Optima

™

#043 389

A multipurpose,

microprocessor-based

pulse con trol for both

synergic MIG (wire

welding or GMAW) or

manual MIG pulsing.

Use this control with the

XMT 304/350 CC/CV

power sources and any Miller wire feeder,

including automatic feeders and spool

guns. Includes a 25 ft (7.6 m) cord with

14-pin plug. (Not for use with XMT 350

MPa or VS models.)

Extension Cords for Optima

#043 725 25 ft (7.6 m)

#043 726 50 ft (15.2 m)

#043 727 75 ft (22.9 m)

WC-24 Weld Control

#137 549

Designed for use with

Miller CV power sources

supplying 24 VAC and

14-pin recep tacles. For

use with Spoolmatic

30A spool gun.

WC-115A Weld Control

#137 546-01-1

Operates on 115 VAC

and is designed for

power sources without

a 14-pin receptacle. For

use with Spoolmatic 30A spool gun. Includes

10 ft (3 m) wall-type plug and power cord.

HF-251D-1

High-Frequency Arc

Starter and Stabilizer

#042 388

Portable 250 amp, 60%

duty cycle unit adds

high frequency to the

welding circuit to help start the arc when

using the DC TIG (GTAW) process.

Operates on 115 VAC, 50/50 Hz. See Lit.

Index No. AY/5.1.

Process Selector Control #042 872

Designed for use with dual wire feeders,

applications where electrical isolation and/or

polarity revers ing of weld current is required,

and for welding process changes. Includes

115 VAC/2 amp recepta cle, two 14-pin

receptacles and a 10 ft (3 m) 14-pin cord.

Gas Solenoid Kit #195 286

Easy to install, optional gas solenoid kit for

TIG welding applications. Kit only works

with XMT 350.

RFCS-14 Foot Control

#043 554

Heavy-duty foot current

and contactor control.

Includes 20 ft (6 m)

cord and 14-pin plug.

RHC-14 Hand Control

#129 340

Miniature hand control

for remote current and

contactor control.

Dimensions: 4 x 4 x

3-1/4 in (102 x 102 x 82 mm). Includes

20 ft (6 m) cord and 14-pin plug.

RMLS-14

#129 337

14-pin plug

Momentary- and maintained-contact rocker

switch for contactor control. Push forward for

maintained contact and back for momen tary

contact. Includes 20 ft (6 m) cord.

RCC-14 Remote Contactor and Current

Control #151 086

14-pin plug. Rotary-motion fingertip control

fastens to TIG torch using two Velcro

®

straps. Includes 28 ft (8.5 m) control cord.

RCCS-14 Remote Contactor and Current

Control #043 688

Up-and-down rotary-motion fingertip

control. Great for applications that require

a finer amperage control. Includes 28 ft

(8.5 m) control cord.

Extension Cords for Remote Controls

and 24 VAC Wire Feeders

#122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.8 m)

14-pin plug to 14-pin socket.

Note: Not for use with Optima or 60M Series.

