OM-1102 Page 2

2-1. DESCRIPTION

The SWINGPAK-12 and SWINGPAK-16 provide a di-

rect mounting facility for several welding power sources

(refer to welding power source Owner’s Manual for base

mounting hole layout), SWINGARC wire feeder or CB

boom, RADIATOR 1A or RADIATOR 2A coolant sys-

tem, MPG-395B resistance grid, AFT-100 flux tank, and

shielding gas cylinder. If equipment other than that listed

is to be used, mounting hole locations may have to be

modified to accommodate equipment. A SWINGPAK

locker and brackets for mounting a disconnect switch to

the SWINGARC post support are also supplied.

Additional space is available on the base for mounting

customer supplied accessories.

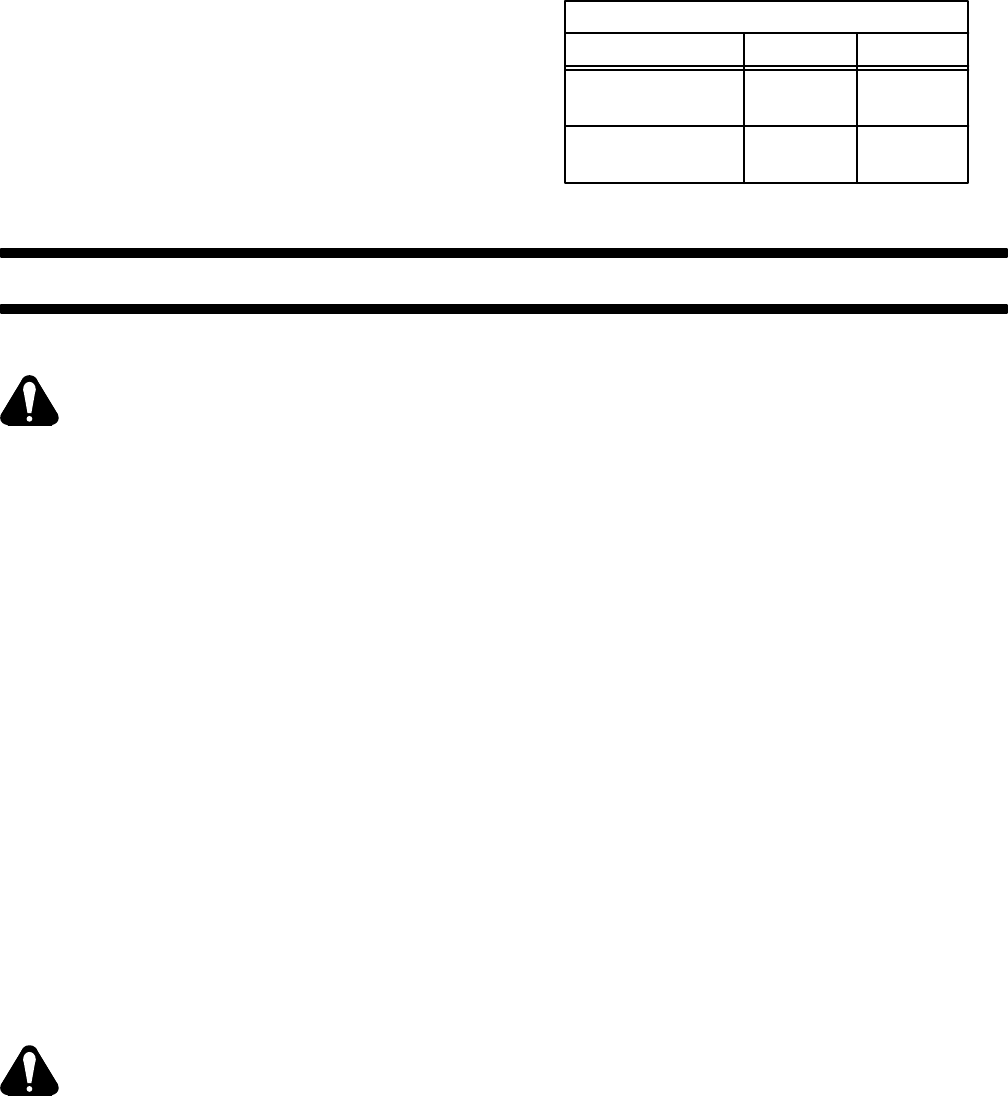

Table 2-1. Specifications

Weight

Net Ship

SWINGPAK-12

SWINGPAK-16

412 lbs.

(187 kg)

504 lbs.

(229 kg)

418 lbs.

(190 kg)

510 lbs.

(231 kg)

SECTION 3 – INSTALLATION OR RELOCATION

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Disconnect equipment input power conduc-

tors from deenergized supply line BEFORE

moving unit.

3-1. LOCATION

When installing this unit, be sure to allow room for the

boom to swing horizontally in the desired arc, and to piv-

ot upward to the desired angle. The location should al-

low room to remove panels of associated equipment for

installation, inspection, maintenance, and repair proce-

dures. Consider the input power requirements as well as

coolant (water) needs of optional equipment when

choosing a location.

The service life and efficiency of this unit and associated

equipment will be reduced if they are subjected to high

levels of dust, dirt, moisture, corrosive vapors, and ex-

treme heat.

Mounting holes are provided in the SWINGPAK base for

installing equipment.

3-2. INSTALLATION (Figures 2-1 And 4-1)

WARNING: OVERTURNING BASE can result

in serious injury and equipment damage.

• Mount the welding power source on SWING-

PAK base before mounting SWINGARC wire

feeder into SWINGARC support base.

• Do not install or operate on an incline.

• Do not lift the SWINGPAK base with a fork lift

from the sides unless the lift forks extend far

enough under the base to ensure against tip-

ping.

IMPROPER LIFTING OR INSTALLING OF

EQUIPMENT can cause personal injury and

equipment damage.

• Use equipment of adequate capacity to lift

components.

• Use bolts and fasteners of adequate capacity

to assemble and install unit.

IMPORTANT: Refer to Figures 2-1 and 4-1 during as-

sembly as necessary.

Mounting hardware is packed in locker for shipping pur-

poses. Remove hardware kit from locker and proceed

as follows:

1. Install boom support base onto SWINGPAK base

using supplied 1/2-13 x 1-1/2 inch cap screws

(Item 23, Figure 4-1) and associated hardware

(see Figure 2-1 for mounting location).

2. Locate appropriate mounting holes on SWING-

PAK base for welding power source, and install

power source onto SWINGPAK base using

supplied 3/8-16 x 1-1/4 inch cap screws (Item 20,

Figure 4-1).

3. Install boom into boom support base following

procedure outlined in appropriate Owner’s Manu-

al.

4. If applicable, install AFT-100 flux tank onto

SWINGPAK base using supplied 5/16-18 x 1 inch

cap screws (Item 13, Figure 4-1) and associated

hardware.

5. Install SWINGPAK locker onto SWINGPAK base

using supplied 1/4-20 x 3/4 inch self-threading

screws (item 16, Figure 4-1).

6. If applicable, install coolant system mounting

brackets onto SWINGPAK locker using supplied

1/4-20 x 1inch cap screws (Item 7, Figure 4-1).