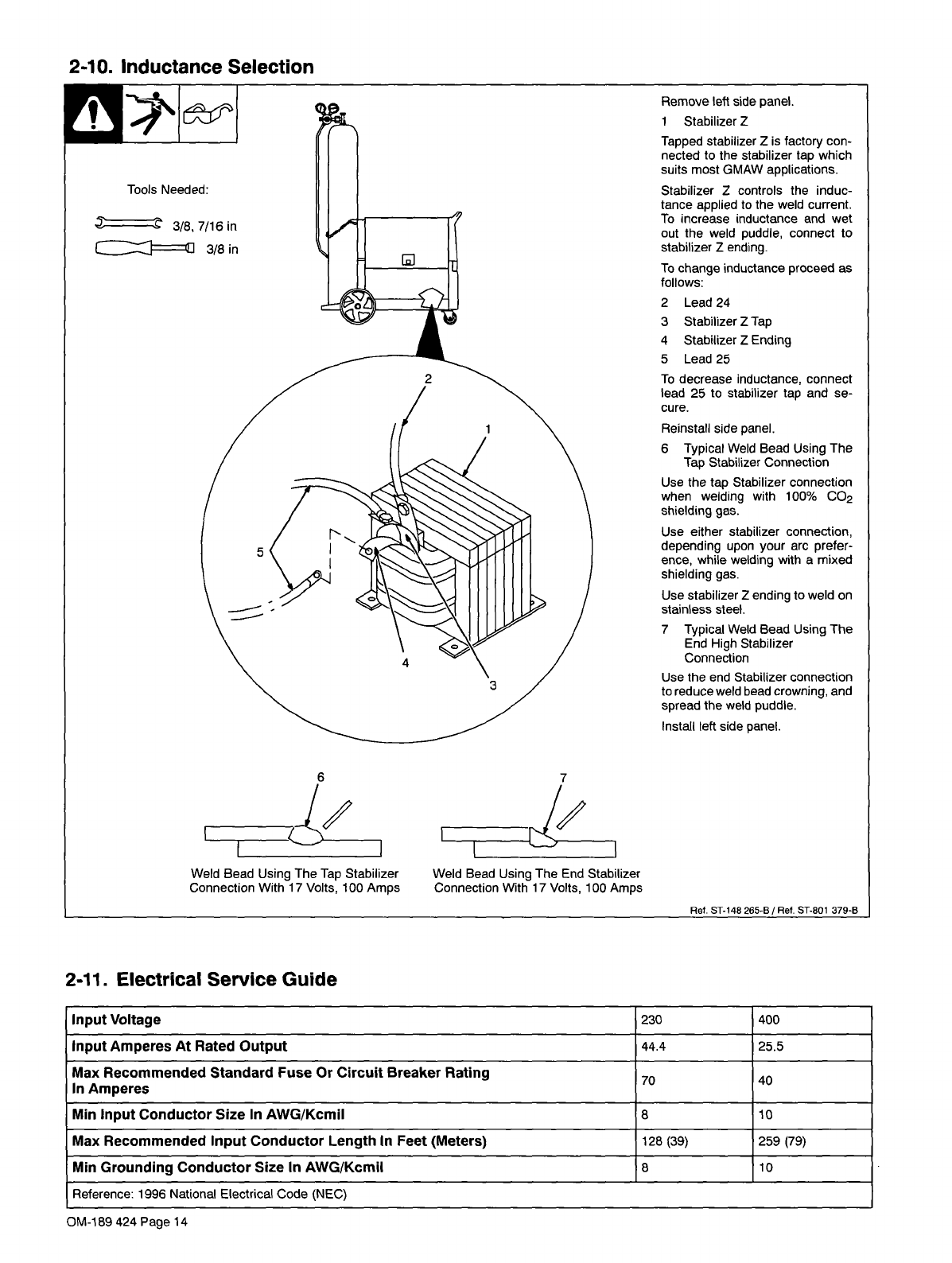

2-10.

Inductance

Selection

H

Weld

Bead

Using

The

Tap

Stabilizer

Connection

With

17

Volts,

100

Amps

II

Weld

Bead

Using

The

End

Stabilizer

Connection

With

17

Volts,

100

Amps

Remove

left

side

panel.

1

Stabilizer

Z

Tapped

stabilizer

Z

is

factory

con

nected

to

the

stabilizer

tap

which

suits

most

GMAW

applications.

Stabilizer

Z

controls

the

induc

tance

applied

to

the

weld

current.

To

increase

inductance

and

wet

out

the

weld

puddle,

connect

to

stabilizer

Z

ending.

To

change

inductance

proceed

as

follows:

2

Lead

24

3

Stabilizer

Z

Tap

4

Stabilizer

Z

Ending

5

Lead

25

To

decrease

inductance,

lead

25

to

stabilizer

tap

cure.

Reinstall

side

panel.

6

Typical

Weld

Bead

Using

The

Tap

Stabilizer

Connection

Use

the

tap

Stabilizer

connection

when

welding

with

100%

CO2

shielding

gas.

Use

either

stabilizer

connection,

depending

upon

your

arc

prefer

ence,

while

welding

with

a

mixed

shielding

gas.

Use

stabilizer

Z

ending

to

weld

on

stainless

steel.

7

Typical

Weld

Bead

Using

The

End

High

Stabilizer

Connection

Use

the

end

Stabilizer

connection

to

reduce

weld

bead

crowning,

and

spread

the

weld

puddle.

Install

left

side

panel.

2-11.

Electrical

Service

Guide

Input

Voltage

230

400

Input

Amperes

At

Rated

Output

44.4

25.5

Max

Recommended

Standard

Fuse

Or

Circuit

Breaker

Rating

In

Amperes

70

40

Mm

Input

Conductor

Size

In

AWG/KcmiI

8

10

Max

Recommended

Input

Conductor

Length

In

Feet

(Meters)

128

(39)

259

(79)

Mm

Grounding

Conductor

Size

In

AWG/KcmiI

8

10

Reference:

1996

National

Electrical

Code

(NEC)

Tools

Needed:

~

Z

3/8,7/l6in

~ZJiJ

3/8

in

connect

and

Se-

Rel.

5T-148

265-B

I

Ref.

ST.801

379-B

OM-189

424

Page

14