324 |

ALWAYS THE RIGHT TORCH.

Electrode welding, TIG welding, MIG/MAG welding –

Metabo has the right welding unit for all materials and

for every thickness. However, that is not enough: Our

engineering department is always looking for the latest

technology to enable our customers in craft and industry

to work even more quickly, more rationally and more ef-

WELDING TECHNOLOGY

An overview of welding types.

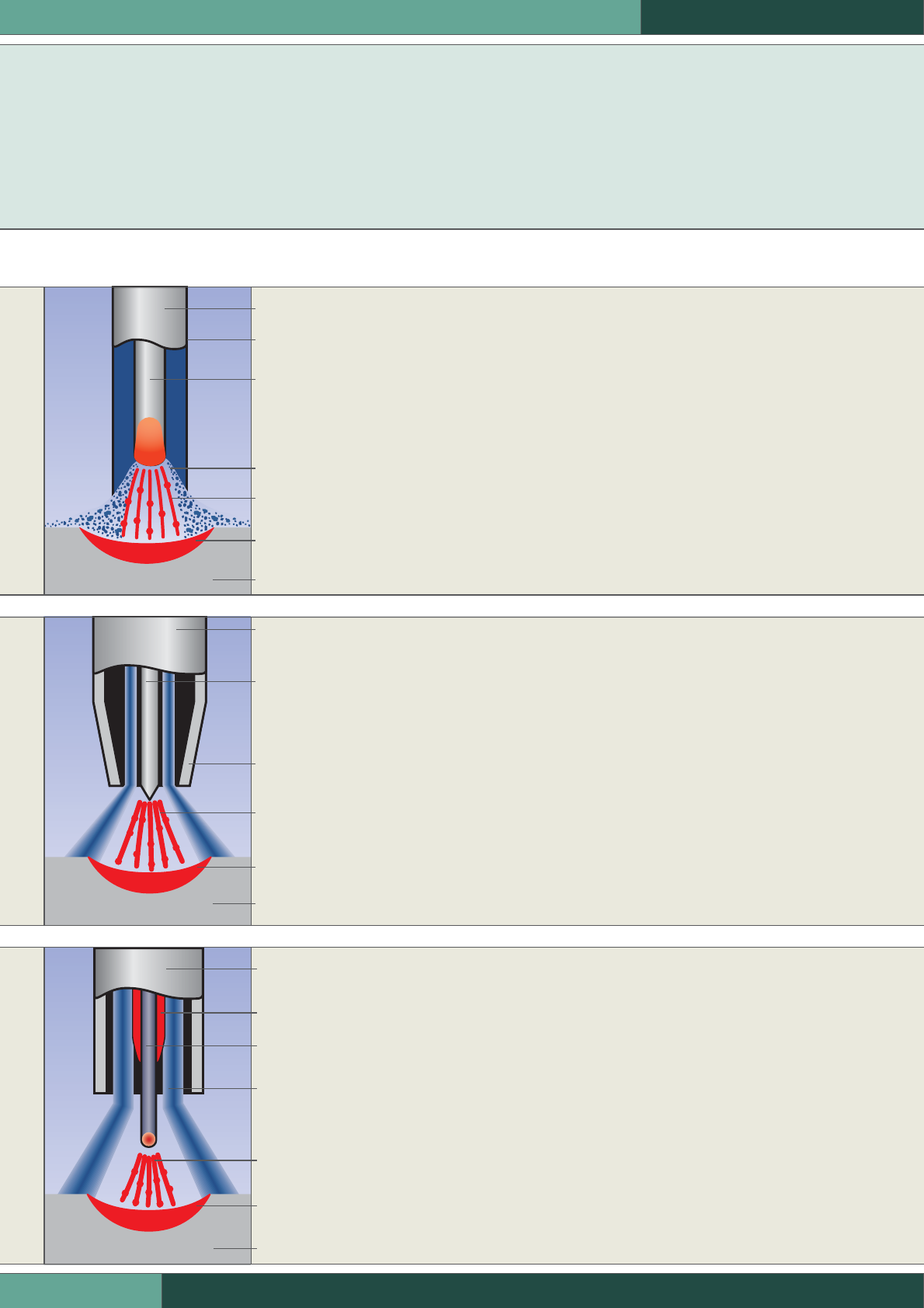

Electrode welding.

TIG welding.

The TIG AC method (alternating

current) must be used for alu-

minium, magnesium and their

alloys (breaking of the oxide layer

on the material).

The advantage of the method is

the good control of the concentra-

ted splatter-free electric arc

(= less delay and rework).

The electric arc burns between

the workpiece and a non-melting

tungsten electrode (TIG = Tungsten

Inert Gas).

A separately fed inert gas (e.g.

Argon (Ar)) protects the welding

zone from negative atmospheric

influences.

Additional material can be fed

manually if required.

The TIG DC (direct current) method

is for welding all metals from

0.3 mm on, except aluminium and

magnesium. (The TIG torch must

always be connected to the nega-

tive pole).

All inverters (electronic devices)

use direct current.

Advantages:

– The electric arc burns more steadily

– Devices can be used with optional

torch for the TIG DC welding

method

The following applies for setting

the welding current in Ampere:

electrode diameter x 40 = welding

current in Ampere.

The electric arc burns between the

workpiece and a melting electrode.

The electrode provides the

additional material.

The melting case forms gases

and slag to protect the electric arc

and melting bath from negative

atmospheric influences.

Can be used for almost all

weldable materials from approx.

1.5 mm on (adapt stick electrodes

to the basic material)

Transformer devices use

alternating current (e.g. SB/SK).

MIG/MAG welding.

pipe steel from approx. 0.5 mm on

in combination with gases mixed

from Argon (Ar) and carbon dio-

xide (CO

2

) or from pure carbon

dioxide (CO

2

).

High alloy steel is processed with

the MAG method using inert Argon

(Ar) gases and a low proportion

(< 5%) of carbon dioxide (CO

2

).

The advantages of the method are

the easy handling and the excellent

thin sheet metal properties.

The electric arc burns between the

workpiece and a mechanically fed

welding wire (electrode).

An automatically fed non-com-

bustible gas protects the electric

arc and the melting bath from

negative atmospheric influences.

The MIG method (MIG = Metal

Inert Gas) is for processing alu-

minium and aluminium alloys.

Argon (Ar), Helium (He) and their

mixtures are used as gases.

The MAG method (MAG = Metal

Active Gas) is used for processing

general construction, tank and

Stick electrode

Casing

Melted zone

Gas/slag

Core rod

Base material

Electric arc

Inert gas nozzle

Flow nozzle

Melted zone

Electrode

Base material

Electric arc

Inert gas

Gas nozzle

Tungsten electrode

Melted zone

Inert gas

Base material

Electric arc