OM-188 304 Page 27

SECTION 6 − PROGRAMS

. Synergic Information: The manufacturer makes no warranties, express or implied, that welds made using the synergic parameters of this equip-

ment will meet the requirements of the application.

The synergic parameters contained in this equipment are intended only to be a general guideline. The choice and use of any synergic setting must

be tested as to its suitability for the application.

6-1. Overview Of Programs

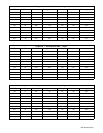

Program # Wire Type Wire Size Shielding Gas IPM: Min IPM: Max

1 Steel .035 in Argon/CO

2

100 780

2 Steel .045 in Argon/CO

2

80 550

3 Stainless .035 in 98% Argon/2% CO

2

100 780

4 Stainless .045 in 98% Argon/2% CO

2

90 620

5 4043AL .035 in Argon 140 870

6 4043AL .047 in Argon 100 730

7 5356AL .035 in Argon 180 880

8 5356AL .047 in Argon 140 730

9 Nickel .035 in 75% Argon/25% Helium 80 780

10 Silicon Bronze .035 in Argon 120 780

11 Metal Core .045 in Argon/CO

2

100 550

12 Metal Core .052 in Argon/CO

2

60 450

6-2. Individual Program Information

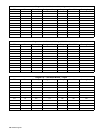

Program 1 −− .035 ER70S−3 Mild Steel −− Recommended Gases: Argon/CO

2

Gas: Argon/CO

2

mixes up to 10% CO

2

;

Argon/O

2

mixes up to 5% O

2

IPM Trim Peak Amp Background Amp Freq. Pulse Width Starting Amps

100 0 288 43 49 1.55 451

168 10 304 54 93 1.61 491

236 20 332 67 110 1.73 501

304 30 353 80 124 1.86 529

372 40 360 84 155 1.96 529

440 50 375 88 180 2.05 529

508 60 385 98 195 2.13 529

576 70 390 101 208 2.21 529

644 80 345 109 215 2.30 529

712 90 398 114 240 2.38 529

780 100 400 121 260 2.48 529