OM-211 076 Page 21

5-9. Process Set Up Push Button

• Press the Process Set Up push button the

first time will illuminate the button LED and

Process LED above the button. Both

displays will show the current process and,

if desired, these displays will be active to

allow selecting a new process. Default

processes are MIG, PULSE, and ACCU

PULSE.

• Pressing the Process Set Up push button a

second time will illuminate the Wire Type

LED and the bottom display will show wire

types available for the selected process. To

make a selection, rotate the Adjust control.

• Pressing the Process Set Up push button a

third time will keep Wire Type LED lit, but the

upper display will be active and show wire

sizes available for the current wire type. To

make a selection, rotate the Adjust control.

• Pressing the Process Set Up push button a

fourth time will illuminate the Gas Type LED

and both displays will show available gas

selections for the process, and wire type

and wire size selection. To select an item,

rotate the Adjust control.

• Pressing the Process Set Up push button a

fifth time will load the program that matches

the selected parameters (process, wire

type, wire size, gas). The upper display will

show PROG and the lower display will show

LOAD.

If no changes were made to any setup items,

no program will be loaded, and unit will return

to standby mode.

If a custom program is loaded using an

optional PDA with File Management software,

the upper display will show CUST and the

lower display will show PROG. The Adjust

control remains active to allow loading a

standard program in place of the custom

program.

• Pressing and holding the Process Set Up

push button in on power up allows viewing

the software revisions of each circuit board

in the system. The top display shows the

board (PCM, UIM, WFCM, and AIM (auto-

mated units only) and the lower display

shows the last 3 digits of the circuit board

part number plus a letter designator. Press

the flashing Feeder Set Up push button to

exit the screen displays and continue the

power up process.

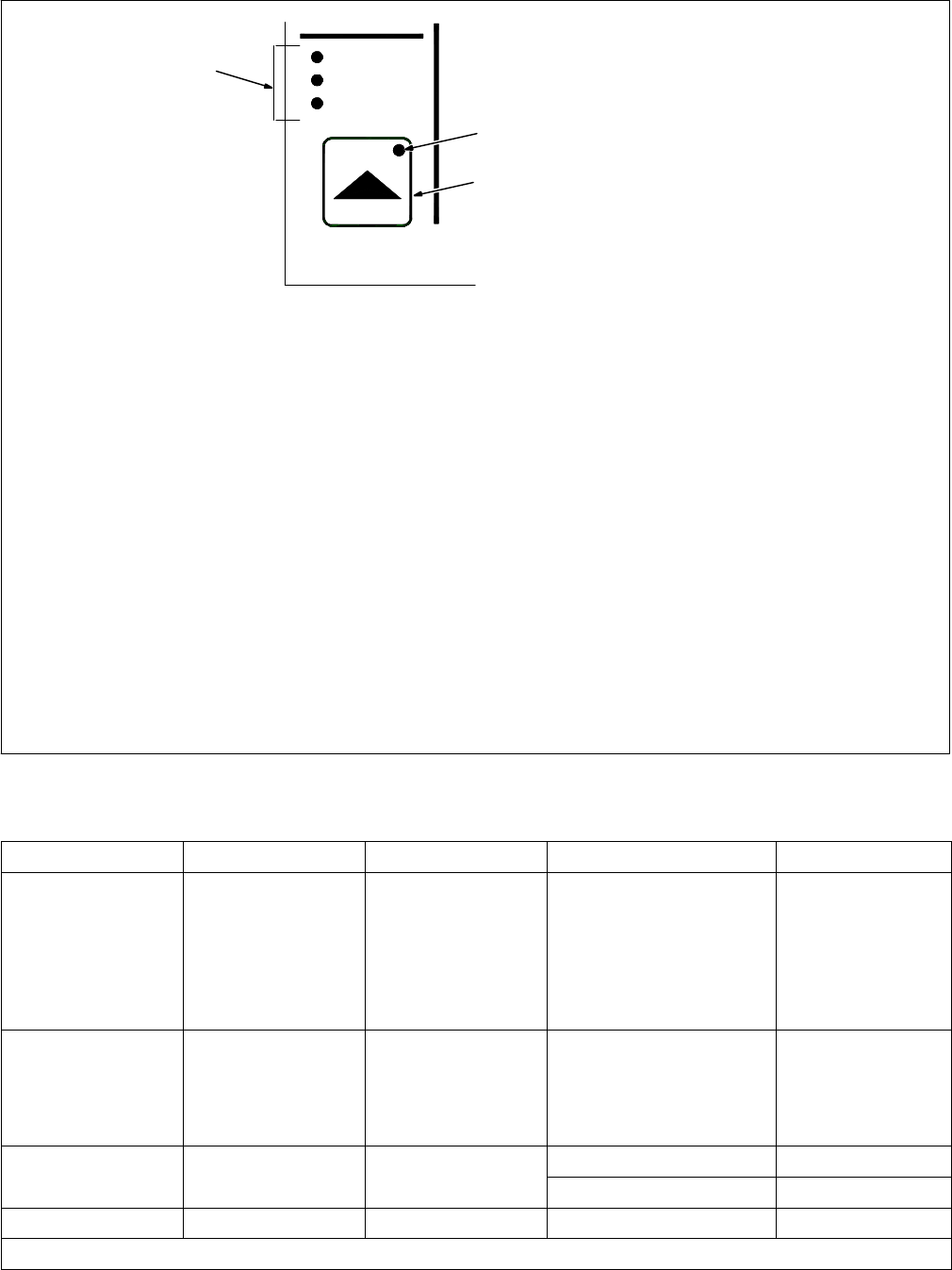

1

3

2

1 Process Set Up Push Button

2 Process Set Up LED

3 Program Selection LEDs

Process

Wire Type

Gas Type

Process Set Up

Table 5-1. Welding Wire And Gas Abbreviations*

Wire Description Wire Abbreviation Alloy Type Gas Type Gas Abbreviation

Steel STL E70, E100, E120 100% CO

2

,

90% Argon/10% CO

2

,

85% Argon/15% CO

2

,

75% Argon/25% CO

2

,

95% Argon/5% CO

2

,

95% Argon /5% O

2

,

98% Argon/2% O

2

CO2

C10

C15

C25

C5

OX5

OX2

Stainless Steel SS 308, 309, 312, 316 98% Argon, 2% O

2

(81Ar/18HE/1CO

2

Accu-pulse)

90HE/7-1/2Ar/2-1/2CO

2

MIG/RMD/Accu-pulse)

OX2

Tri Gas

Tri Gas

Cored Tubular Wire MCOR 71, 76, 86R, 409,

439

90% Argon/10% CO

2

C10

439

98% Argon/2% O

2

OX2

Aluminum ALUM 4XXX, 5XXX 100% Argon ARGN

* Not all wire types may be available with your unit.