To select a generator that has enough power output in watts, add the watts

for the items you want to simultaneously run. Tools and appliances with

induction motors may require 3–7 times the listed wattage when starting.

All data listed is approximate—check your tool/appliance for specific

wattage requirements.

Bobcat 3 Phase will easily start and run the following equipment:

TYPICAL EQUIPMENT POWER USAGE

Equipment

Pivot Irrigation (9–1 HP), 9 Tower

Pivot Irrigation (6-3/4 HP, 3–1-3/4 HP, 1–1 HP),

8 Tower with Corner Arm

Starting Watts Running Watts

Barn Cleaner (5 HP) 11,600 3000

Silo Unloader (5 HP) 12,200 4300

Portable Conveyor (1/2 HP) 3400 1000

Milker (5 HP) 10,500 2800

Hand Drill (1/2 inch) 600 600

Circular Saw (8-1/4 inch) 1400 1400

Air Compressor (1-1/2 HP) 8200 2200

Flood Lights (Vapor) 1250 1000

Refrigerator/Freezer 2200 700

Sump Pump 1300 800

Millermatic

®

212 MIG Welder 6500 6500

(30–210, 230 V)

Spectrum

®

625 6900 6900

(30 A, 230 V, 1/2 in cut)

The Bobcat Generator Power Advantage

Tools and motors are designed to operate within 10% of

120/240/480 VAC. The Bobcat’s power generator provides strong

power while keeping the voltage within 10% of 120/240/480 VAC.

This increases tool/motor performance and life.

Accu-Rated

™

– Not Inflated Generator Power

Miller’s Accu-Rated

™

11,000 watts of

usable

peak power is delivered for a

minimum of 30 seconds. Accu-Rated means peak power is usable for

maximum generator loads such as plasma cutting, Millermatics and motor

starting. Accu-Rated peak power beats the competition’s very short-duration

peak or surge power. Use your peak power, it’s more than a number.

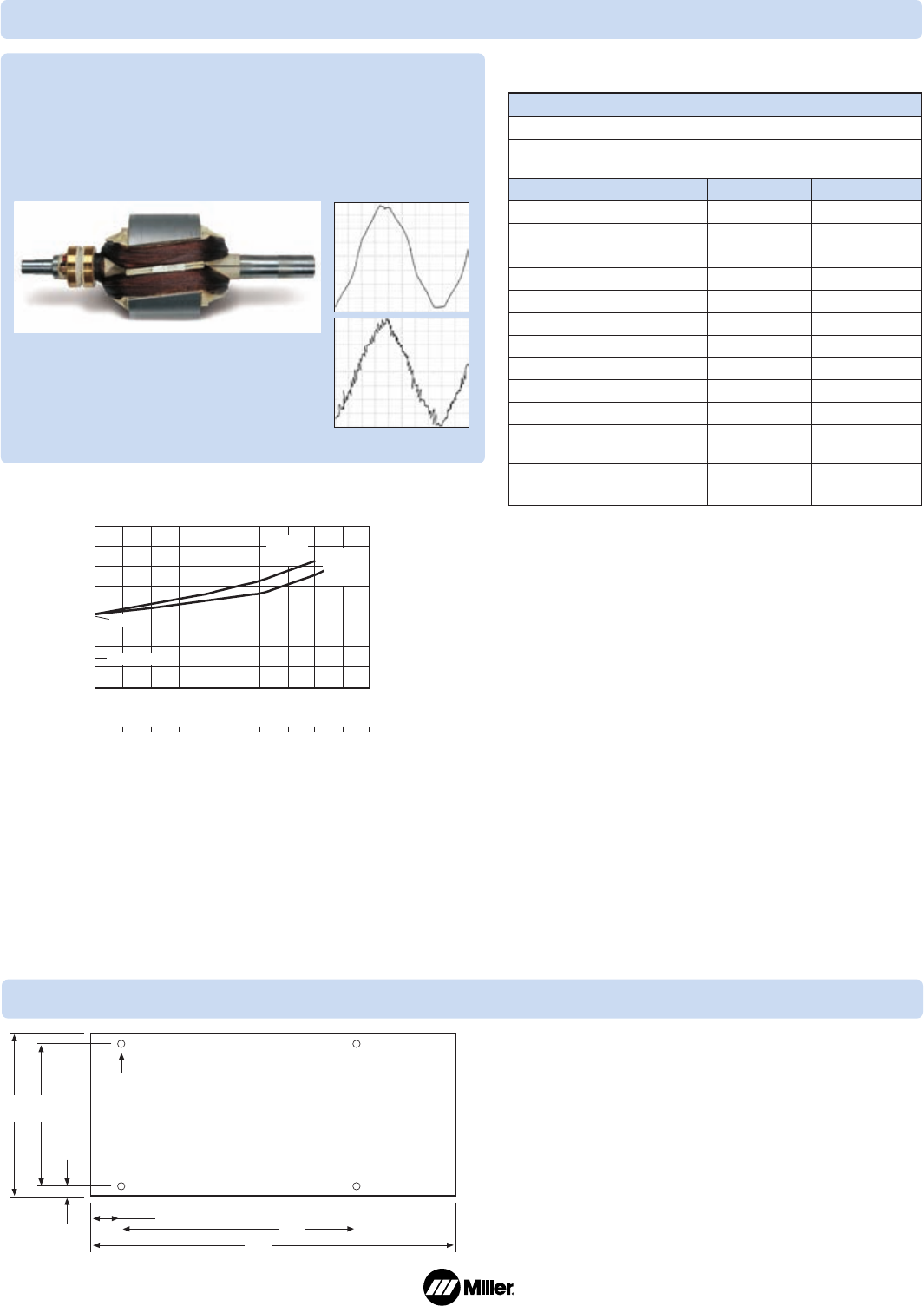

Smooth Power – Not Spike Power

Revolutionary ten-degree skewed-rotor design

optimizes generator performance for smoother

power—not spiked power found with other

brands. Better power—better performance.

Fuel Consumption Data

• 12-gallon fuel capacity.

• On a typical job using 1/8-in 7018 electrodes (125 amps, 20% duty cycle)

expect about 20 hours of operation.

• Welding at 150 amps at 40% duty cycle uses approxi mately 3/4 gallon

per hour— about 16 hours of operation.

• Under a continuous load of 4000 watts of generator power, the Bobcat

would run for about 14 hours.

IDLE 2200 RPM

3750 RPM

1-Phase

Generator

Power

DC WELD/

3-Phase

Generator

Power

FUEL CONSUMPTION

(Kohler 23 HP Command OHV)

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

0

U.S. GAL/HR

0 25 50 75 100 125 150 175 200 225 250

WELD AMPS AT 100% DUTY CYCLE

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

POWER KVA AT 100% DUTY CYCLE

Waveform Comparison

Bobcat

Competitor

3

A. 20 in (508 mm)

B. 16-1/2 in (419 mm)

C. 1-3/4 in (44 mm)

D. 6-1/16 in (154 mm)

E. 32-3/4 in (832 mm)

F. 45-3/8 in (1153 mm) (Gas)

G. 13/32 in (10 mm) diameter

Height: 33-1/2 in (851 mm)

(to top of exhaust)

Width: 20 in (508 mm)

Depth: 45-7/8 in (1164 mm)

4 Holes

Engine End

G

A

B

C

D

E

F

Mounting Specifications