OM-4422 Page 40

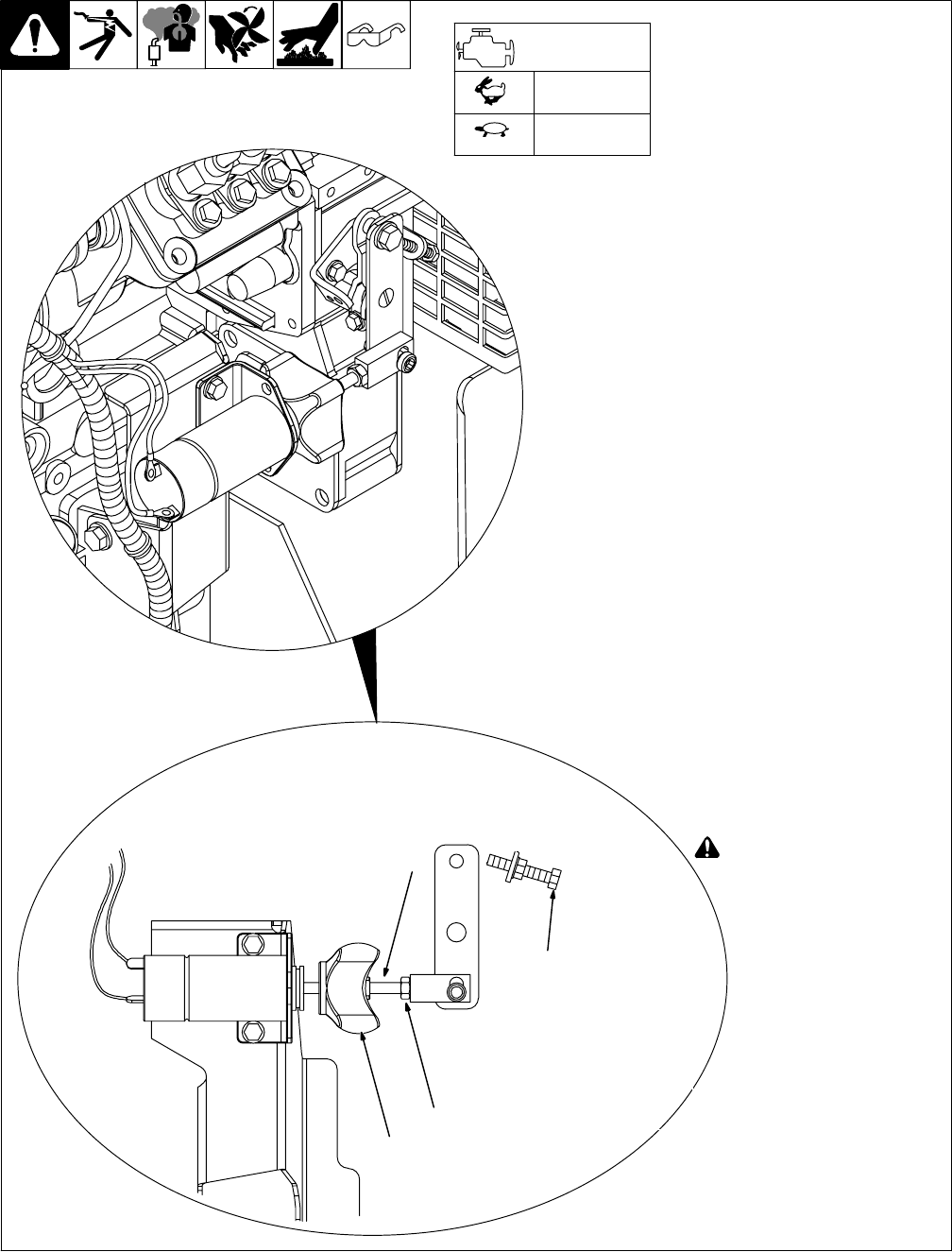

8-9. Adjusting Engine Speed On Models With Automatic Idle (Optional)

803 563-G

Engine Speed Adjustment

After tuning engine, check engine

speed with tachometer or frequen-

cy meter. See table for proper no

load speed. If necessary, adjust

speed as follows:

Start engine and run until warm.

Turn Process/Contactor switch to

Stick − Weld Terminals Always On

position.

1 Throttle Rod / Plunger

2 Lock Nut

3 Rubber Boot

4 Adjustment Screw

Adjustment screw is not used to ad-

just engine speed when automatic

idle option is installed. However, it

must be at least 1/8 in (3 mm) away

from the throttle arm when engine is

running at idle rpm.

Unhook rubber boot from the sole-

noid housing but leave connected

to plunger.

Loosen lock nut. Place Engine

Control Switch in Auto position.

Turn throttle rod and plunger until

engine runs at idle speed. Tighten

lock nut.

Hook rubber boot back onto sole-

noid housing.

. Be sure solenoid plunger pulls

all the way in (“bottoms”) when

energized.

Weld/Power Speed Adjustment

. Weld/power speed adjustment

must be done by the engine

manufacturer’s factory autho-

rized service agent.

Tampering with adjustments

other than shown may affect

engine warranty.

! Stop engine.

1

1880 rpm max

(62.6 Hz)

1500 rpm

(50 Hz)

Engine Speed

(No Load)

2

3

4

. To prevent solenoid

damage, be sure a 1/8

in (3 mm) gap exists be-

tween the engine low

speed screw and

throttle lever when the

solenoid is held in the

energized position.