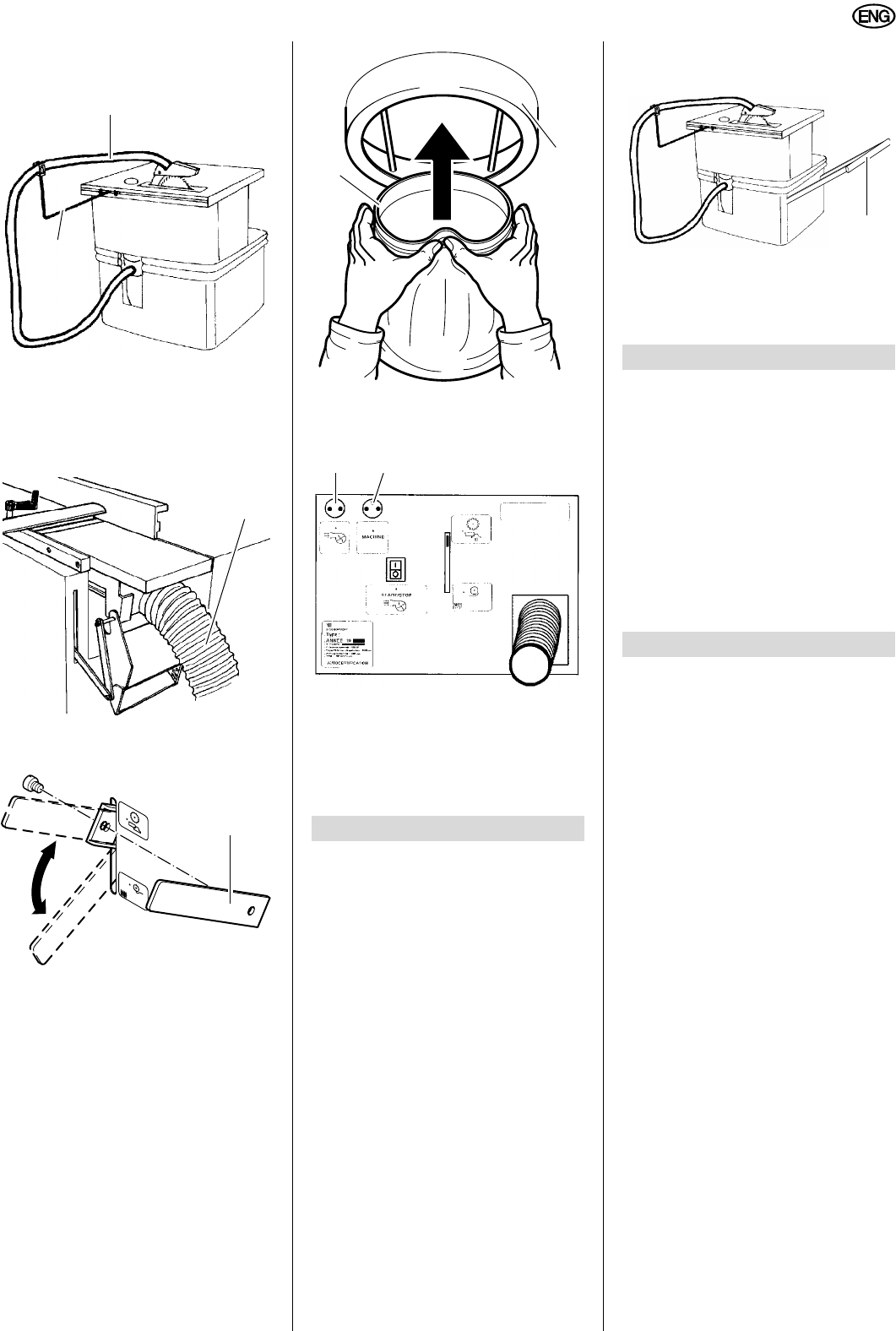

10. Connect the other end of the small

diameter suction hose (43 mm ∅)

(13) to the blade guard.

11. Hang the small diameter suction

hose to the support bracket (14).

12. Connect the long suction hose

(100 mm ∅) (15) to the planer/thick-

nesser’s suction port.

13. Put handle (16) on the selector and

secure with screw.

14. Bend the spring steel ring of the

dust bag (17) inward and fit inside

the receiver (18), up against the

stop.

15. Plug the dust collector’s short cable

into the left outlet (19) of the dust

collector.

16. Connect the combination machine’s

power cable plug to the right outlet

(20) of the dust collector.

17. Connect the long power cable to a

mains outlet.

Commissioning

1. Set the selector:

− Selector in upper position:

collection for circular saw and

spindle moulder.

− Selector in lower position:

collection for planer/thicknesser.

2. Start dust collector.

3. Start woodworking machine.

Stopping

1. Switch woodworking machine OFF.

2. Switch dust collector OFF.

Relocation

1. Pull handle (21) out.

2. With the handle lift the complete

unit, until the wheels touch the floor.

3. Roll unit to the desired location.

Check the dust bag periodically.

If the dust bag is filled:

1. Unplug the dust collector.

2. Open the service door.

3. Push the spring steel ring inward

and remove the dust bag from the

receiver.

4. Dispose of the dust bag’s contents

in an ecologically safe way.

5. Replace the dust bag (see Assem-

bly) and close the service door.

Power supply 230 V / 1 ~ 50 Hz

Power input P

1

: 0.62 kW

Power output P

2

: 0.37 kW

Total power input P

1

(when operated with Combination

machine Multi 180A): 1.72 kW

Mains fuse: 16 A, time-lag

Degree of protection: IP 44

Suction capacity: 600 m

3

/h

Vacuum: 1000 Pa

Dust bag capacity: 68 litres

Suction port Ø: 2 x 100 mm / 1 x 43 mm

Dimensions (L x W x H):

760 x 760 x 500 mm

Weight: 48 kg

Noise emission:

see combination machine

13

14

15

16

4. Operation

18

17

19 20

5. Maintenance

6. Technical Specifications

21