OM-4421 Page 46

Trouble Remedy

No remote fine amperage control. Repair or replace remote control device.

Have Factory Authorized Service Agent check OCV control circuit.

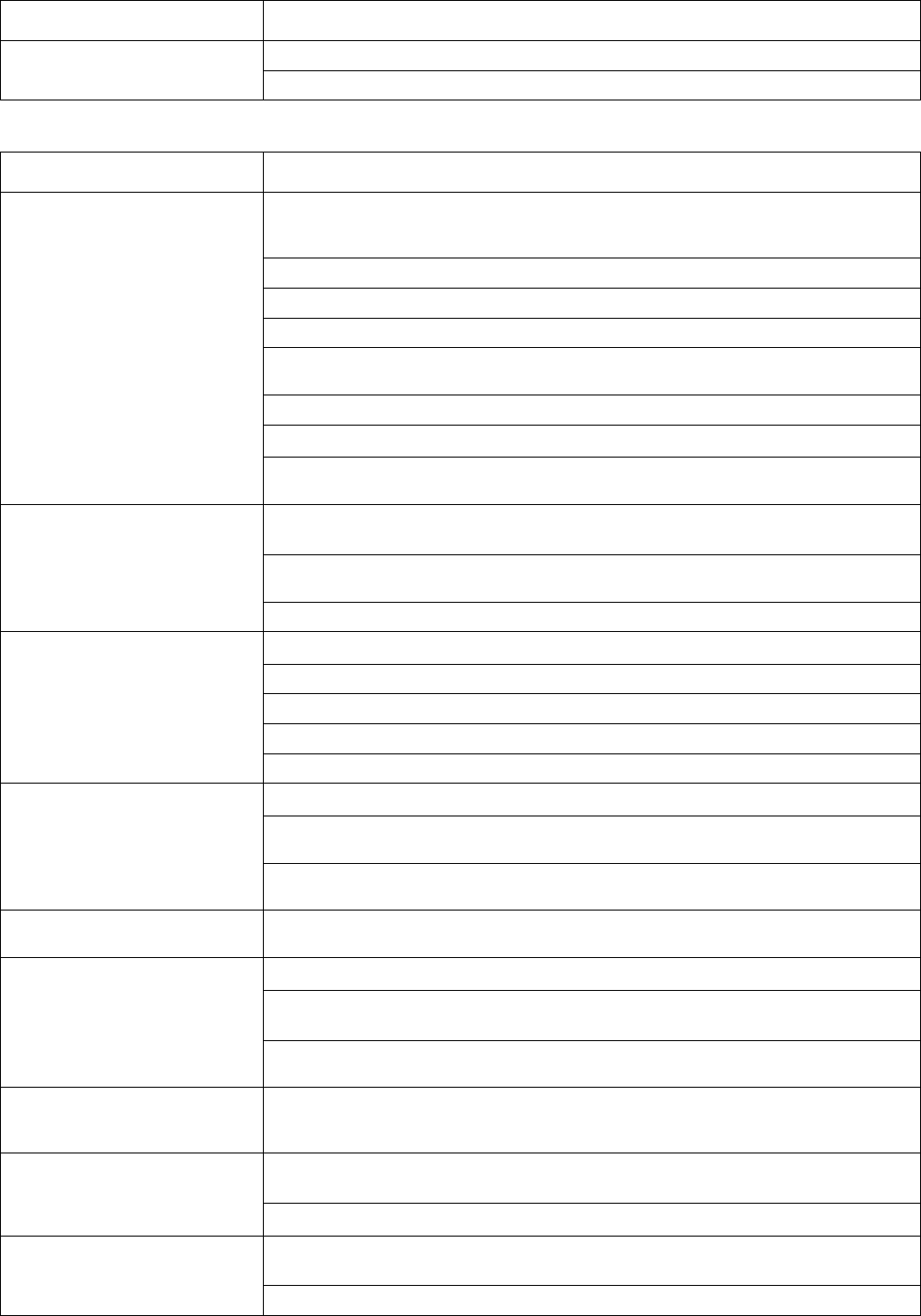

B. Welding − CC/CV Models

Trouble Remedy

No weld output; generator power output

okay at ac receptacles.

Place Process/Contactor switch in a Weld Terminals Always On position, or place switch in a Remote

On/Off Switch Required position and connect remote contactor to optional Remote 14 receptacle RC14

(see Sections 5-11 and 7-1).

Check position of Ampere Range switch.

Check position of optional Polarity switch or Polarity/AC switch.

Reset supplementary protector CB11 (see Section 9-8).

Reset supplementary protector CB5 (see Section 9-8). Check for faulty remote device connected to

RC14.

Check and secure connections to Remote 14 receptacle RC14 (see Section 5-11).

Have Factory Authorized Service Agent check connector board PC6 and connections.

Check fuse F2, and replace if open (see Section 9-8). Have Factory Authorized Service Agent check

brushes and slip rings, weld excitation circuit, field current regulator board PC1, and the rotor.

No weld output or generator power out-

put at ac receptacles.

Disconnect equipment from generator power receptacles during start-up.

Check fuses F1 and F2, and replace if open (see Section 9-8). Have Factory Authorized Service Agent

check integrated rectifier SR1, capacitor C9, field current regulator board PC1, and the rotor.

Have Factory Authorized Service Agent check brushes and slip rings, and field excitation circuit.

Erratic weld output. Check and tighten connections inside and outside unit.

Be sure connection to work piece is clean and tight.

Use dry, properly stored electrodes.

Remove excessive coils from weld cables.

Have Factory Authorized Service Agent check brushes and slip rings.

High weld output. Check position of Ampere Range switch and Voltage/Amperage Adjust control.

Check engine speed, and have engine manufacturer’s factory authorized service agent adjust if nec-

essary. See Section 9-6 for idle speed adjustment.

Have Factory Authorized Service Agent check field current regulator board PC1, and PC1 voltage feed-

back circuit.

Voltage/Amperage control does not

work when welding in Stick mode.

Place Ampere Range switch in lower range. Voltage/Amperage control does not work with Ampere

Range switch in highest range.

Low weld output. Check position of Ampere Range switch and Voltage/Amperage Adjust control.

Check engine speed, and have engine manufacturer’s factory authorized service agent adjust if neces-

sary. See Section 9-6 for idle speed adjustment.

Check fuses F1 and F2, and replace if open (see Section 9-8). Have Factory Authorized Service Agent

check integrated rectifier SR1, capacitor C9, field current regulator board PC1, and the rotor.

Electrode sticks to the workpiece more

frequently during low voltage (short arc

length) conditions.

Circuit breaker CB4 may be open. CB4 automatically resets when the fault is corrected (see Section 9-8).

Have Factory Authorized Service Agent check transformer T1 and integrated rectifiers SR4 and SR5.

Low open-circuit voltage. Check engine speed, and have engine manufacturer’s factory authorized service agent adjust if neces-

sary. See Section 9-6 for idle speed adjustment.

Check position of Process/Contactor switch.

No remote fine amperage or voltage

control.

Place Voltage/Amperage Adjust switch in Remote position.

Check and secure connections to Remote 14 receptacle RC14 (see Section 5-11).