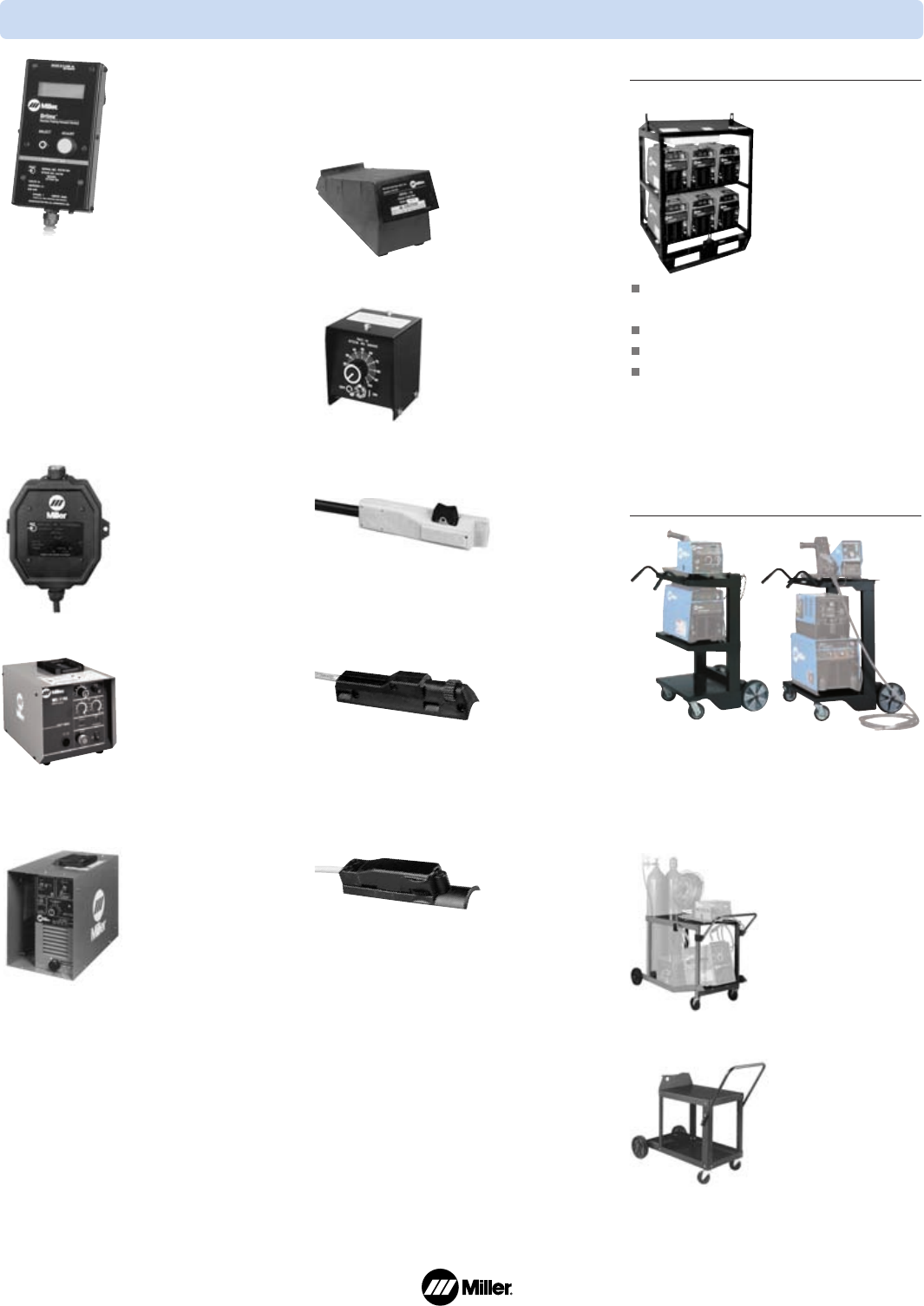

Inverter Racks

Four or Six-Arc Welding System

The Inverter Rack

conve niently houses

multiple XMT power

sources for multiple

welders. Both 4-pack

and 6-pack models

are available.

Features include:

Provision to parallel power sources or

common work connections

Two lifting eyes for transportation

Rugged skids for dragging or pushing

Customer can install up to a maximum

of 4 XMT 456 power sources

For detailed information on customized

Inverter Rack systems see Lit. Index No.

DC/18.81.

Running Gear

MIGRunner

™

Cart #195 445

MIGRunner

™

XL Cart #195 246

Small footprint and easily maneuverable,

with cylinder rack low enough that you do

not have to lift bottles.

XMT Cylinder Cart

#042 537

Carries two 160 lb

(72.6 kg) gas

cylinders, or one gas

cylinder and one

coolant system for

TIG (GTAW) welding.

Feeder mounts to tray above power source.

Universal Carrying

Cart and Cylinder

Rack #042 934

Holds power source,

and gas cylinder up

to 56 in (142.2 cm)

high mea sur ing

6 to 9 in (15.2 to 22.8 cm) in dia meter.

6

Genuine Miller Accessories

XL Cart

Regular

Cart