OM-1078 Page 11

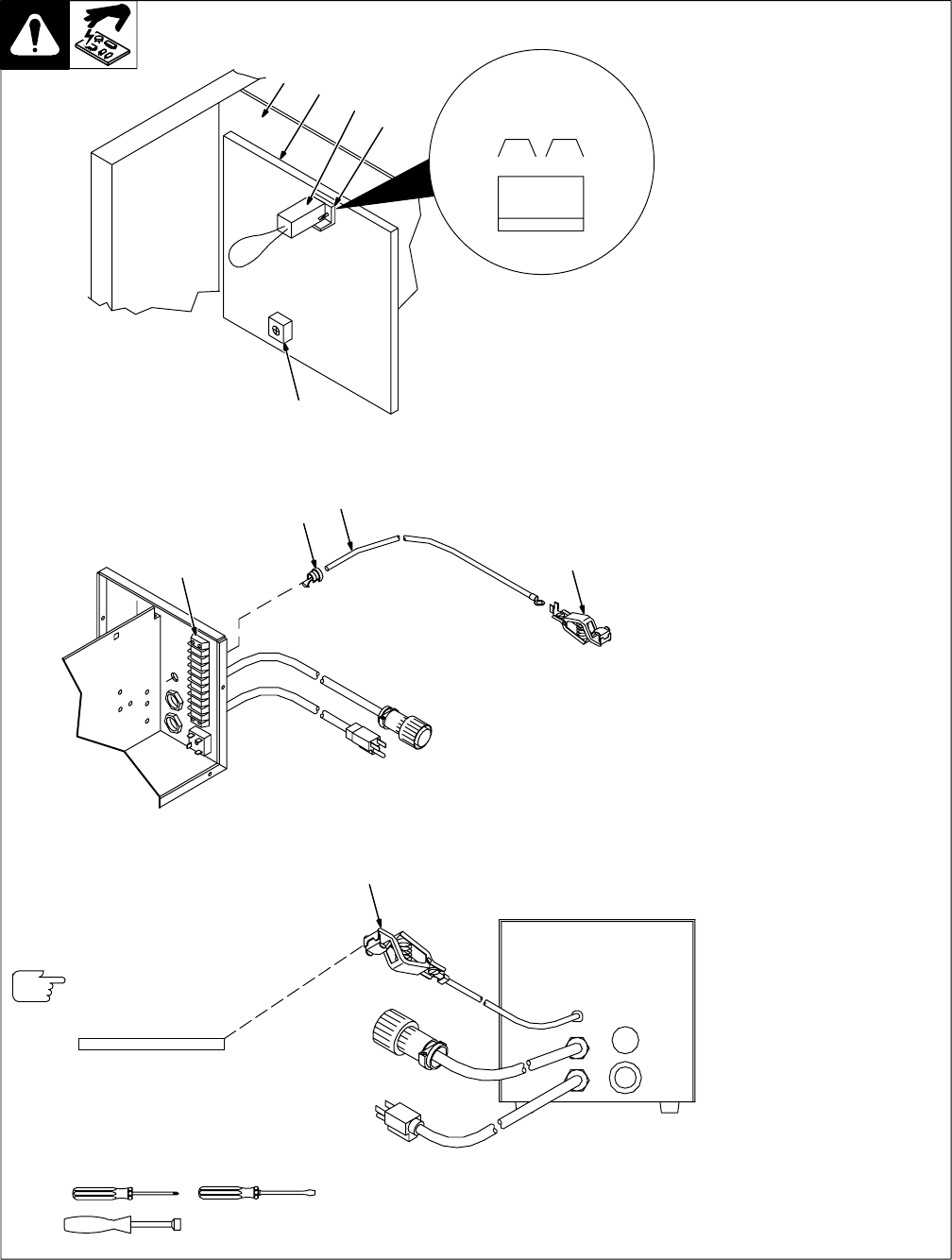

3-5. Installing Voltage Sensing Lead And Motor Start Control Adjustment

150 035-B / Ref. 143 328-K / 149 920-B

1 Center Baffle

2 Circuit Board PC1

3 Jumper Plug

4 Receptacle RC3

Internal (INT) and external (EXT)

are stamped on PC1 just above

RC3. Unit is shipped with jumper

plug in internal (INT) position.

To install voltage sensing lead,

proceed as follows:

5 Clamp

6 Cord

Connect ring terminal on end of

cord using screw in clamp. Crimp

clamp tabs around cord.

7 Strain Relief

Slide strain relief onto cord

approximately 6 in (152 mm) from

cord end.

Remove upper hole plug from rear

panel.

Insert cord into opening in rear

panel, and secure strain relief into

opening.

8 Terminal Strip 1T

Connect voltage sensing lead to

terminal strip 1TK at lead 42.

9 Voltage Sensing Lead

For constant current welding

(CC), place jumper plug in the

EXT position. Connect voltage

sensing lead to workpiece.

For constant voltage welding (CV),

place jumper plug in the INT

position. Do not install voltage

sensing lead.

10 Potentiometer R70

To adjust motor ramp speed,

remove protective cap (if present),

and adjust potentiometer R70 using

a small nonconductive screwdriver.

Rotating R70 clockwise increases

the time it takes the motor to ramp

up to speed.

Reinstall wrapper.

Tools Needed:

1/4 in

Front

1

2

3

4

10

123

INT. EXT.

RC3

CV CC

9

Rear View

For CC operation, connect

voltage sensing lead to

workpiece.

Work

. Contactor cord only

on standard model.

5

6

7

8