OM-225 Page 15

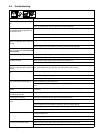

3-2. Sequence Of Operation

Put On Personal

Safety

Equipment

Install &

Connect

Equipment

EXAMPLE Of Cutting Operation

ST-801 400-A

Press trigger. Pilot arc starts.

Postflow continues for approx. 20 to 30

seconds after releasing trigger; cutting arc

can be instantly restarted during postflow

by pressing trigger.

Check Torch Tip,

Electrode, And

Retaining Cup

Check Gas/Air

Pressure

Set

Controls

Begin

Cutting

Turn On

Power Source

The pilot arc starts immediately when trigger is pressed. If cutting is

not established within 5 seconds after trigger is pressed, pilot arc

goes out and trigger must be released and pressed again.

Place drag shield on edge of metal, or allow

correct standoff distance – approximately 1/8

in (3 mm). For gouging, use 1/8 to 1/4 in (3 - 6

mm) standoff. Hold tip at about a 45° angle.

Be sure to use gouging consumables.

Do not clean torch by hitting it against a

hard surface. Hitting hard surfaces can

damage torch parts and stop proper opera-

tion.

Inspect shield cup, tip, and electrode for

wear before cutting or whenever cutting

speed has been significantly reduced (see

torch Owner’s Manual). Do not operate

torch without a tip or electrode in place.

After cutting arc starts, slowly

start moving torch across metal.

Adjust torch speed so

sparks go thru metal and

out bottom of cut.

Pause briefly at end of

cut before releasing trigger.

If arc goes out while cutting, the arc outage detction circuit will

automatically restart the arc. There is no need to manually retrigger

the torch. This is useful for cutting perforated metal.