OM-206 Page 24

SECTION 7 – SELECTING AND PREPARING

TUNGSTEN ELECTRODE

gtaw 7/97

For additional information, see your distributor for a handbook on the Gas

Tungsten Arc Welding (GTAW) process.Wear clean gloves to prevent

contamination of tungsten electrode.

NOTE

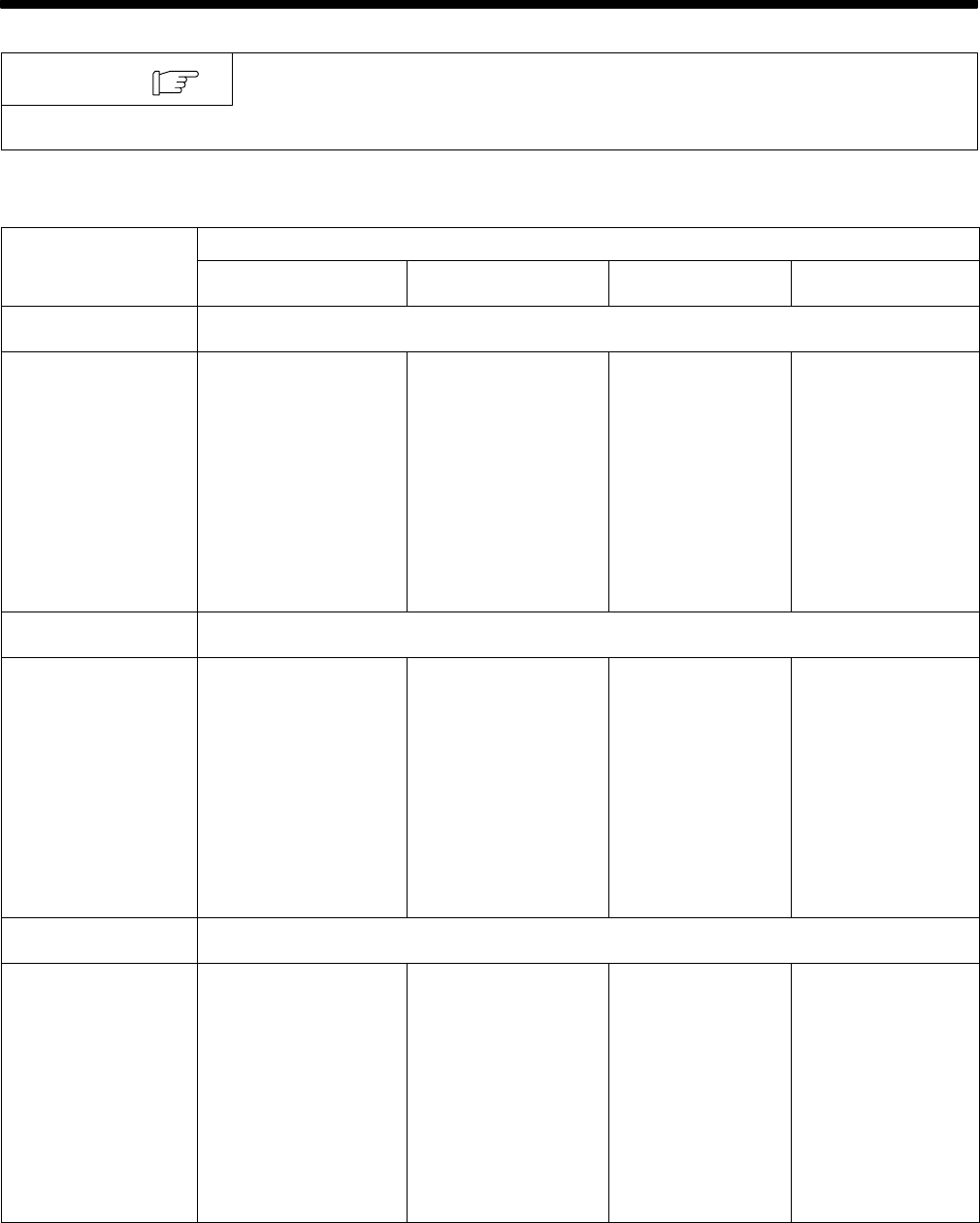

7-1. Selecting Tungsten Electrode

Amperage Range - Gas Type♦ - Polarity

Electrode Diameter DC – Argon – Electrode

Negative/Straight Polarity

DC – Argon – Electrode

Positive/Reverse Polarity

AC – Argon – Using

High Frequency

AC – Argon – Balanced

Wave Using High Freq.

Pure Tungsten

(Green Band)

.010” Up to 15 * Up to 15 Up to 10

.020” 5-20 * 5-20 10-20

.040” 15-80 * 10-60 20-30

1/16” 70-150 10-20 50-100 30-80

3/32” 125-225 15-30 100-160 60-130

1/8” 225-360 25-40 150-210 100-180

5/32” 360-450 40-55 200-275 160-240

3/16” 450-720 55-80 250-350 190-300

1/4” 720-950 80-125 325-450 250-400

2% Thorium Alloyed

Tungsten (Red Band)

.010” Up to 25 * Up to 20 Up to 15

.020” 15-40 * 15-35 5-20

.040” 25-85 * 20-80 20-60

1/16” 50-160 10-20 50-150 60-120

3/32” 135-235 15-30 130-250 100-180

1/8” 250-400 25-40 225-360 160-250

5/32” 400-500 40-55 300-450 200-320

3/16” 500-750 55-80 400-500 290-390

1/4” 750-1000 80-125 600-800 340-525

Zirconium Alloyed Tung-

sten (Brown Band)

.010” * * Up to 20 Up to 15

.020” * * 15-35 5-20

.040” * * 20-80 20-60

1/16” * * 50-150 60-120

3/32” * * 130-250 100-180

1/8” * * 225-360 160-250

5/32” * * 300-450 200-320

3/16” * * 400-550 290-390

1/4” * * 600-800 340-525

♦Typical argon shielding gas flow rates are 15 to 35 cfh (cubic feet per hour).

*Not Recommended.

The figures listed are intended as a guide and are a composite of recommendations from American Welding Society (AWS) and electrode

manufacturers.