2

Big 40

®

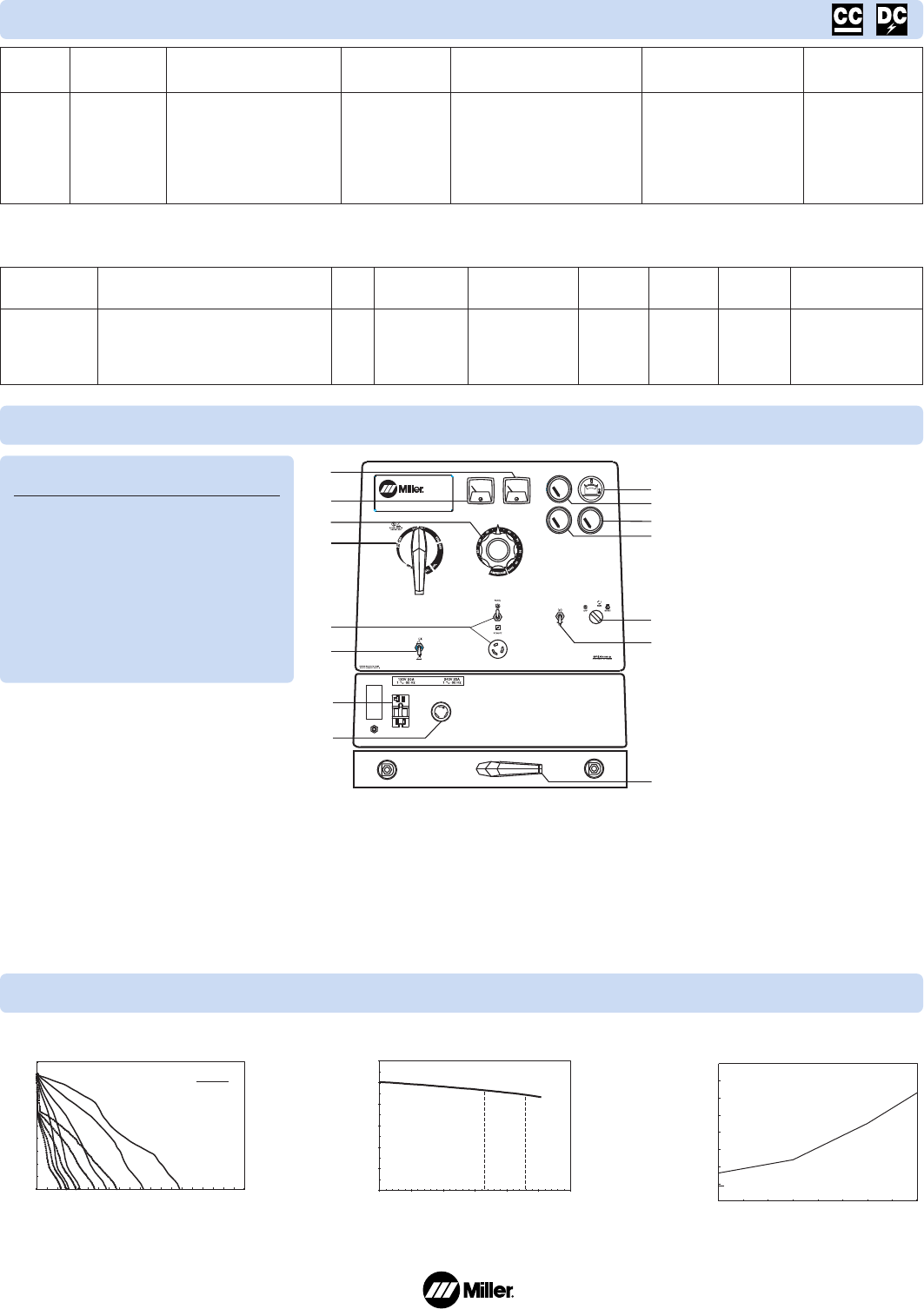

Diesel CC Control Panel

Welding

Mode

CC/DC

Big 40

®

Diesel CC Specifications

(Subject to change without notice.)

Max. Open-

Circuit Voltage

95

Weld Output

Range

55–500 A

Weld Output Rated

at 104˚F (40˚C)

400 A at 36 VDC (14.4 kW),

100% Duty Cycle

450 A at 38 VDC (17.1 kW),

60% Duty Cycle

500 A at 30 VDC (15 kW),

40% Duty Cycle

Generator Output Rated

at 104˚F (40˚C)

Peak: 5500 watts

Continuous: 4000 watts,

34/17 A, 120/ 240 VAC, 60 Hz

while welding

Net Weight

(without fuel)**

1540 lb (697 kg)

Dimensions*

H: 43 in (1092 mm)

W: 28-1/2 in (724 mm)

D: 64-7/16 in (1637 mm)

NEMA EWI (ANSI C87.1) Class (1) output ratings. *Additional 7 in (178 mm) to top of exhaust. **Additional 190 lb (86 kg) when fuel tank is full.

Big 40

®

Diesel CC Performance Data

100

80

60

40

20

0

0 100 200 300 400 500 600 700 800 900 1000

DC AMPERES

DC VOLTS

Ranges

170 – 365

230 – Max

110 – 225

55 – 85

70 – 130

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

0 50 100 150 200 250 300 350 400

DC WELD AMPERES

AT 100% DUTY CYCLE

US Gal./Hr.

0.00

0.95

1.89

2.84

3.79

4.73

5.68

6.62

7.57

US Liters/Hr.

IDLE

CC/DC VOLT/AMP CURVES FUEL CONSUMPTION CURVE

4 kW

5.5 kW

302520151050

6050403020100

AC AMPERES IN 240 V MODE

AC AMPERES IN 120 V MODE

50

0

100

150

200

250

300

AC VOLTS

0

25

50

75

100

150

125

GENERATOR POWER CURVE

Engine

Brand

CATERPILLAR

Tier IVi,

C2.2 Diesel

HP

32.6

Type

Four-cylinder,

industrial,

liquid-cooled

diesel

Engine

Speeds

Run: 1850 RPM

Idle: 1250 RPM

Fuel

Capacity

25 gal

(95 L)

Coolant

Capacity

9 qt

(8.5 L)

Automatic Engine

Shutdown

Oil Pressure

Coolant Temperature

Oil

Capacity

9 qt

(8.5 L)

Features

Tier IVi, EPA-certified, indirect-injected,

liquid-cooled diesel engine. Right-side

service access with service intervals of

500 hours for oil and filters.

Engine Specifications (Subject to change without notice.)

9

10

12

11

13

14

15

4

6

3

1

2

5

7

8

Additional Features

Proven, rugged rheostat control technology

that has been in Miller engine drives for

over 60 years. Contains no printed control

boards.

Provisions are provided to plug a

RHC3GD34A remote control that will allow

precise adjustment of amperage without

walking back to the machine.

1. DC Ammeter*

2. DC Voltmeter*

3. Amperage Adjust Control

4. Amperage Range Switch

5. Amperage Adjust Switch and

Remote Amperage Adjust Receptacle

6. Stick/TIG Selector Switch

7. 120 VAC, 20 A GFCI Duplex Receptacle

8. 240 VAC, 30 A TwistLock Receptacle

(NEMA L6-30)

9. Fuel Gauge/Hour Meter/Oil Change Interval/

Engine Shutdown Indicator

10. Engine Oil Pressure Gauge

11. Battery Voltmeter*

12. Engine Coolant Temperature Gauge

13. Engine Control Switch

14. Starting Aid Switch

15. Polarity Switch*

*Optional on select models.