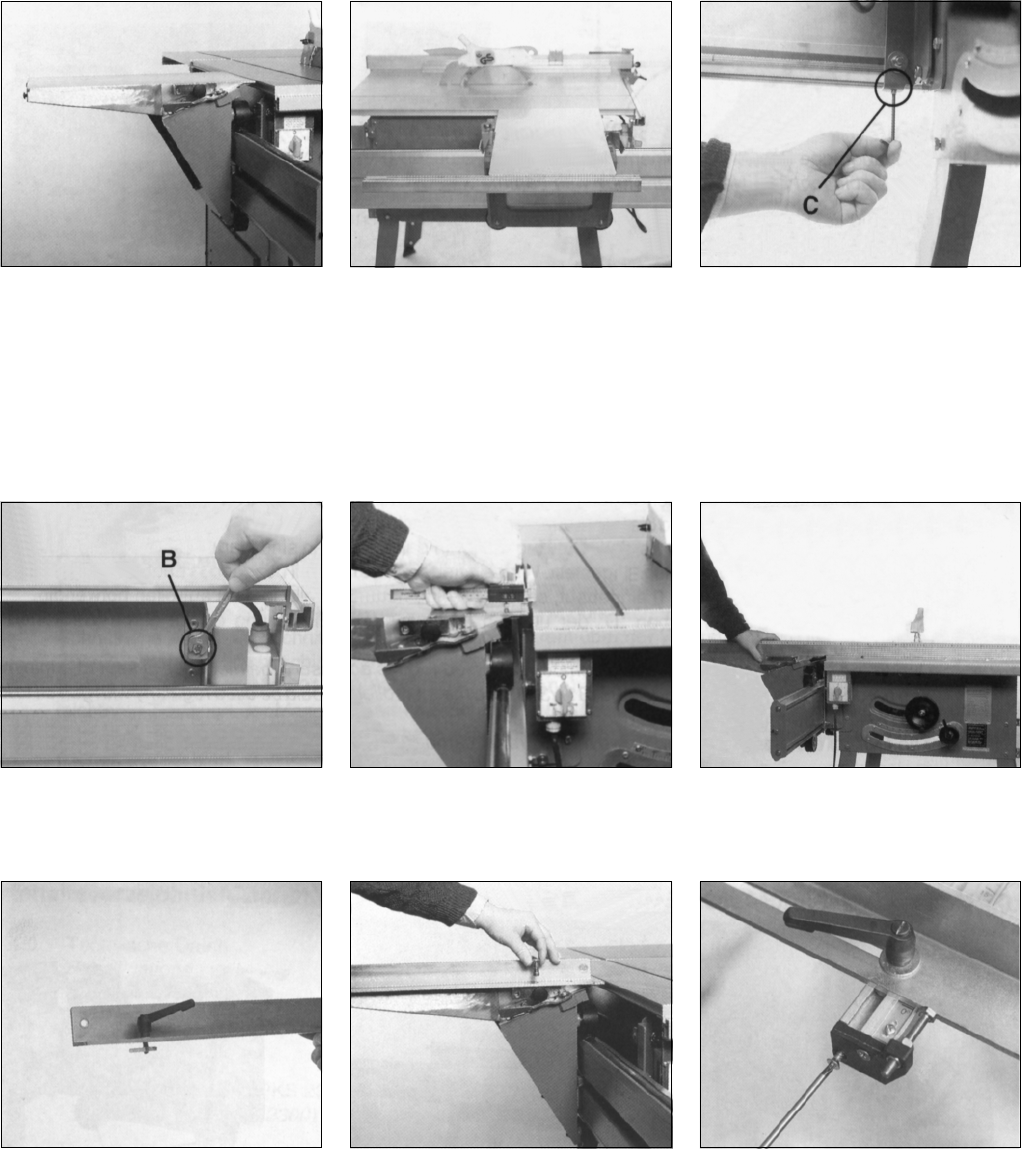

Place table into seats of traversing saddle and

secure with clamp levers (308 & 309). Put a

carriage bolt M6x20 into each of the two holes

and fit with washer B6.4, spring washer B6 and

hex. nut M6. Do not tighten yet.

Slide link bracket extrusion (301) onto heads of

the carriage bolts just installed. Stil bolts need

not to be tightened yet.

The carriage table should be set 0.5 mm (0.020

inch) higher than the saw table. Set by adju-

sting setting screws "C" as required. Make trial

cuts to verify proper operation. Lock counter

nuts of setting screws "C".

4 Support (only for PKS 2300)

- Tap adjustable foot ass'y into square tube with hammer.

- Attach support (347) to roller carrieage extrusion (322) approximately 500 mm/20 in. from the front end.

Use 6 each carriage bolt M8x16, washer A8.4, hex. nut M8. 2 carriage bolt M8x40.

Compensate for uneven floor by turning the adjustable foot ass'y (348) in or out, as required.

The roller carriage extrusion must be set parallel with the machine table by turning setting screw "B", at both front and rear, as required. After setting

lock setting screws in position with counter nuts.

Place ratched lever M8x20 through slot of link

bracket angle bar (307) and attach slide was-

her (329) to threaded pin of ratched lever.

Slide slide washer (329) into recess of link

bracket extrusion (301). Insert mandrel and

lock by lightening starknob screw.

Attach link bracket extrusion end plate (357) to

link bracket extrusion with two countersunk

head tapping screws Ø 4.8x22. Set fence square

to sawblade and slide link bracket extrusion as

required to set to ZERO position. Now fully

tighten the two carriage bolts holding the link

bracket extrusion to the table. Fine tune fence

position with setting screw (414) fitted into link

bracket extrusion end plate (357). Set scale as

required to obtain exact setting.