OM-1546 Page 16

SECTION 4 – MAINTENANCE & TROUBLESHOOTING

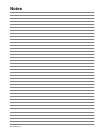

4-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months

Replace

Unreadable

Labels

Clean And

Tighten

Weld

Terminals

Repair Or

Replace

Cracked

Weld Cable

Gas HoseGun Cable

Replace

Cracked

Parts

6 Months

Blow Out Or Vacuum

Inside,

During Heavy Service,

Clean Monthly

OR

Clean

Drive

Rolls

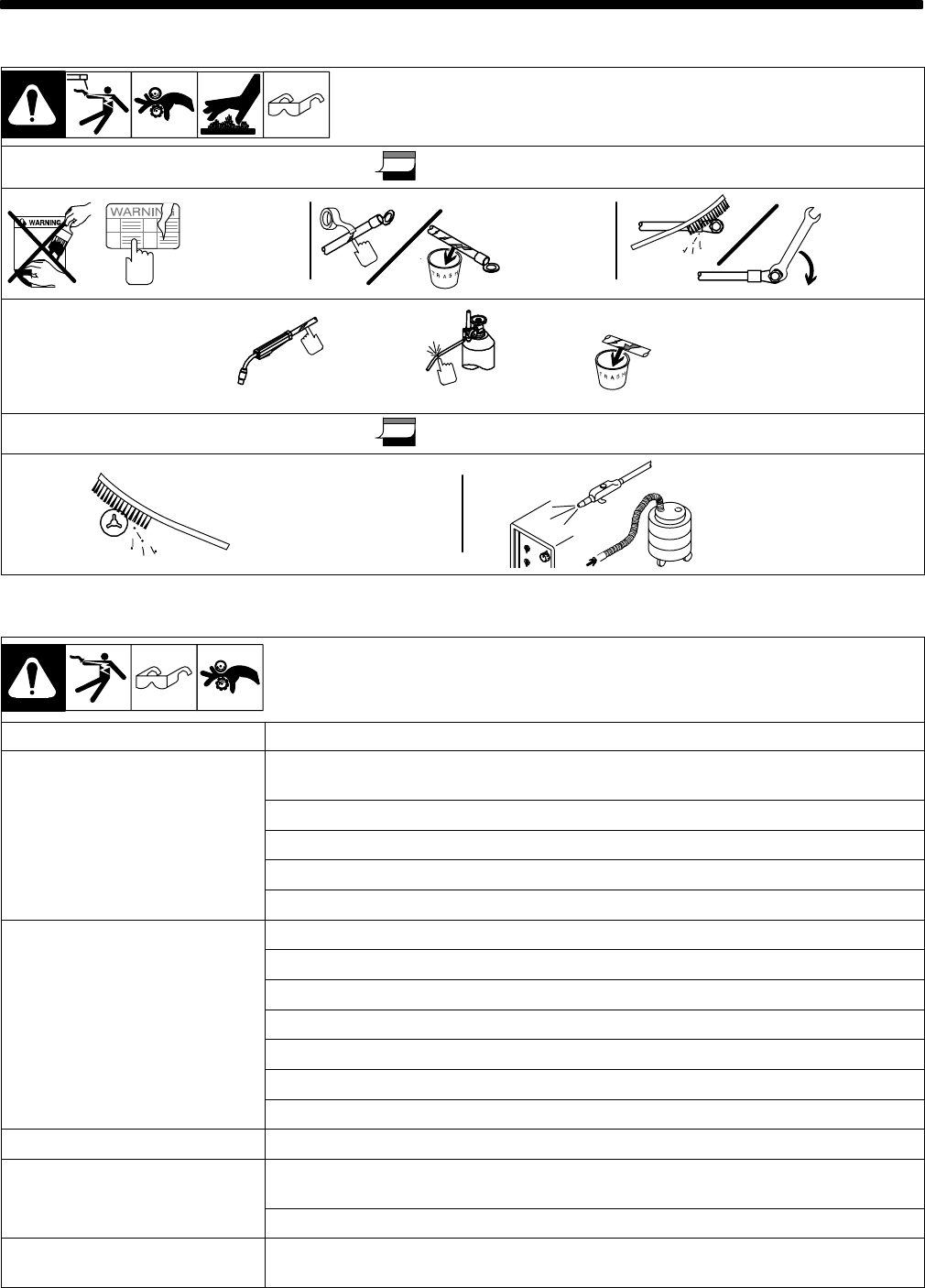

4-2. Troubleshooting

Trouble Remedy

Wire does not feed; open-circuit voltage

available.

Check circuit breaker CB1 and reset (see Section 3-1).

Check sensing lead connection.

Check gun trigger plug connection.

Check gun trigger. See gun Owner’s Manual.

Have Factory Authorized Service Agency check drive motor and control board PC1.

Wire feeds erratically. Readjust hub tension (see Section 2-6).

Readjust drive roll pressure (see Section 2-7).

Use correct size drive roll (see Parts Listing)

Clean or replace dirty or worn drive roll (see Section 2-2).

Remove weld spatter around nozzle opening.

Replace contact tube or liner. See gun Owner’s Manual.

Have Factory Authorized Service Agency check drive motor and control board PC1.

Wire feeds as soon as power is applied. Check gun trigger. See gun Owner’s Manual.

Wire stubbing on low end using a con-

stant current power source.

Make sure CC/CV switch is in CC position (see Section 3-1).

Increase output setting of power source.

Gas does not flow or does not stop flow-

ing; wire feeds.

Check optional gas valve. Have Factory Authorized Service Agency check drive and motor control board

PC1 and optional gas control board PC50.