OM-1600 Page 6

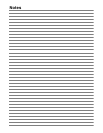

B. Connecting Torch With Two-Piece Cable

803 664-A

Y Turn Off welding power

source power before install-

ing torch.

Obtain the following hose:

1 Gas Hose With 5/8-18 Right-

Hand Fittings

Connections:

2 Regulator/Flowmeter

3 Gas Cylinder

4 Welding Power Source

5 Torch Gas-In Hose

6 Torch Power Cable

7 Work Clamp

Connect work clamp to a clean,

paint-free location on workpiece,

close to weld area.

Use wire brush to clean weld joint

area.

8 Foot Control

9 Gas Valve

Valve controls gas preflow and

postflow. Open valve on torch just

before welding.

Preflow is used to purge the imme-

diate weld area of atomsphere.

Postflow is required to cool tung-

sten and weld, and to prevent con-

tamination of tungsten and weld. Af-

ter welding, leave valve open about

1 second for every 10 amperes of

weld current. Close valve on torch

when postflow is finished.

If applicable, install high-frequency unit.

Tools Needed:

5/8, 7/8 in

Torch With Gas Valve

9

5

6

7

4

2

3

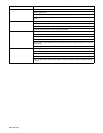

Torch Without Gas Valve

4

2

3

1

6

7

8

5

803 314

−

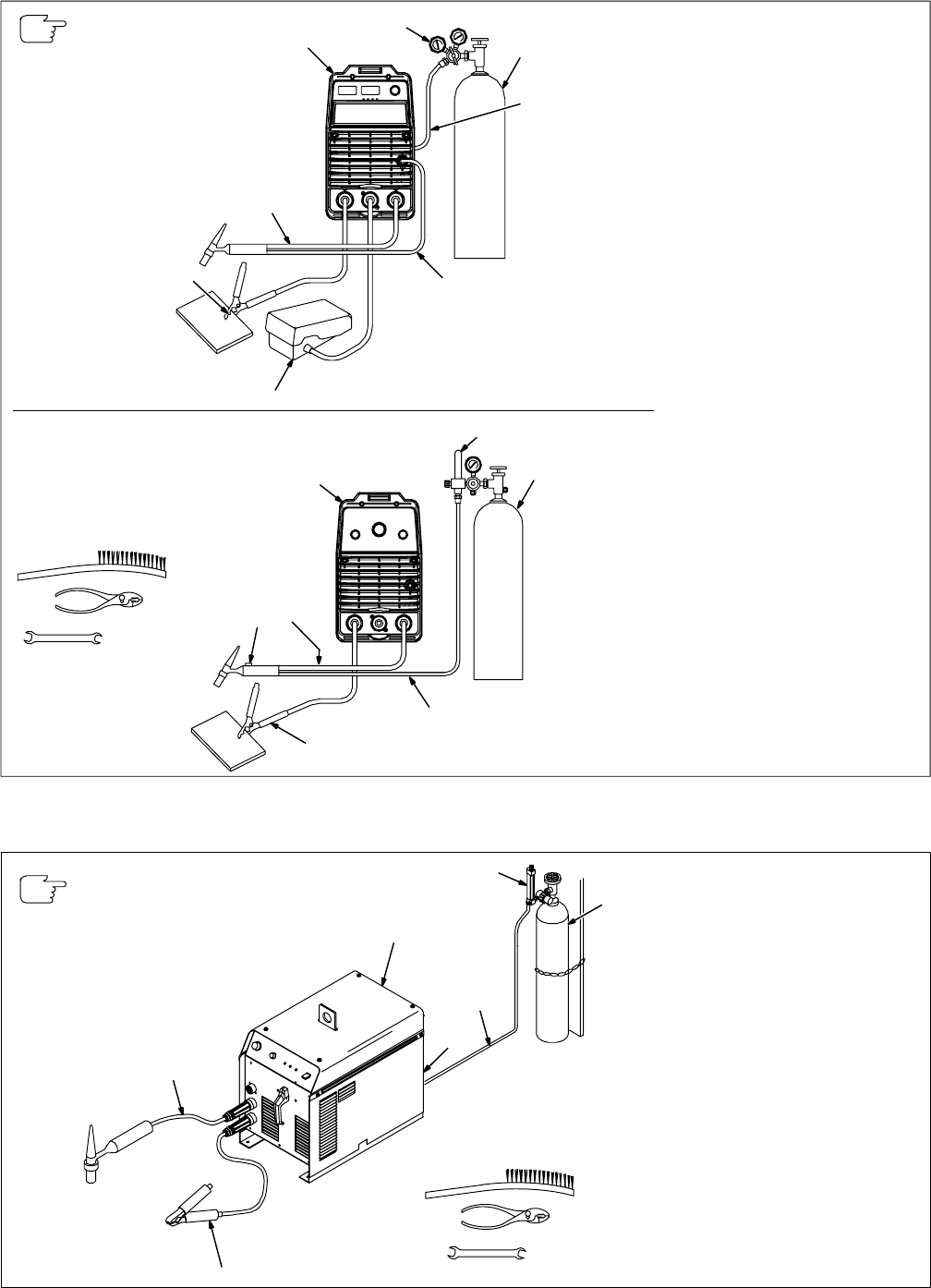

C. Connecting Torch With Flow-Through Type Connection

Y Turn Off welding power

source power before install-

ing torch.

Obtain the following hose:

1 Gas Hose With 5/8-18 Right-

Hand Fittings

Connections:

2 Regulator/Flowmeter

3 Gas Cylinder

4 Welding Power Source

5 Gas Valve

6 One-Piece Torch Cable

7 Work Clamp

Connect work clamp to clean, paint-

free location on workpiece, close to

weld area.

Use wire brush to clean metal at

weld joint area.

Ref. ST-802 540-A

If applicable, install high-frequency unit.

Tools Needed:

5/8, 7/8 in

1

2

3

4

5

6

7

Torch Without Gas Valve